Are you leveraging the full potential of your sheet metal? Understanding the diversity of bending techniques can significantly enhance your product’s precision and performance.

As an expert in the metal fabrication industry, I’ve seen firsthand how the right bending type can transform a project. I’m here to share insights that can help optimize your operations and ensure you’re using the most efficient and effective methods.

Here is a sneak peek at the top 2 bending types that we’ll delve into:

- Air Bending

- Bottoming

In this guide, you’ll learn about the 10 essential types of bending used in sheet metal fabrication. From understanding each method’s mechanics to knowing when to apply them for maximum efficiency, we’ve covered it all.

Read on to elevate your metal fabrication game.

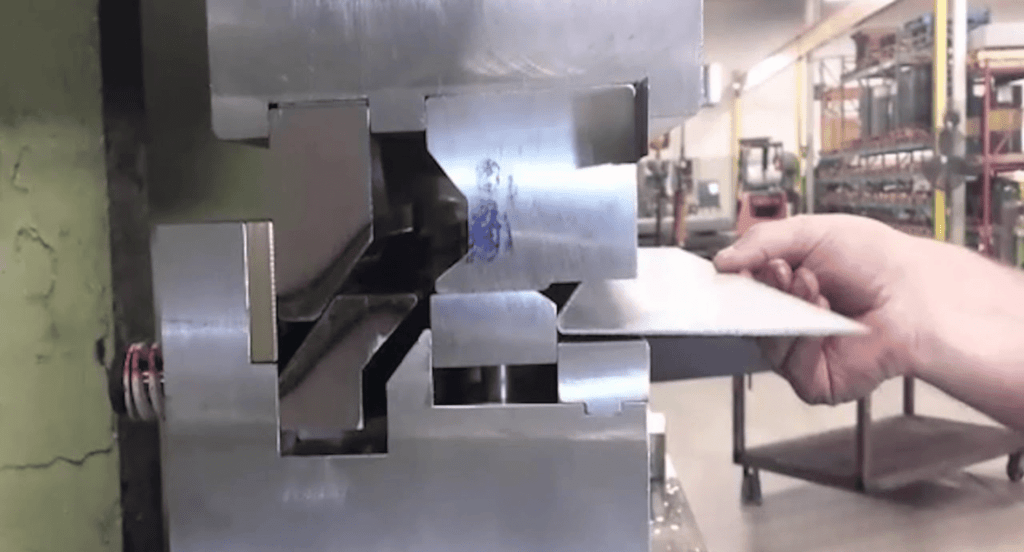

1. Air Bending

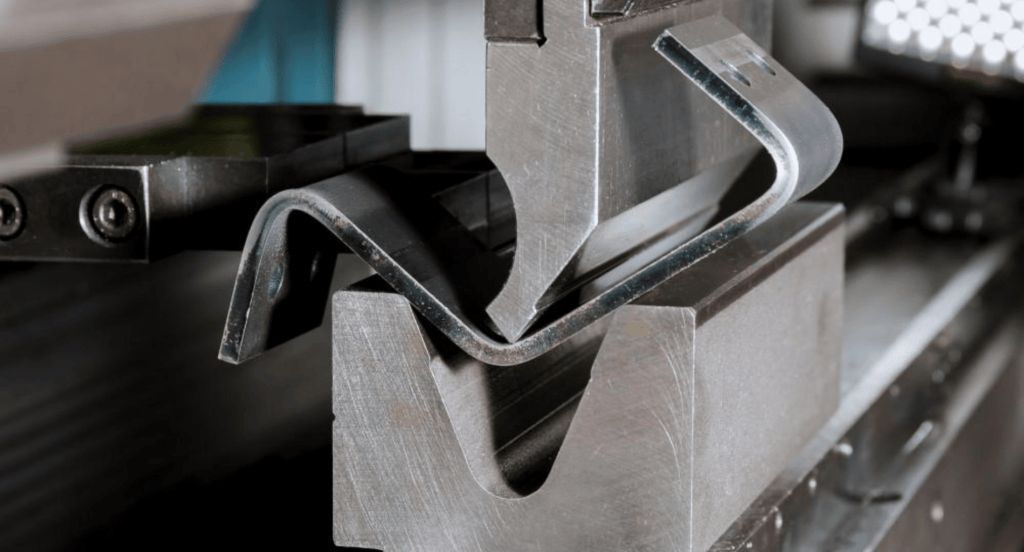

Air bending is a technique in sheet metal fabrication where the material is pressed between a punch and a die. Unlike other bending methods, the sheet does not touch the die’s bottom, and the bend is formed by the punch forcing the metal down into a V-shaped die. This method is highly versatile and allows for a wide range of bend angles with one tool.

