What is Geomet? It’s a water-based, zinc-rich coating used to protect metal surfaces from corrosion, offering long-lasting durability in harsh environments.

As an Industrial Coating Specialist, I often get asked about Geomet and why it’s a popular choice for metal protection in various industries.

Don’t worry, the process is straightforward and highly effective in extending the life of metal components.

In this guide, you will learn what Geomet is made of, how it works, and why it’s a great option for safeguarding metal against corrosion.

So let’s get down to it!

1. Defining Geomet

Geomet is a water-based, zinc-rich coating predominantly utilized in the metal fabrication industry. Its primary function is to provide superior corrosion resistance to various metals. The coating is composed of zinc and aluminum flakes bonded in a silicate matrix. This unique composition offers enhanced protection against environmental factors.

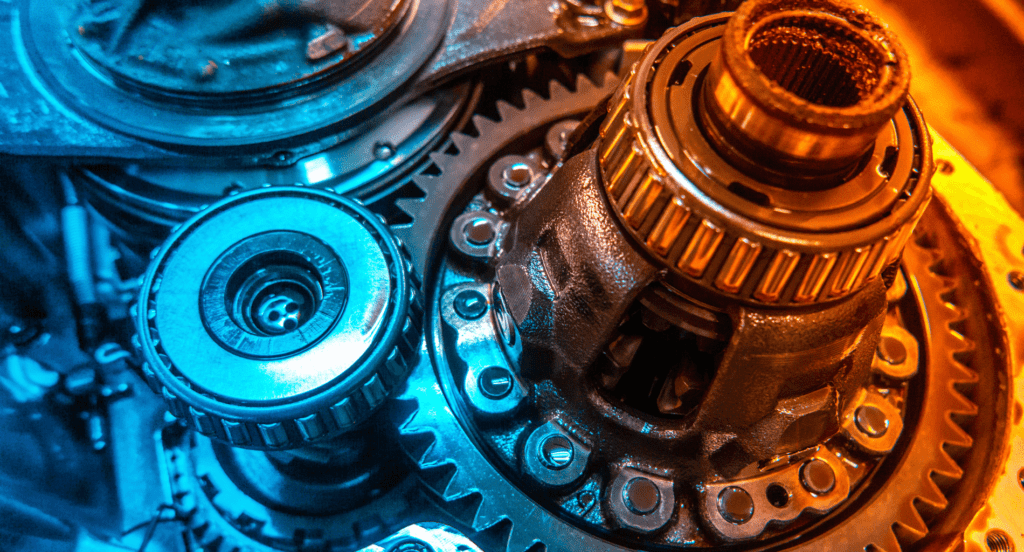

In metal fabrication services, geomet serves as a non-electrolytic coating. It’s applied using a simple dipping or spraying process, making it convenient and efficient. The coating adheres well to surfaces, providing a durable, uniform layer. Its versatility allows for application on a wide range of metal products, from automotive parts to building materials.

2. Benefits of Using Geomet

Building on our understanding of Geomet from the definition, let’s delve into its numerous benefits in metal fabrication services that can be a compelling choice for many in the industry. Here are some key benefits:

Corrosion Protection

Geomet offers unparalleled corrosion protection, which is crucial for metal products exposed to harsh environments. Its zinc-rich composition acts as a barrier, significantly slowing down the corrosion process. This protection ensures a longer lifespan for metal components, reducing the need for frequent replacements. Industries with high exposure to corrosive elements can highly appreciate this benefit.

Eco-Friendly and Safe

In today’s environmentally conscious world, geomet stands out as a non-toxic option. It’s free from heavy metals and volatile organic compounds, making it safer for workers and the environment. This eco-friendly aspect helps companies meet regulatory standards which appeals to consumers looking for sustainable products. Choosing geomet means showing commitment to health, safety, and environmental stewardship.

Versatility in Application

Geomet’s compatibility with various metals makes it a versatile choice for many fabrication projects. Whether it’s applied through dipping or spinning, the process is efficient to different manufacturing workflows. For example, in the automotive industry, geomet is used on a wide range of parts, showing its extensive use. This flexibility makes it a choice for fabricators like Zemetal seeking a reliable, multi-purpose coating solution.

3. The Process of Applying Geomet

Transitioning from the benefits of using geomet, it’s important to understand the steps involved when applying geomet. Variations of these steps can be adapted based on the project’s needs. Here’s a detailed exploration of this process:

Step#1 Surface Preparation

The first step is ensuring the metal surface is clean and free from any contaminants. This usually involves a process of degreasing, washing, and then drying the metal. A clean surface ensures that the geomet coating adheres properly and performs effectively. Proper preparation is the foundation for a successful application.

