Is the choice of color affecting the functionality and appeal of your products? Zinc plating colors are not just an aesthetic choice; they play a crucial role in the durability and marketability of metal products.

With our deep-rooted expertise in the world of metal finishes, we provide valuable insights on zinc plating colors, essential for enhancing product quality and meeting industry standards.

Zinc plating colors offers more than just a visual upgrade; it’s about enhancing product resilience and market presence. These colors are becoming vital component in the strategic planning of metal fabrication and finishing.

In this guide, we will dive into the essentials of zinc plating colors, their benefits, various hues, trends, and maintenance tips, equipping you with the knowledge to make informed decisions.

Read on to explore the vibrant world of zinc plating colors.

1. The Basics of Zinc Plating Colors

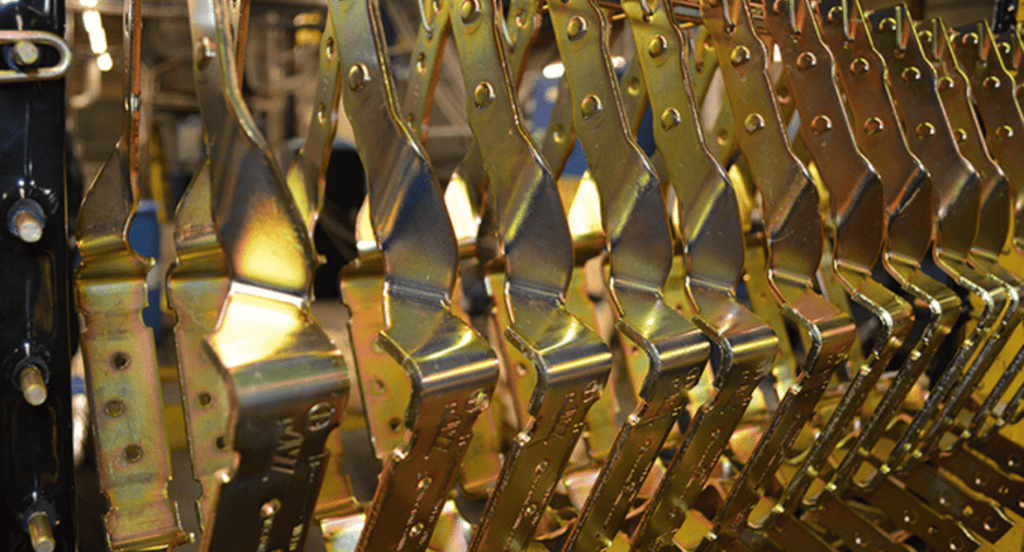

Zinc plating is a critical process where a layer of zinc is applied to a metal surface for enhanced protection and aesthetic value. This process not only guards against corrosion but also allows for the incorporation of various colors, offering both functional and visual benefits. The choice of color in zinc plating is not just about appearance; it significantly influences the environmental suitability and user interaction with the metal product.

Each color in the zinc plating spectrum is achieved through specific chemical processes and additives, resulting in a wide range of shades. These colors can be tailored to meet specific industry requirements or aesthetic preferences, making zinc plating a versatile option for various applications. Understanding these coloration techniques is crucial to optimizing metal products for performance, durability, and appeal.

2. Advantages of Colored Zinc Platings

Building on the basics of zinc plating colors, it’s essential to explore the significant benefits they offer, each contributing uniquely to the value and functionality of metal products. Here are the key advantages:

Improved Aesthetics

Colored zinc platings enhance metal product appearance, offering a diverse palette to complement any design. This versatility allows for customization of products to specific market trends and consumer preferences.The right color choice can make products visually striking, boosting appeal.

Enhanced Corrosion Resistance

Various colors in zinc plating offer different levels of corrosion resistance, making them valuable in environments exposed to corrosive elements. The choice of color plays a crucial role in extending the lifespan of products while enhancing their visual appeal.

Branding and Identification

Colored zinc plating is a valuable tool for branding and part identification. It helps associate specific colors with a brand, facilitating quick recognition and strengthening brand identity. In complex assemblies with many parts, color coding simplifies inventory management and assembly processes.

Assists in Thermal Management

Certain colors in zinc plating impacts thermal management by influencing heat absorption or reflection. For example, lighter colors reflect heat, while darker tones absorb it. This characteristic can be crucial in applications where temperature regulation is vital.