Features

- Controlled Deformation: Air bending allows for precise control over the angle and depth of the bend. The sheet metal doesn’t fully conform to the die shape, which means the angle can be adjusted without changing tools.

- Tool Longevity: Since the metal doesn’t come into full contact with the die, there’s less wear on the tools. This means longer tool life and lower maintenance costs.

- Flexibility: One set of tools can create a variety of bend angles. This flexibility makes air bending a cost-effective and time-efficient choice for various projects.

Common Applications

- Aerospace Industry: Air bending’s precision is crucial for the aerospace sector, where components must meet strict standards. The method’s ability to produce consistent, accurate bends makes it a staple in this field.

- Automotive Manufacturing: The automotive industry benefits from air bending’s flexibility and speed, using it to shape body panels, frames, and other components efficiently.

- Construction: In construction, air bending is used to create custom metal components like beams, frames, and supports. Its adaptability allows for on-the-spot adjustments, making it ideal for custom projects.

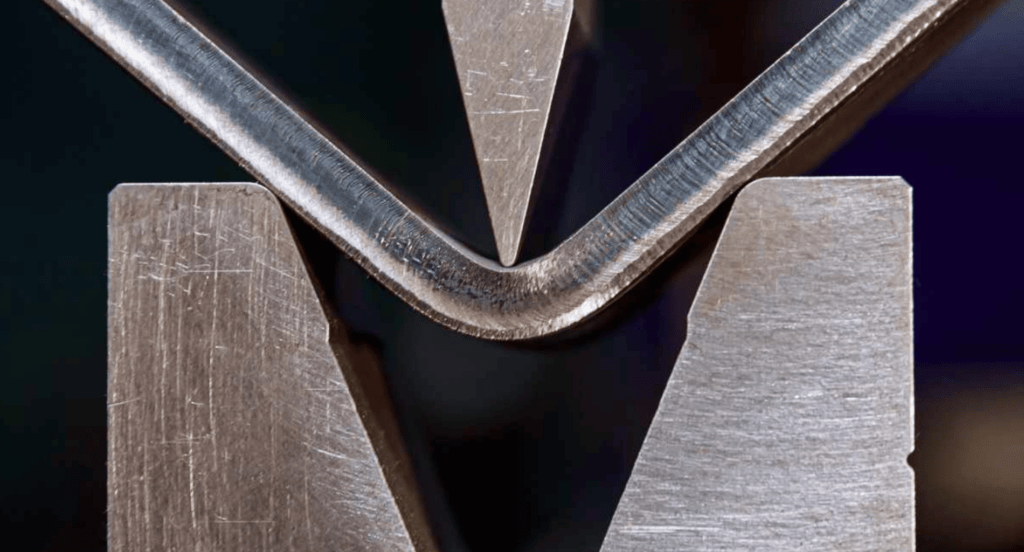

2. Bottoming

Bottoming, also known as ‘V-die bending,’ is a precise sheet metal fabrication method where the material is pressed into a die until it bottoms out. Unlike air bending, the sheet is forced to conform to the die’s angle, resulting in a more accurate bend. This technique is especially beneficial when seeking uniformity and sharp angles in the final product.

Features

- High Precision: Bottoming provides a high level of precision and repeatability. Since the metal is forced to conform to the die’s shape, the resulting angles are consistent and accurate.

- Reduced Springback: One of the key advantages of bottoming is the minimal springback compared to other methods.This is particularly useful when working with materials known for their tendency to spring back.

