How does your product outshine its competition, positively? Electroplating is a critical process that transforms the ordinary into the exceptional, granting endurance and elegance to a wide array of items.

With extensive experience and a keen eye for industry evolution, I bring you insights grounded in practical knowledge and a commitment to quality. Let this guide serve as your beacon in the world of metal fabrication and finishing.

Here is a sneak peek at the 2 best uses of electroplating nowadays:

- Jewelry Enhancement

- Automotive Rust Protection

In this guide, we will delve into the 9 important applications of electroplating, uncovering how each contributes to product performance and industry standards.

Read on to uncover the full spectrum of electroplating’s potential.

1. Jewelry Enhancement

Electroplating is a transformative process that significantly enhances the aesthetic and value of jewelry. For instance, by depositing a thin layer of precious metal over a less expensive base, it allows for an increase in beauty without a substantial cost increase. This method provides a variety of color and finish options, enabling designers to create unique designs.

Beyond aesthetics, electroplating adds a protective layer to jewelry, guarding against tarnish and wear. It ensures the longevity of the piece, maintaining its luster over time. This process is especially beneficial for pieces that are worn frequently, as it significantly reduces the rate of wear-tear. Ultimately, electroplating elevates the quality jewelry, making it a wise investment for both manufacturers and consumers.

2. Automotive Rust Protection

Electroplating plays a crucial role in automotive rust protection, serving as a steadfast barrier against corrosion and wear. By applying a thin layer of corrosion-resistant metal like zinc or nickel onto automotive parts, it significantly extends their lifespan. This process is particularly vital for components exposed to harsh conditions, such as undercarriage parts and engine components.

In addition, electroplating enhances the vehicle’s overall appearance with a sleek finish. It’s not just about functionality; it’s about maintaining aesthetic appeal and vehicle value over time. This protective layer is cost-effective, reducing the need for frequent replacements and repairs. By investing in electroplating, automakers ensure a longer, more durable life for their vehicles, benefiting both the manufacturer and the consumer.

3. Electrical Connectors in Electronics

Electroplating is required in enhancing the performance and longevity of electrical connectors in electronics. By coating connectors with metals like gold or silver, it ensures a reliable and efficient electrical connection, crucial for the functionality of electronic devices. This process improves conductivity and prevents corrosion, a common issue that can lead to connection failures and device malfunctions.

Moreover, the precise nature of electroplating allows for uniform coverage, even on complex geometries, ensuring every part of the connector is protected. This uniformity is vital in maintaining consistent performance across all connectors in a device. It gives a more reliable, durable electronic product, with connectors that maintain their integrity and performance over extended use.

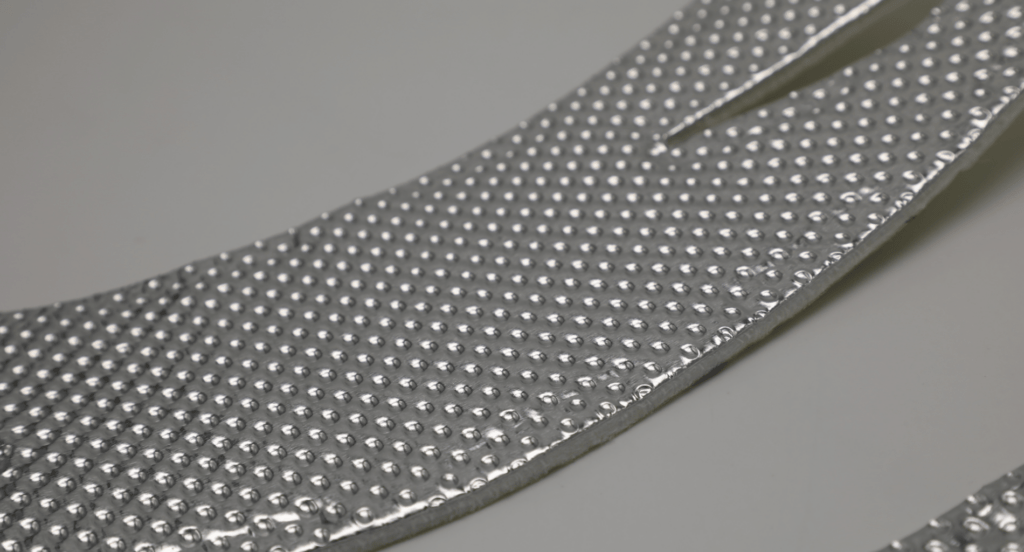

4. Tool Hardening

Tool longevity and performance see a remarkable improvement with the application of electroplating for hardening purposes. Metals such as nickel or chromium, when electroplated onto tools, create a robust surface capable of resisting wear and corrosion. This hardening is crucial for tools subjected to continuous and heavy usage, ensuring they maintain their shape and effectiveness over prolonged periods.