Step#2 Application of Coating

Once the surface is prepared, the geomet coating is applied. This can be done through dipping, spraying, or spinning, depending on the size and shape of the metal piece. The application must be even and consistent to ensure complete coverage. Zemetal ensures precision in this step in order to achieve the desired level of corrosion protection in their products.

Step#3 Baking the Coating

After the geomet is applied, the metal is baked at a high temperature. This process helps the coating to cure and bond firmly to the metal surface. The specific temperature and time can vary, but precise control is necessary to achieve the best results. This step solidifies the coating’s durability and protective qualities.

Step#4 Quality Inspection

Once the coating has cured, a thorough quality inspection is conducted. This might involve visual checks, thickness measurements, and adhesion tests. Ensuring the coating’s uniformity and integrity is essential for long-term performance. Any defects or inconsistencies can be addressed at this stage before the final product is approved.

Step#5 Final Touches and Assembly

After passing the quality inspection, the geomet-coated parts are ready for any final touches, such as additional layers. For example, a geomet-coated brake rotor might receive a topcoat for extra protection and aesthetic appeal. Once all coatings are complete, the parts can be assembled into the final product. This step showcases the practical application of geomet in enhancing the performance of metal components.

4. Applications of Geomet in Various Fields

Moving from the process of applying geomet, let’s explore how its is being applied across various industries. Here are the fields that geomet’s versatility are highly recognized:

Automotive Industry

In the automotive sector, Geomet is crucial for enhancing the longevity and safety of vehicles. It’s commonly used on components like brake rotors, fasteners, and chassis parts to prevent rust and wear. This application ensures that vehicles remain reliable and durable over time, even under harsh driving conditions. The automotive industry values geomet for its ability to maintain the integrity and performance of critical parts.

Construction Industry

In the construction industry, where geomet is essential for protecting materials, the sector’s expected hit a CAGR of 5.3% from 2022 to 2027, as reported by Technavio, highlights the increasing importance of corrosion-resistant solutions. This growth shows the importance of geomet coating in structural steel, and other building materials, essential in maintaining the integrity of structures exposed to harsh environmental conditions.

Energy and Utilities

In the energy and utilities sector, geomet is applied to equipment and components like wind turbines, pipelines, and electrical hardware. The coating protects against corrosion, which is a major concern in environments exposed to the elements. With geomet, the lifespan of these structures is significantly extended, reducing maintenance costs.

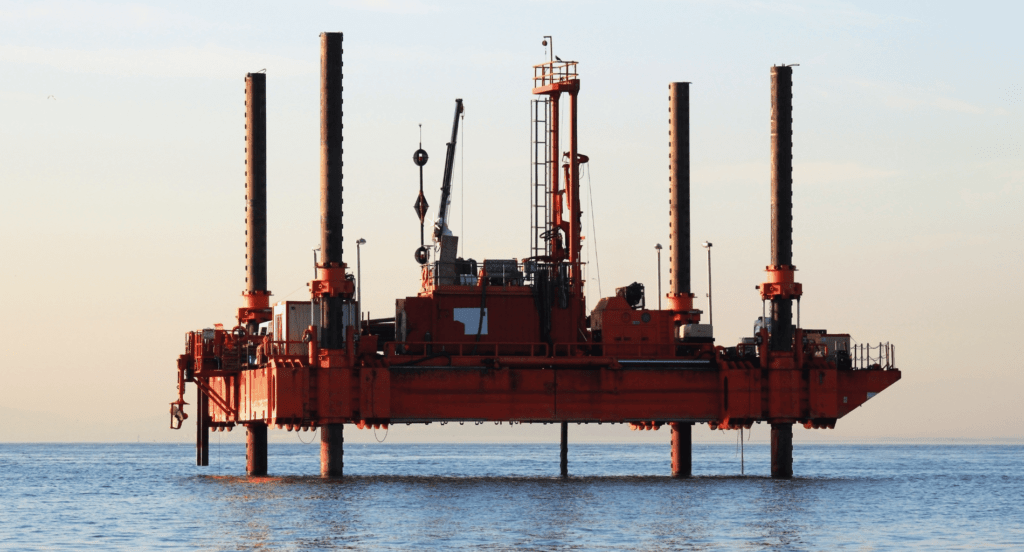

Marine and Offshore

The marine and offshore industry benefits greatly from geomet’s corrosion-resistant properties. It’s used on ships and port equipment to protect against the corrosive effects of seawater and marine atmosphere. This application not only extends the service life of these assets but also ensures their safety and reliability. Geomet’s ability to withstand harsh marine conditions makes it an indispensable solution in this sector.

