What is laser engraving? It’s a precise process where high-powered lasers are used to etch designs, patterns, or text onto different materials with exceptional accuracy.

As a Jeweler, I often get asked about how laser engraving can add intricate, custom details to metal surfaces and other materials.

Don’t worry, the process is straightforward and highly effective for creating detailed designs without damaging the material.

In this guide, you will learn how laser engraving works, its various applications, and why it has become a preferred method in industries that require precision and durability. This knowledge will help you understand how it can benefit your projects.

So let’s begin!

1. The Science Behind Laser Engraving

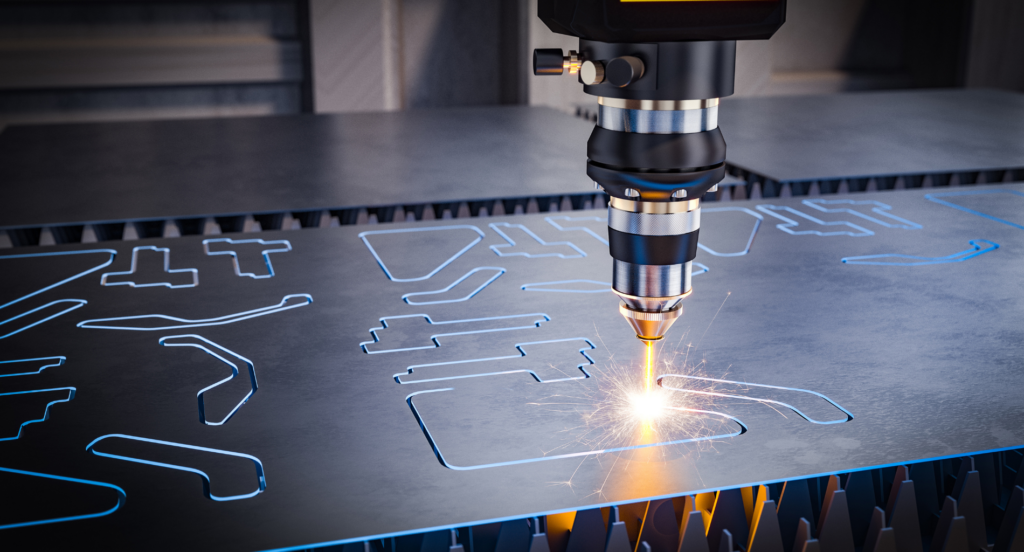

Laser engraving in metal fabrication is a fascinating interplay of light and material. At its core, it involves a highly focused laser beam that precisely removes layers from the metal surface. This process creates detailed designs and text without any physical contact, ensuring accuracy and minimal material distortion. Elevate your metal fabrication projects with laser engraving, where precision meets artistry to create unmatched quality.

The technology depends on the concept of controlled material vaporization. The laser beam, which is a concentrated form of light, heats up the metal surface to a point where it vaporizes. This precise control of the laser allows for intricate patterns and detailed engravings on various metals, from aluminum to stainless steel. The result is a permanent, high-resolution mark, ideal for both functional and decorative purposes.

2. Benefits of Laser Engraving in Metal Fabrication

Building on the intricate science of laser engraving, this technology offers an excess of benefits in metal fabrication. Here are the key advantages:

Enhanced Precision and Detail

Laser engraving allows for extraordinary precision, unmatched by traditional engraving methods. It can produce extremely fine details, perfect for complex logos or intricate patterns. This precision leads to high-quality finishes, essential for specialized industries. Additionally, the consistency of laser engraving ensures uniformity in mass-produced items.

Durability and Longevity

Engravings made with laser technology are known for their durability. Unlike surface-level marks, laser engravings are deeply embedded into the metal, making them resistant to wear and tear. This permanence is particularly beneficial for items subjected to harsh conditions or heavy use. Furthermore, laser engravings do not fade over time, maintaining their clarity and legibility.

Cost-Effectiveness and Efficiency

Laser engraving is a cost-effective solution in the long run. It minimizes waste by using less material and reduces the need for additional finishing processes. The speed and automation of laser engraving machines also translate to higher productivity and lower labor costs. For businesses, this means quicker turnaround times and the ability to handle large orders efficiently.

