Have you considered how silk screen printing could enhance your metal product offerings? Dive into the world of the silk screen printing business, where innovation meets practicality.

With years of expertise in this field, our insights offer a valuable perspective, guiding you through the details and rewards of silk screen printing.

In the diverse landscape of modern industry, silk screen printing stands out as a creative and practical way to customize metal and enhance branding. It transforms visual communication and design, setting a fresh standard in the industry.

In this guide, we will navigate through the essentials of silk screen printing, examining its impact on product enhancement and business growth.

Read on to uncover valuable insights.

1. Understanding Silk Screen Printing

Silk screen printing, a technique traditionally associated with textiles and paper, has found a significant place in metal fabrication. This process involves transferring designs onto surfaces, offering a durable and precise method for branding and decorating products. It’s particularly valuable for creating high-quality, detailed designs on metal components, elevating both their aesthetic and functional appeal.

The adaptability of silk screen printing in metal fabrication lies in its ability to handle various metal types, including aluminum, stainless steel, and brass. This method is ideal for producing everything from industrial labels and signage to decorative panels and equipment interfaces. Its integration into metal fabrication signifies a blend of art and industry, opening new possibilities for product customization and branding.

2. The Business Benefits of Silk Screen Printing

After understanding silk screen printing, it’s important to explore how this technique can be a game-changer for businesses with various benefits it offers. Here are its key advantages:

- Cost-Effectiveness: Silk screen printing is a cost-effective choice, particularly for big production runs. While the setup cost might seem high at first, it becomes budget-friendly when printing in large quantities. This makes it an appealing choice for businesses aiming to create many prints without sacrificing quality.

- Versatility in Materials and Designs: This technique is highly versatile, accommodating various metals and designs, enabling to offer a wide range of customized and detailed designs on products. This flexibility enhances the appeal and marketability of items, from industrial parts to decorative pieces.

- Scalability for Large Orders: For businesses handling large-scale metal fabrication projects, silk screen printing offers unmatched scalability. It simplifies the production process, allowing for consistent quality across extensive batches, which is essential for meeting the demands of large industrial clients efficiently.

- High-Quality and Durable Outputs: Silk screen printing offers high-quality, durable, fade-resistant results, crucial for products exposed to harsh environments. This durability is a significant selling point for clients seeking long-lasting metal products.

3. Essential Equipment for a Silk Screen Printing Business

Transitioning from the benefits of silk screen printing, the focus shifts to the equipment used that contribute to the efficiency and profitability of a silk screen printing business. Here are the key pieces of equipment:

Screen Printing Press

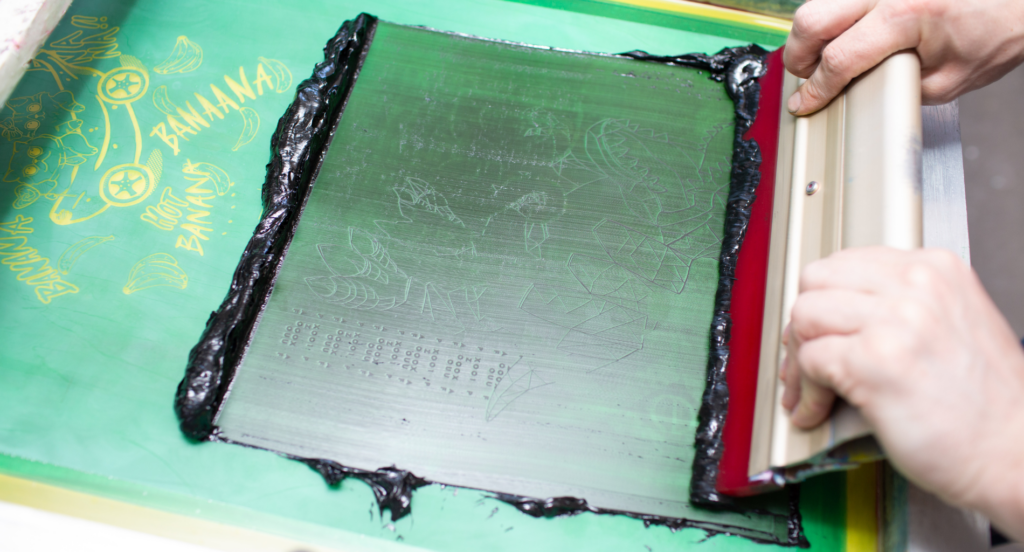

The screen printing press is crucial for applying designs onto metal. It allows for precise control over the placement and pressure of the print, ensuring consistent quality. This equipment is especially useful in creating detailed and complex designs on metal sheets or components.

Conveyor Dryers

Conveyor dryers are used to quickly and evenly dry ink on metal products. They ensure the ink is properly cured, which is essential for durability and longevity, especially on metal surfaces that may be exposed to harsh conditions. As per Data Intelo, the conveyor dryers market is set to grow at a 5.5% CAGR between 2022 and 2030, driven by rising demand from industries such as garments, textiles, and printing.