- Sharp Angles: Bottoming is ideal for creating sharp, defined angles. The nature of the process allows for crisp bends, essential for complex designs and tight specifications.

Common Applications

- Electronics Manufacturing: In the electronics industry, where components must be precise and consistent, bottoming is often used to create casings, brackets, and other parts with sharp, defined angles.

- Architectural Metalwork: Bottoming is used in architectural metalwork to create detailed, precise components. Its ability to produce sharp angles and clean lines is essential for aesthetic and functional elements.

- Automotive Parts: Bottoming is used in the automotive industry for parts that require uniformity and precision. The method’s ability to create consistent bends ensures that parts fit together perfectly during assembly.

3. Folding

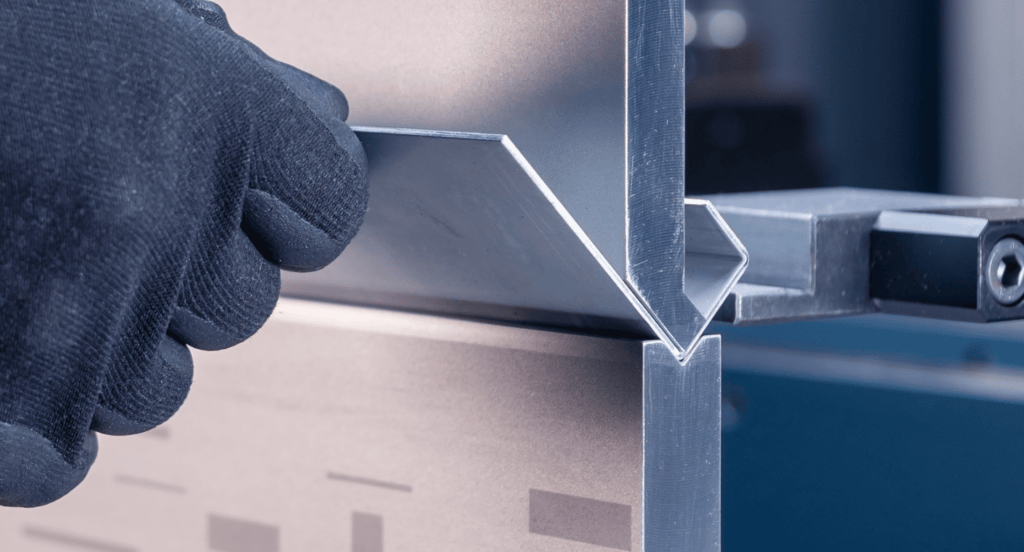

Folding in sheet metal fabrication is a process where the material is clamped and then bent over a straight edge or a line. This method doesn’t rely on traditional dies, like in air bending or bottoming, but uses a folding beam to achieve the bend. Folding is particularly advantageous for delicate or large pieces where traditional methods might be impractical.

Features

- Versatility: Folding can handle large and delicate pieces that might be difficult to work with using other bending methods. It allows for a wide range of shapes and sizes, offering flexibility in design and production.

- Precision: As the metal is clamped down before bending, folding offers high precision. This controlled process results in consistent, accurate bends.

- Gentle Handling: The gentle nature of the folding process means less risk of damaging the material. This is especially beneficial when working with pre-finished or sensitive materials.

Common Applications

- Architectural Panels: In the architectural industry, folding is often used to create large, precise panels and facades. The method’s ability to handle large sizes makes it ideal for building applications.

- Signage and Displays: Folding is used in creating signs and displays that require precise angles and gentle handling, especially when dealing with pre-painted or coated materials.

- Aerospace Components: The aerospace industry utilizes folding for various components where precision and handling are paramount. The method’s gentle approach and accuracy are essential for the high standards required in this field.

4. Rotary Bending

Rotary bending is a modern sheet metal fabrication technique where the material is formed around a rotating cylinder or bending die. This method allows for high-speed bending without the risk of marring the material’s surface, as there’s minimal contact during the process. This type is known for its speed and ability to produce clean, sharp bends with a minimal risk of deformation.