This process not only significantly extends the tool’s usable life but also preserves its precision and operational efficiency. A harder tool means a more durable and reliable piece of equipment, leading to fewer replacements and reduced operational disruptions. Tailoring the electroplating to the tool’s specific requirements ensures that it performs optimally for its intended tasks, providing both quality and longevity.

5. Aerospace Heat Shields

In the aerospace industry, heat shields are critical components, and electroplating significantly contributes to their performance. By applying a metallic coating, such as gold or silver, these shields can reflect radiant heat effectively, protecting the spacecraft’s sensitive components. Zemetal’s expertise in electroplating enhances this protective capability, ensuring the shields remain lightweight, an essential factor in aerospace engineering.

The electroplated coatings also provide excellent thermal stability and can withstand extreme temperature fluctuations experienced during space missions. This durability ensures the shield’s longevity and reliability, essential in an environment where maintenance is not an option. As a result, electroplating is enhancing the shield’s performance, ensuring the safety and success of aerospace missions.

6. Restoration of Vintage Items

The restoration of vintage items often involves returning their lost luster and integrity, a task where electroplating plays a vital role. By applying a fresh layer of metal, such as silver or gold, to worn or tarnished pieces, electroplating can rejuvenate their appearance and protect them from further degradation. This process is particularly valuable for antique items, where preserving the original look is essential.

Beyond aesthetics, electroplating restores the functionality of vintage metal items, reinforcing weakened areas and preventing future corrosion. It’s a delicate balance of respecting the item’s historical value while enhancing its durability with modern techniques. The end result is a beautifully restored piece that can withstand the test of time, ready to be appreciated by future generations.

7. Medical Device Coating

According to Yahoo Finance, the market of medical devices is expected to reach $656 billion, which highlights the importance of electroplating in terms of meeting stringent hygiene and performance standards. By applying metals like gold or silver known for their antimicrobial properties, electroplating ensures that devices are safe and resistant to bacteria. This is crucial in medical settings where preventing infection is paramount.

Additionally, the durability imparted by electroplated coatings extends the life of medical devices, ensuring they perform reliably over time. This process also allows for the fine-tuning of surface properties, such as reducing friction for needles or improving wear resistance for surgical tools. Electroplating, therefore, enhances the safety of medical devices and increase their reliability in critical healthcare settings.

8. Wear Resistance in Machinery

Enhancing the wear resistance of machinery is a crucial application of electroplating, ensuring machines can operate efficiently. By coating moving parts with hard metals like chromium or nickel, electroplating significantly reduces the wear and tear caused by friction. This is especially vital in high-use industrial settings where machinery downtime can lead to significant productivity losses.

Zemetal employs electroplating to protect and extend the life of their machinery, ensuring continued precision and performance. As the electroplated coating takes the brunt of the wear, the underlying machinery remains intact and functional. Consequently, electroplating is not just an investment in the durability of machinery but also in maintaining consistent quality and output in industrial operations.

This table details the role of electroplating in enhancing wear resistance in machinery, as practiced by Zemetal, to ensure long-term efficiency and productivity.

| Aspect | Description | Significance in Machinery Maintenance |

| Coating with Hard Metals | Applying chromium or nickel for durability | Reduces wear and tear from friction |

| Protection of Moving Parts | Targeting high-friction components | Extends lifespan of critical machinery parts |

| Minimization of Machinery Downtime | Reducing the need for frequent repairs | Maintains continuous industrial productivity |

| Preservation of Underlying Machinery | Electroplated layer absorbs most wear | Protects the integrity of the machinery |

| Consistent Quality and Output | Maintains machinery performance for quality assurance | Ensures reliability in industrial operations |

9. Enhancing Home Appliances

Electroplating significantly enhances the aesthetic and functional aspects of home appliances, making them more durable and visually appealing. For example, an application of chrome or nickel, appliances gain a sleek, modern finish with a protective barrier against rust and corrosion. This is particularly beneficial in environments like kitchens and bathrooms, where humidity and frequent use can take their toll.

Moreover, the electroplated coating on appliances ensures easy cleaning and maintenance, a vital aspect for any homeowner. The smooth, non-porous surface resists stains and buildup, keeping appliances looking new for longer. As a result, electroplating enhances the overall user experience, making it a valuable process for modern home equipment.

Conclusion

Electroplating is a versatile technique with far-reaching benefits across industries, as this guide has illustrated. From enhancing jewelry to protecting crucial machinery, the applications are as varied as they are vital.

For businesses seeking to harness the full potential of electroplating, Zemetal is your go-to expert. Contact us to explore how our electroplating solutions can transform your products and processes.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.