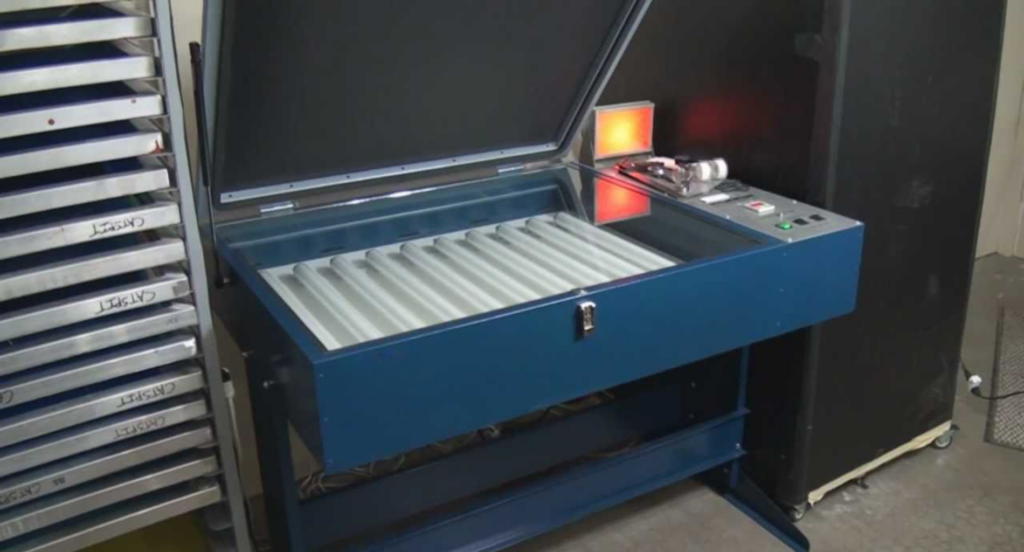

Exposure Units

Exposure units are used to transfer designs onto screens before printing on metal. They play a critical role in defining the sharpness and accuracy of the image, which is especially important for detailed metalwork. This equipment ensures that every detail of the design is perfectly captured for high-quality printing.

Screen Printing Inks

Screen printing inks for metal fabrication are formulated to stick strongly to metal surfaces. These inks are designed to resist fading, chipping, and wear, maintaining the vibrancy and integrity of the print on metal products. Choosing the right ink is essential for ensuring that prints can withstand the specific challenges of metal surfaces.

4. Strategic Marketing for Silk Screen Printing Businesses

Having equipped with the essential equipment, it’s time to strategize the market approach of the business to have a higher chance of success. Here are some strategic marketing to take note of:

Online Marketing and Social Media

In today’s digital age, an effective online presence is crucial for silk screen printing businesses. Utilizing social media platforms can showcase the prints and attract a niche audience. Engaging content about metal fabrication projects helps build brand awareness and connect with potential clients.

Networking and Industry Partnerships

Forming partnerships within the metal fabrication industry can open doors to new opportunities and markets for the silk screen printing business. Networking with metal suppliers, fabricators, and distributors can lead to mutually beneficial collaborations. These relationships are essential for understanding market needs and staying ahead of industry trends.

Trade Shows and Exhibitions

Participating in trade shows and exhibitions is a strategic way to showcase the silk screen printing capabilities. These events are perfect for demonstrating the versatility and quality of prints to a targeted audience. They also provide an opportunity to connect with industry peers and potential clients.

Customer Testimonials and Word-of-Mouth

Positive feedback from satisfied clients in the metal industry can be a powerful marketing tool for the silk screen printing business. Sharing customer testimonials, especially those related to metal fabrication projects, helps build trust and credibility. Encourage clients to share their experiences, which can effectively attract new business through word-of-mouth.

5. Challenges and Solutions in the Silk Screen Printing Business

Once solid marketing strategy is established, understanding challenges in silk screen printing is crucial to significantly enhance operation. Here are the key challenges together with their practical solutions:

Managing Supply Chain and Inventory

A major challenge in silk screen printing is ensuring a steady supply of materials such as specific inks for metals. To overcome this, businesses can establish strong relationships with multiple suppliers to ensure a consistent inventory. Additionally, implementing an efficient inventory management system can help track and manage stock levels effectively.

Quality Control and Consistency

Achieving consistent quality is challenging when printing on varied metal surfaces. To address this issue effectively, consider regularly training the staff in metal-specific printing techniques and ensuring the precise calibration of the printing equipment. Establishing strict quality control checks ensures each print meets the industry standards required in metal fabrication.

Environmental and Safety Regulations

Silk screen printing on metal often involves the use of chemicals and materials that are subject to environmental and safety regulations. To address this, businesses should adopt eco-friendly practices and ensure proper handling and disposal of hazardous materials. Regular training on safety protocols and compliance with environmental standards can reduce these risks.