Features

- Surface Integrity: One of the standout features of rotary bending is its ability to maintain the surface integrity of the material. Since contact is minimal and there’s no direct clamping on the sheet, the risk of scratches or marks is significantly reduced.

- Speed: Rotary bending is designed for speed. The rapid rotation and efficiency of the process make it ideal for high-volume production runs where time is of the essence.

- Complex Bends: This method allows for complex bending operations, including tight radius bends and multiple bends in close succession. The versatility in the type of bends achievable makes it suitable for intricate designs.

Common Applications:

- Automotive Industry: Rotary bending is extensively used in the automotive sector for parts that require precise, clean bends, such as trim pieces, brackets, and panels. The method’s speed aligns well with the industry’s high-volume production demands.

- Appliance Manufacturing: In appliance manufacturing, where surface finish is critical, rotary bending is a preferred method. For instance, it is commonly used for components like panels and frames that require an impeccable finish.

- Electronic Enclosures: The electronics industry often uses rotary bending to create enclosures and casings. The precision and ability to maintain surface finish are crucial for the aesthetic and functional requirements of electronic components.

5. Wipe Bending

Wipe bending, also known as edge bending, involves pressing the sheet metal over a die edge to create a bend. In this method, the workpiece is clamped and then bent over a straight edge or die by a wiping tool. This technique is particularly useful for creating bends with a larger radius and is often employed when more conventional bending methods might not be suitable.

Features

- Large Radius Bends: Wipe bending is particularly well-suited for creating larger radius bends that might be challenging with other methods. This feature makes it versatile for various design requirements.

- Simplicity: The process is relatively simple and doesn’t require the complex machinery associated with some other bending techniques. This simplicity can translate into cost savings and ease of operation.

- Surface Contact: During wipe bending, the wiping tool makes continuous contact with the material. This can be beneficial for certain materials and applications, though it also means the surface finish needs to be considered carefully.

Common Applications

- Construction Industry: In construction, wipe bending is often used for creating metal framing and structural components that require larger radius bends. Its ability to handle bigger pieces makes it a practical choice for this sector.

- HVAC Systems: According to Technavio, HVAC market will grow upto $74.02 billion by 2028, the role of wipe bending in fabricating ductwork and other components becomes increasingly significant. This method is essential for creating larger, gentle bends necessary for functionality in HVAC systems, aligning with the industry’s expanding needs and technological advancements.

- Furniture Manufacturing: The furniture industry sometimes employs wipe bending for creating metal frames and decorative elements. The ability to produce smooth, large-radius bends is particularly useful for aesthetic purposes in this industry.

6. V-Bending

V-bending is a common sheet metal fabrication technique where the material is bent by being pressed into a V-shaped die. This method utilizes a punch with a corresponding shape that forces the metal into the die, creating the bend. V-bending can be further categorized into air, bottoming, and coining, each varying in the degree of contact and pressure applied.

Features

- Versatility: V-bending is suitable for a wide range of materials and thicknesses, making it one of the most versatile bending techniques. This adaptability makes it a go-to choice for many fabricators.

- Precision: With the right setup, V-bending can achieve a high degree of precision and repeatability. The distinct shape of the die and punch ensures that each bend is consistent.

- Efficiency: V-bending is known for its efficiency, especially in high-volume production. The simplicity of the process allows for quick setup and operation, leading to faster turnaround times.

Common Applications

- Metal Furniture Production: In the furniture industry, V-bending is often used to create frames and structural elements. Its ability to produce precise and clean bends makes it ideal for aesthetic and functional pieces.

- Automotive Components: The automotive industry relies on V-bending for various parts, from body panels to structural elements. The technique’s precision and efficiency are key for meeting the industry’s high standards and production demands.

- Construction Materials: V-bending is commonly used in the construction of metal roofing, siding, and framing components. Its ability to handle a range of material types and thicknesses makes it a valuable tool for this industry.

7. U-Bending

U-bending is a specific type of sheet metal fabrication process where the material is shaped into a U form. This is achieved by pressing the metal between a punch and a U-shaped die, which together bend the material into the desired shape. U-bending is distinct for its ability to create uniform U-shaped profiles, which are crucial in various applications.