3. The Different Hues of Zinc Plating

After understanding the various advantages of colored zinc platings, it’s essential to dive into the specific hues available, each offering unique benefits and aesthetics. Here are its diverse and distinct colors:

Bright Silver

Bright silver zinc plating is renowned for its reflective, mirror-like finish, adding a stylish and sophisticated look to metal components. This hue is particularly effective for decorative and consumer products, where visual appeal is essential. Additionally, it provides a decent level of corrosion resistance, making it a practical choice for both form and function.

Matte Black

Matte black zinc plating is highly appreciated for its subtle elegance, offering a contemporary look ideal for automotive and electronic parts. Its non-reflective surface is beneficial for reducing bright reflections and enhancing usability in various applications. The color’s versatility and durability make it a top choice for combining appearance with practical needs.

Gold

Gold zinc plating is often chosen for its premium appearance in decorative electronics and ornamental items. Beyond its visual appeal, this hue is known for its corrosion resistance, making it a stylish and durable option. Its versatility allows for both aesthetic enhancement and functional longevity in high-end applications. Zemetal’s expertise in gold zinc plating ensures a perfect balance of style and durability in projects.

Blue Zinc

Blue zinc plating provides a vibrant and eye-catching finish, making it a popular choice for adding a distinctive touch to machinery and automotive components. Its corrosion-resistant properties are as impressive as its appearance, ensuring both beauty and longevity. This hue is especially favored for applications where both appearance and performance are critical.

Green Zinc

Green zinc plating stands out with its unique color, ideal for easy identification in complex assemblies and systems. This hue is not just visually appealing but also functional, facilitating better organization and tracking of components. Its use is particularly widespread in industries where color coding is crucial for efficiency and safety.

4. Customization and Trends in Zinc Plating

Bridging from the exploration of zinc plating hues, it’s time to dive into how customization and emerging trends are shaping the industry. Here are key areas where these trends are making a significant impact:

Integration of Digital Design Tools

The integration of digital design tools in zinc plating is a trend that’s bridging the gap between design and manufacturing. By employing metal design software to mimic and plan color schemes and finishes, precise and innovative outcomes can be achieved. This trend is particularly useful for prototyping and for visualizing the end product before the plating process begins.

Sustainable Coloring Processe

The shift towards sustainable coloring processes in zinc plating reflects a growing commitment to environmental responsibility in the industry. These methods prioritize the use of eco-friendly dyes and processes that reduce harmful emissions and waste. For example, utilization of water-based dyes and recycling systems in the plating processes can significantly lower ecological footprint.

Custom Color Matching

Custom color matching in zinc plating allows for unmatched design flexibility, catering to specific branding or product design requirements. This process involves precise adjustments to the plating solution and technique to achieve the desired hue. It’s a valuable tool for businesses looking to create a unique or signature appearance for their products.

Innovative Application Techniques

Innovative zinc plating methods are changing how colors appear on metal surfaces. These techniques involve new methods of layering, texturing, and combining colors for better results, both in terms of aesthetics and functionality. Zemetal stays at the forefront of these advancements, ensuring cutting-edge solutions for every plating needs.

5. Durability and Maintenance of Colored Zinc Plating

While the customization and trends in zinc plating offer exciting possibilities, it’s equally important to understand the durability and maintenance requirements of these to ensure their lasting impact. Here are tips for proper care:

Effective Cleaning Techniques

Efficient cleaning is crucial for maintaining the shine and integrity of colored zinc platings. Utilize gentle, non-abrasive cleaners to avoid damaging the surface. Regular cleaning not only enhances appearance but also helps in identifying any early signs of wear or corrosion.

Protection from Environmental Stress

Colored zinc coatings are vulnerable to environmental stressors like UV radiation, moisture, and pollutants. For example, implementing protective measures, such as applying sealants or using UV-resistant coatings, can significantly prolong the life of the plating. Tailoring these protective strategies to specific environmental conditions is key to effective maintenance.