Technological Upgrades and Training

Keeping up with technological advancements is crucial, yet challenging, in silk screen printing. Investing in the latest printing technology suitable for metals can significantly improve efficiency and quality. Providing ongoing training for employees ensures they are skilled at using new equipment and techniques. Zemetal continuously incorporate advanced technology and training, demonstrating a commitment to innovation and efficiency.

Competitive Pricing and Market Positioning

Maintaining competitive pricing while offering high-quality prints can be difficult. A solution is to balance cost-effective production methods without compromising on quality. Effectively communicating the unique benefits of silk screen printing on metal helps in strategic market positioning and attracting a specific clientele.

6. Trends and Opportunities in Silk Screen Printing Business

Building on the challenges and solutions identified in silk screen printing, it’s time to dive into the emerging trends and opportunities that are shaping the future of the business. Here are some key areas to watch:

Eco-Friendly and Sustainable Practices

The shift towards sustainable practices in silk screen printing is increasingly relevant. Using eco-friendly inks and recycling metal materials reduces environmental impact. This trend not only aligns with global sustainability goals but also appeals to environmentally conscious clients.

Integration of Digital Technologies

Digital technology integration is transforming silk screen printing. Advanced digital printers allow for more precise and detailed designs on metal surfaces. For example, adoption of UV flatbed printers, which are capable of printing directly onto metal sheets, offering exceptional detail and color accuracy. This technological advancement enables businesses to offer unique, high-quality products and attract a broader range of clients.

Collaboration with Designers and Artists

Collaborating with designers and artists opens new avenues in silk screen printing on metal. These collaborations can result in innovative and artistic metal prints, expanding the market reach. Such partnerships often lead to unique products that stand out in both the art and industrial sectors.

Expansion into New Markets

Exploring new markets, such as architectural metalwork or automotive parts, provides growth opportunities for silk screen printing businesses. Applying silk screen printing techniques to metal components in various sectors can diversify business offerings. This expansion can lead to increased income opportunities and a stronger market position.

This table outlines key aspects and potential benefits of silk screen printing businesses expanding into new markets like architectural metalwork and automotive parts.

| Market Expansion Area | Benefits | Potential Impact on Business |

| Architectural Metalwork | Customization in design and aesthetics | Attracts a new customer base and projects |

| Automotive Parts | Durable and high-quality printing for parts | Opens revenue streams in the automotive industry |

| Industrial Equipment | Enhanced branding and labeling capabilities | Expands into high-demand industrial sectors |

| Consumer Electronics | Precision and versatility in small-scale items | Engages with a rapidly evolving tech market |

| Sporting Goods | Unique, durable designs for equipment | Taps into a diverse and active consumer market |

7. 5 Factors to Consider When Starting a Silk Screen Printing Business

As the silk screen printing industry evolves with new trends and opportunities, it’s crucial for businesses to consider key factors before diving into this dynamic business. Here are the essential elements to focus on:

#1 Market Analysis and Target Audience

Before starting a silk screen printing business, it’s crucial to conduct a thorough market analysis. Understanding the demand for printed metal products helps in targeting the right audience. Tailoring services to meet the specific needs of industries that heavily use metal, such as automotive or construction, can create a niche market.

#2 Capital Investment and Budgeting

Setting up a silk screen printing business requires significant capital investment in specialized machinery and materials. For example, allocating funds for advanced screen printing presses and metal-compatible inks is essential for high-quality metal printing. It’s also important to consider the ongoing costs of maintenance and supplies to ensure long-term financial sustainability.

#3 Location and Infrastructure

The location for a silk screen printing business should be strategically chosen. A site close to industrial centers can reduce logistics costs and improve client relations. The infrastructure must support heavy equipment and provide adequate space for the handling and storage of metal materials.

#4 Skilled Workforce and Training

Employing a skilled workforce is vital for a business specializing in silk screen printing. Staff should be trained in specific techniques for printing on metal surfaces to ensure high-quality results. Continuous training is necessary to keep up with advancements in metal printing technologies. Zemetal continuously invests in training programs, keeping the team updated with the latest advancements in metal printing technologies.

#5 Legal Requirements and Compliance

Complying with legal requirements is critical. This includes obtaining the necessary permits for handling and disposing of metal waste and solvents. Ensuring compliance with health and safety regulations to protect workers handling metal materials is also essential.

Conclusion

Navigating through the silk screen printing industry requires both creative insight and practical expertise. This guide serves as a valuable resource, offering knowledge and strategies to improve operational efficiency, expand market reach, and encourage innovation in your business endeavors.

If you are seeking to incorporate advanced silk screen printing into your metalwork, Zemetal is ready to assist. Reach out to us for customized solutions that can redefine your product offerings.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.