Features

- Uniformity: U-bending is renowned for producing consistent and uniform U-shaped bends. The precision of the die ensures that each bend is identical, which is vital for parts that require symmetry.

- Efficiency: This method is efficient for producing multiple identical U-shaped bends. The simplicity of the process allows for rapid production without sacrificing quality.

- Strength Enhancement: U-bending can enhance the strength and rigidity of the material. The U shape adds structural integrity, making the final product more robust and resistant to deformation.

Common Applications

- Piping and Tubing: In industries like plumbing and HVAC, U-bending is used to create pipes and tubes that require precise U-shapes for installation and function. The uniformity and accuracy are essential for ensuring that systems fit together seamlessly and operate correctly.

- Automotive Manufacturing: U-bending is used in the automotive industry for parts like brackets, frames, and supports. The strength and precision provided by U-bending are crucial for the durability and performance of these components.

- Furniture and Fixture Production: U-bending is often employed in the production of metal furniture and fixtures. The process’s ability to create strong, uniform U-shapes is ideal for frames, legs, and supports that are both functional and aesthetically pleasing.

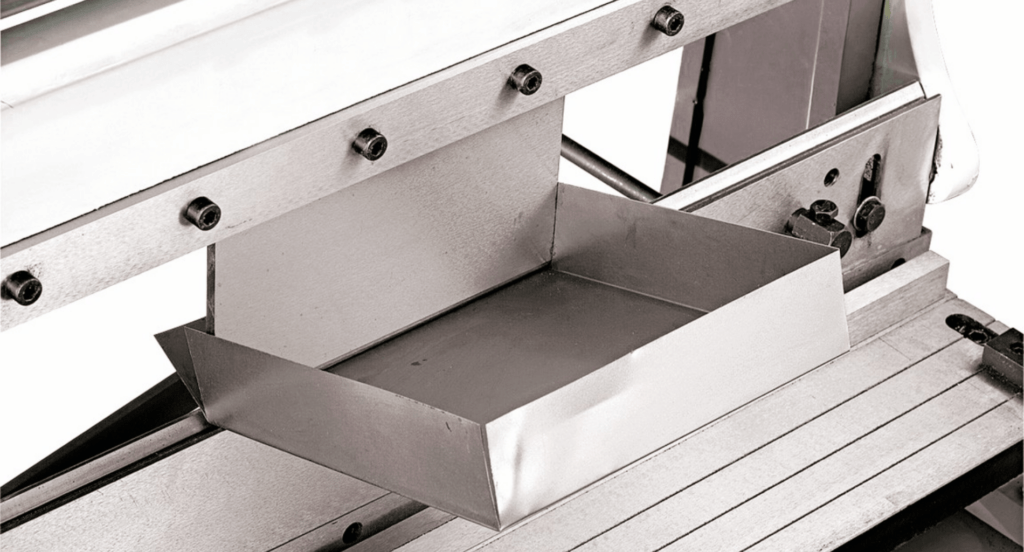

8. Step Bending

Step bending is a method used in sheet metal fabrication to create consecutive bends in a piece, forming a step-like pattern. This technique involves making a series of incremental bends along the length of the material, each at a different angle or position to achieve the desired profile. Step bending is particularly useful for forming complex, multi-angular shapes with precision.

Features

- Complex Shapes: Step bending excels in creating intricate designs and complex shapes that other bending methods can’t achieve. It allows for a high degree of customization in the design of the metal piece.

- Precision: The method offers precise control over the bend angles and distances between them. This precision is crucial for components that must fit together perfectly or meet strict specifications.

- Flexibility: Step bending is flexible in terms of the types of bends it can produce. Whether you need sharp angles, shallow curves, or a combination of both, step bending can accommodate. Zemetal utilizes this versatility of step bending to meet diverse client specifications in their metal fabrication projects.

Common Applications

- Architectural Elements: In architecture, step bending is used to create complex, decorative elements and functional components like stair railings and trim. The ability to produce unique, custom shapes is particularly valued in this industry.