5. Comparing Geomet with Other Coatings

As we’ve seen the extensive applications of geomet in various fields, it’s valuable to understand how it compares with other coatings used in the metal fabrication industry. Below is a comparison table featuring Geomet alongside four other popular coatings:

| Coating Type | Characteristics | Benefits | Considerations |

| Geomet | Water-based, zinc-rich coating. Non-toxic and environmentally friendly. Offers excellent corrosion resistance. | Eco-friendly, versatile application, superior corrosion protection. | May require topcoat for UV protection in certain applications. |

| E-coat | An electrically applied paint or lacquer. Known for uniform coverage. | Provides a consistent finish, good coverage in recessed areas, and is relatively cost-effective. | Less effective in harsh environments, potential chipping. |

| Galvanizing | A process of applying a protective zinc layer by dipping metal in molten zinc. | Extremely durable, long-lasting protection, and economical for large structures. | Difficult to apply on complex shapes, environmental concerns. |

| Powder Coating | A dry powder applied electrostatically and cured under heat. | Wide range of colors and finishes, durable, and resistant to chipping, scratching, and fading. | Requires high-temperature curing, not as flexible as liquid coatings. |

| Anodizing | An electrolytic passivation process used to increase the thickness of the natural oxide layer on metal surfaces. | Durable, resistant to corrosion, enhances aesthetic appeal, and can color the metal. | Primarily for aluminum, can be costly, color inconsistencies. |

When selecting a coating for metal fabrication, it’s crucial to consider the specific requirements of the application, including environmental conditions and budget constraints. Geomet, with its balanced properties, often serves as an efficient choice for businesses seeking a mix of performance. However, each coating has its niche where it performs best, and the final decision should be based on an analysis of needs and costs.

6. Challenges and Controversies in Geomet

Acknowledging the comparisons of geomet with other type of coatings, it’s also crucial to deal with the specific challenges and controversies that have emerged. Here are detailed insights into these issues:

Integration with Other Systems

Integrating geomet with other systems and technologies used in metal fabrication can be problematic. Compatibility issues may arise, leading to data inaccuracies and workflow disruptions. Ensuring seamless integration is essential for maintaining efficiency and accuracy in production. Ongoing development and customization of geomet are necessary to enhance its interoperability with other industry tools.

Reliability and Standardization Issues

The reliability of geomet’s measurements and the lack of standardization across different platforms have sparked controversy. Professionals debate over which systems provide the most accurate and reliable results. This lack of consensus can lead to mistrust in the data provided by geomet, affecting decision-making and product quality.

Intellectual Property Concerns

There are controversies surrounding the intellectual property rights of geomet, particularly regarding its algorithms and methodologies. Competing companies may claim ownership over certain aspects of the technology, leading to legal disputes and uncertainty. These controversies can hinder innovation and collaboration within the industry, as companies might be hesitant to share their advancements.

7. 3 Factors to Consider When Choosing Geomet

Reflecting on the challenges and controversies of geomet, it’s important for potential users to weigh various factors carefully. Here are the key considerations when deciding whether geomet is the right choice for your needs:

#1 Application Environment

Consider the environment in which the coated product will be used. Geomet excels in corrosion resistance, making it ideal for harsh, corrosive environments. However, if the application involves prolonged direct UV exposure, remember that an additional topcoat will be necessary. Understanding the specific conditions your product will face is crucial in determining if geomet is the most effective solution.

#2 Environmental and Safety Regulations

Ensure that your use of geomet aligns with all relevant environmental and safety regulations. While geomet is more environmentally friendly than many coatings, it’s still essential to understand any potential risks and regulatory requirements associated with its use and disposal. Compliance with these regulations not only ensures safety but also protects your business from potential legal issues.

#3 Compatibility with Your Products

Finally, assess the compatibility of geomet with the specific metals and products you work with. Consider factors like the metal type, product shape, and the desired finish. Geomet works well with a wide range of metals and applications, but ensuring it meets the specific needs and standards of your products is crucial for achieving the desired performance and quality.

Conclusion

Protecting metal surfaces from corrosion can be a tough challenge, especially when durability is key. You want a coating that lasts without compromising quality. At Zemetal, we provide Geomet coating solutions that meet your exact needs, offering long-lasting protection.

In conclusion, this guide has covered the basics of Geomet and how it helps shield your materials from corrosion. If you’re ready to improve the lifespan of your metal products, reach out to us today. Zemetal is your go-to expert for top-tier Geomet coating services.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.