3. Materials Compatible with Laser Engraving

The benefits of laser engraving, such as precision and cost-effectiveness, extend to a wide range of materials in metal fabrication. Here are some of the key materials that are particularly suited for laser engraving:

Stainless Steel

Stainless steel is a popular choice for laser engraving, owing to its durability and resistance to corrosion. Laser engraving on stainless steel results in clear, precise, and permanent markings, making it ideal for industrial and commercial applications. For example, stainless steel surgical tools are often laser engraved for easy identification. Surprisingly, this is also widely used for engraving barcodes, serial numbers, and logos.

Aluminum

With the aluminum market projected to grow to $210 billion by 2027 reported by Statista, its use in laser engraving applications is increasingly significant. This material’s lightweight yet durable characteristics, making the laser engraving process of aluminum efficient, producing precise markings. This makes aluminum ideal for automotive parts and electronic components, reflecting its growing market value and wide-ranging utility.

Brass and Copper

Brass and copper are highly favored in laser engraving for their aesthetic appeal. These materials are often used in decorative applications, where the contrast created by the engraving enhances their natural beauty. Engraving on brass and copper is about aesthetics and functionality, as it is used in nameplates, and memorial markers. The laser engraving process on these materials is smooth and yields high-resolution results.

4. Equipment and Tools for Laser Engraving

Transitioning from the materials compatible with laser engraving, the effectiveness of this process significantly depends on the equipment and tools used. Let’s explore the equipment and tools needed for laser engraving:

Laser Engraving Machines

Laser engraving machines are the heart of the engraving process. They come in various sizes and power levels to accommodate different materials and thicknesses. These machines are equipped with advanced software that controls engraving precision and depth. High-quality laser engravers ensure consistent results, making them indispensable for professional metal fabrication.

This table details the key features and benefits of laser engraving machines:

| Feature | Description | Benefit in Metal Fabrication |

| Size Variability | Available in multiple sizes for diverse needs | Accommodates different material sizes |

| Power Levels | Range of power options for material thickness | Ensures suitability for various metals |

| Advanced Software | Controls precision and depth of engraving | Enhances accuracy and detail |

| Consistency | Delivers uniform results across applications | Crucial for professional-quality work |

| Versatility | Capable of engraving a variety of designs | Broadens the scope of fabrication tasks |

Cooling Systems

Proper cooling systems are crucial for maintaining the longevity and performance of laser engraving machines. They prevent overheating and potential damage to both the machine and the material being engraved. Water-based cooling systems are commonly used due to their efficiency in dissipating heat. Regular maintenance of these systems is essential to ensure uninterrupted operation.

Fume Extraction Systems

Laser engraving can produce harmful fumes, especially when working with metals. Fume extraction systems are necessary to maintain a safe working environment. They filter out harmful particles and fumes, ensuring the health and safety of operators. These systems also help in maintaining the clarity of the laser for consistent engraving quality.

Software for Design and Control

Software plays a critical role in laser engraving. It allows for the design of intricate patterns and controls the laser’s movement and intensity. User-friendly software enhances the efficiency of the engraving process. For example, CAD (Computer-Aided Design) software is commonly used for creating detailed designs that are then precisely executed by the laser engraver.

5. Laser Engraving Applications in Different Industries

With the right equipment and tools, laser engraving in metal fabrication finds its applications across various industries. These applications vary widely, demonstrating the versatility of this technology. Here are the different industries it can apply:

Aerospace Industry

In the aerospace industry, laser engraving is vital for part identification and traceability. It is used to engrave serial numbers, identification codes, and logos on aircraft components. The precision of laser engraving ensures that these markings are clear and durable, even under extreme conditions. This is crucial for safety, maintenance, and regulatory compliance in the aerospace sector.

Medical Equipment Manufacturing

Laser engraving plays a critical role in the medical equipment manufacturing industry. It is used to mark surgical tools, implants, and other medical devices with crucial information like serial numbers, manufacturer details, and usage instructions. The non-contact nature of laser engraving ensures sterility, while the permanence of the markings is essential for traceability and patient safety.

Automotive Industry

In the this industry, laser engraving is used for both functional and aesthetic purposes. It’s employed to mark components with serial numbers and manufacturing information, aiding in traceability. Laser engraving is also used for customizing vehicle parts, such as dashboards and VIN plates, adding a unique touch to high-end vehicles. The precision of laser engraving makes it ideal for the demanding conditions of the automotive sector.