- Aerospace Components: The aerospace industry relies on step bending for parts that require complex shapes and precise dimensions, such as brackets and paneling. The method’s precision and versatility make it a good fit for the sector’s strict requirements.

- Electronics Housings: Step bending is used in electronics manufacturing to create housings and enclosures with multiple bends. This allows for the design of compact, custom-shaped components that fit specific devices or spaces.

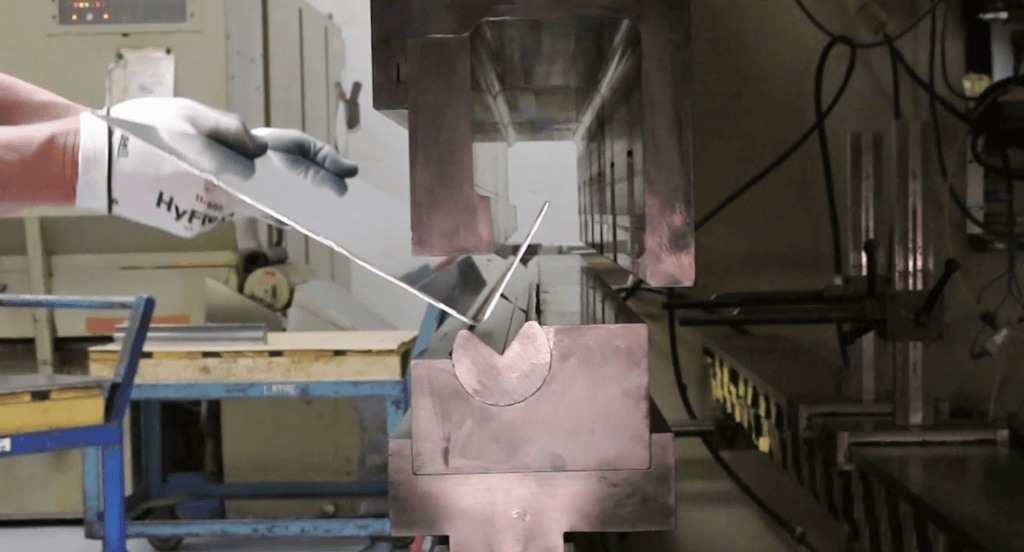

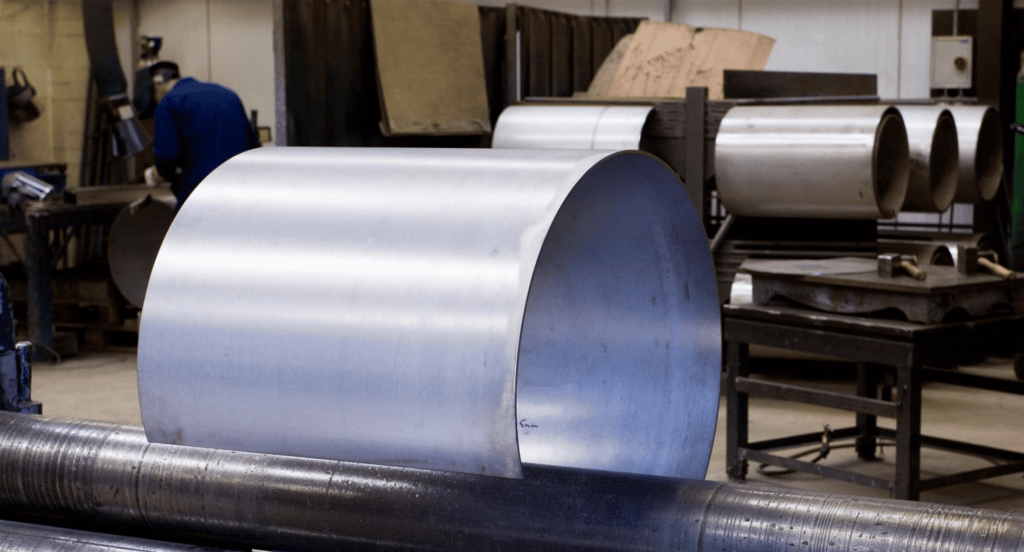

9. Roll Bending

Roll bending is a process in sheet metal fabrication where metal is passed through a series of rolls to gradually achieve a curved or radius form. This technique uses two or more rollers to apply continuous bending action, creating cylindrical or conical shapes. Roll bending is particularly effective for producing large, smooth curves without seams or joints.