“Implementing targeted protective measures is crucial to extending the lifespan of colored zinc coatings, as outlined in the table below.”

| Protective Measure | Description |

| Sealants | Application of sealants or topcoats to shield against moisture and environmental factors. |

| UV-Resistant Coatings | Usage of coatings designed to withstand UV radiation, preventing color fading and degradation. |

| Climate-Specific Strategies | Tailoring protective approaches based on specific environmental conditions for optimal defense. |

| Regular Maintenance | Periodic checks and maintenance to detect early signs of degradation and apply necessary measures. |

| Corrosion Inhibitors | Incorporating inhibitors to combat pollutants and corrosive elements, preserving coating integrity. |

Handling and Storage Practices

Proper handling and storage of items with colored zinc plating are critical to avoid scratches and other physical damages. Ensuring that these items are stored in a dry, temperature-controlled environment can greatly reduce the risk of degradation. Educating staff on best practices for handling can also play a significant role in maintenance.

Repair and Touch-Up Techniques

For maintaining the appearance and function of colored zinc coatings, effective repair and touch-up techniques are vital. Minor scratches and wear can be addressed with matching touch-up paints or additional plating processes. Timely repairs not only restore the coating’s appearance but also prevent further damage to the underlying metal.

6. Common Challenges and Solutions in Zinc Color Plating

Transitioning from durability and maintenance of colored zinc plating, it’s vital to acknowledge its challenges to ensure best quality and performance of final product. Here are common obstacles and their effective solutions:

Color Consistency

Achieving consistent color in zinc color plating across different batches can be challenging due to factors like chemical composition and process variables. To address this, establish strict control protocols, including monitoring chemical concentrations and maintaining consistent environmental conditions. Regularly conduct quality checks and color calibration against established standards to ensure uniformity in the final product.

Adhesion Issues

A common issue with colored zinc plating is the risk of poor adhesion, where the coating may not properly bond to the base metal, leading to peeling or flaking. To improve coating adhesion, focus on thorough surface preparation, including cleaning and using appropriate primers or undercoatings. Additionally, adjust plating conditions like temperature and pH, and use adhesion-promoting chemicals for stronger bonds.

Meeting Specific Industry Requirements

The challenge in meeting specific industry requirements lies in the diverse and often strict standards that vary significantly across sectors. To address this, it’s crucial to conduct thorough research into each industry’s unique specifications and regulatory demands. Tailoring the plating process to these requirements, often through collaboration with industry experts, ensures compliance and customer satisfaction.

Innovations in Plating Technology

The traditional methods of zinc color plating often face limitations in efficiency and environmental sustainability. To improve plating processes adopt modern technologies like automated systems, eco-friendly chemicals, and precise control mechanisms. These innovations simplify plating, reduce environmental impact, and boost coating quality.

7. 4 Tips for Choosing the Right Color for Your Zinc Plating Needs

As per Data Intelo, the zinc plating market will see steady growth at a 4.5% CAGR from 2018 to 2028, driven by automotive and home appliance demand. Here are essential tips to choose the right color for your zinc plating:

#1 Evaluating Project Requirements

Before selecting a zinc plating color, thoroughly evaluate the specific requirements of the project. Consider the operational environment, including factors like mechanical stress, exposure to elements, and interaction with other materials. This initial assessment will guide you towards colors that not only look good but also perform optimally under specific operational circumstances.

#2 Color Durability Considerations

Durability is a key factor in selecting the right zinc plating color. Different colors may exhibit different levels of resistance to fading, chipping, or corrosion in various environments. Assess the longevity and maintenance requirements of each color option, ensuring that the choice aligns with the expected lifespan and usage conditions of the plated item.

#3 Aesthetic vs. Functional Priorities

Balancing aesthetics with functionality is essential in the selection process. While the visual appeal is important, it should not compromise the practical applications of the plated item. Carefully weigh the visual impact of the color against its functional benefits, such as visibility in operational settings or compliance with industry standards.

#4 Cost-Benefit Analysis

Consider the cost implications of different zinc plating colors. Some colors might require more expensive materials or complex processes, impacting the overall cost of the plating project. Analyze the benefits of each color option in relation to the additional costs involved, making sure it is a cost-effective decision.

Conclusion

The exploration into zinc plating colors showcases a world where functionality meets aesthetics, offering a strategic edge in product design and protection. This guide has served as a valuable resource, equipping you with essential knowledge and strategies for selecting the ideal color for your projects.

If you are seeking to elevate your metal finishing projects with the right touch of color and quality, Zemetal is your go-to expert. Contact us to explore our zinc plating options and elevate your projects.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.