6. Cost Analysis and Budgeting for Laser Engraving

The diverse applications of laser engraving in different industries necessitate an understanding of its cost analysis and budgeting. Let’s have a detailed analysis on laser engraving cost:

Initial Investment in Equipment

The cost of laser engraving equipment varies widely. Entry-level machines can range from $3,000 to $10,000, suitable for small-scale operations. Mid-range models, offering better capacity, can cost between $10,000 to $40,000. For high-end, industrial-grade machines, prices can soar above $40,000, designed for heavy-duty use and larger production volumes. This range reflects the diversity in machine capabilities and intended usage.

Operating and Maintenance Costs

Operating costs typically include electricity, which may range from $50 to $200 monthly, depending on usage intensity. Maintenance costs, including parts replacement, can add an annual expense of $500 to $2,000. Additionally, cooling systems essential for larger machines, can increase operational costs by up to 10-20%. Regular maintenance is crucial for efficiency, and these costs should be factored into the budgeting process.

Material and Supply Costs

Material costs depend on the type of metal used for engraving. For instance, stainless steel prices can fluctuate, averaging $15 to $50 per square foot, depending on quality and market conditions. Consumables like lenses and filters might cost between $100 to $500 annually. These costs vary based on usage frequency and the scale of operations, making efficient material management a key factor in controlling expenses.

7. Challenges in Laser Engraving

While laser engraving is a cost-effective solution, it comes with its own set of challenges that businesses in metal fabrication need to navigate. Let’s explore these challenges:

Material Limitations

Despite its versatility, laser engraving has limitations with certain materials. Metals with high reflectivity, like copper and silver, can be challenging to engrave as they reflect the laser beam. This can lead to inconsistent engraving quality and potential damage to the laser system. Finding the right laser parameters for different metals requires experimentation and expertise, adding to the complexity of the process.

Technical Expertise Required

Laser engraving requires a certain level of technical skill and understanding. Operators need to be trained in handling the equipment, software, and material properties. The learning curve can be steep, especially when dealing with complex designs or large-scale projects. Additionally, maintaining the delicate balance between speed, power, and focus is crucial for optimal results, necessitating skilled operators.

Maintenance and Upkeep

Regular maintenance is essential for laser engraving machines to function effectively. This includes cleaning lenses, aligning lasers, and replacing worn-out parts. Neglecting maintenance can lead to decreased efficiency and accuracy, and in severe cases, machine breakdown. The cost and effort involved in upkeep can be a challenge, especially for smaller businesses with limited resources.

8. 3 Tips for Choosing the Right Laser Engraving Services

Navigating the challenges of laser engraving in metal fabrication, it’s vital to select the right service provider. Here are the tips that you should consider:

#1 Assessing Technical Capability

When choosing a laser engraving service, first evaluate their technical capabilities. Zemetal have advanced, well-maintained machines that can handle the specific requirements of your project. Additionally, check if they can work with a variety of metals and if they have experience in creating the type of designs you need. A service provider with a diverse range of capabilities is more likely to deliver high-quality results.

#2 Reviewing Portfolio and Experience

Examine the service provider’s portfolio and past projects. This will give you an insight into their expertise and the quality of work they can produce. Look for experience in your specific industry, as this indicates an understanding of industry-specific standards and requirements. A strong portfolio with relevant experience is a good indicator of a reliable and skilled service provider.

#3 Evaluating Customer Service and Communication

Choose a service provider who is responsive, willing to discuss your needs in detail, and offers clear communication throughout the project. Provider’s like Zemetal provide guidance, make recommendations, and keep you informed about the progress of your projects. Effective communication ensures that your project will be completed according to your expectations and within the set timelines.

Conclusion

If you’re facing challenges with creating precise and detailed designs on various materials, laser engraving could be the solution you’ve been looking for. It offers unmatched accuracy and flexibility, making it ideal for intricate projects. At Zemetal, we specialize in offering high-quality laser engraving services that meet your specific needs.

In conclusion, this guide has shown you the ins and outs of laser engraving, explaining how it works and its many benefits. With this knowledge, you can better understand how this process can elevate your projects. Contact us today to learn more about how we can help you achieve precision and excellence with laser engraving.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.