Features

- Large Radius Curves: Roll bending excels at creating large, sweeping curves that are smooth and consistent. For example, in creating the curved beams for train station’s roof, roll bending ensures a uniform curvature essential for the structural integrity of the design. This feature is ideal for components that require a gentle, continuous bend.

- Efficiency for Long Pieces: The process is particularly efficient for bending long pieces of metal. As the material is fed through the rolls, continuous bending can be achieved quickly and uniformly.

- Versatility in Shape: Roll bending can produce various shapes, including cylindrical, conical, or complex curves. This versatility makes it suitable for a wide range of applications and designs.

Common Applications

- Construction and Structural Components: In the construction industry, roll bending is used for creating curved beams, arches, and frames. The ability to produce large, smooth curves is essential for both the aesthetic and structural elements of buildings.

- Shipbuilding: The shipbuilding industry relies on roll bending to shape the metal hulls and structural elements of vessels. The technique’s ability to handle large, long pieces of metal is particularly beneficial in this field.

- Decorative Metalwork: Roll bending is often used in creating decorative metal art, signage, and furniture. The smooth curves and shapes achievable through roll bending contribute to the aesthetic appeal of these items.

10. Elastomer Bending

Elastomer bending is a unique sheet metal fabrication process that uses an elastomeric pad as the die in a press to form the metal. This method allows for bending without traditional hard tooling, using the flexible nature of the elastomer to create the bend. Elastomer bending is particularly useful for low-volume production where cost savings of avoiding dedicated dies are beneficial.

Features

- Reduced Tooling Costs: One of the most significant advantages of elastomer bending is the reduced need for specific tooling. The elastomeric pad can conform to various shapes and sizes, eliminating the need for multiple hard dies. Zemetal leverages this flexibility of elastomer bending to minimize tooling costs in their metal fabrication projects.

- Flexibility in Design: Elastomer bending allows for a high degree of design flexibility. The method can accommodate complex, asymmetrical, or unique bends that might be challenging with traditional methods.

- Surface Finish Preservation: As the metal is pressed against a soft elastomer rather than a hard die, the risk of marring or scratching the surface is significantly reduced. This is particularly beneficial when working with pre-finished or sensitive materials.

This table outlines the advantages of using a soft elastomer in metal pressing to preserve the surface finish, especially beneficial for delicate or pre-finished materials.

| Advantage | Description | Impact on Metal Finishing |

| Reduced Risk of Marring | Minimizes surface damage during pressing | Ensures integrity of the final product |

| Lowered Scratching Probability | Less abrasive than hard dies | Preserves aesthetic quality |

| Suitability for Pre-Finished Materials | Ideal for materials that require minimal alteration | Enhances end-product quality |

| Enhanced Protection for Sensitive Materials | Gentle approach maintains material properties | Critical for high-quality applications |

| Improved Final Aesthetics | Results in a cleaner, more polished finish | Increases market appeal of finished goods |

Common Applications

- Aerospace Industry: Elastomer bending is used in aerospace for prototyping or low-volume production of components with unique or complex shapes. The method’s ability to create precise, custom shapes without extensive tooling is highly valued.

- Automotive Prototyping: In the automotive industry, elastomer bending is often used for prototyping new parts. The flexibility and cost-effectiveness of the process make it ideal for experimenting with different designs and shapes.

- Custom Metal Fabrication: For custom metal fabrication, including art installations or unique architectural elements, elastomer bending provides a versatile solution. It allows for the creation of one-of-a-kind pieces without the need for expensive custom dies.

Conclusion

Understanding the various bending methods in sheet metal fabrication is crucial for optimizing your production and achieving the best results. This guide has illuminated 10 essential techniques, helping you make informed decisions for your projects.

If you’re seeking to delve deeper into these bending processes and discover how they can elevate your operations, Zemetal is here to assist. Contact us today for further consultation.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.