Is silk screen printing the right choice for your business? Understanding its advantages and disadvantages is key to making informed decisions in the competitive field of metal fabrication.

With years of experience in the metal fabrication industry, I bring a depth of knowledge that can help you navigate the complexities of silk screen printing.

Silk screen printing offers a mix of benefits and challenges. The versatility and efficiency of this method are balanced by considerations unique to the specific needs of each business.

In this guide, we’ll explore the details of silk screen printing, providing you with a comprehensive understanding of its impact on your business.

Read on for key insights into silk screen printing.

1. Overview of Silk Screen Printing

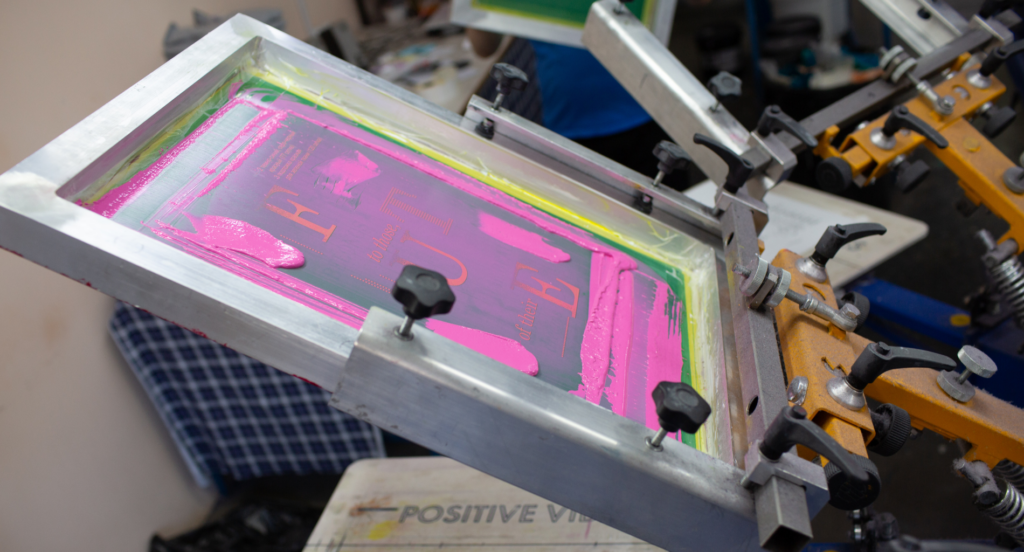

Silk screen printing is a distinguished method in metal fabrication, prized for its precision and ability to produce vivid, enduring results. In this process, a stencil design is transferred onto a metal surface using a mesh screen and specialized inks. It’s particularly effective for large-scale productions where consistency and quality are paramount.

The adaptability of silk screen printing to various design complexities has always stood out, offering a reliable solution for intricate and high-volume projects. This technique represents perfect artistry and industrial efficiency, making it a go-to choice for many businesses.

2. Advantages of Silk Screen Printing

Following the comprehensive overview of silk screen printing, it’s clear why this technique is highly regarded in the industry. Let’s explore the key advantages that set silk screen printing apart from other methods:

Durability and Quality

Silk screen printing excels in providing durable and high-quality results. The technique involves ink that penetrates deeply into the material, ensuring prints that are resistant to fading, peeling, and environmental wear. This resilience is especially beneficial in the metal fabrication industry, where longevity and robustness are key.

Versatility in Design

The versatility of silk screen printing is a standout feature, accommodating a broad spectrum of designs from simple text to complex imagery. This adaptability is crucial in metal fabrication, allowing for a wide range of creative applications. Zemetal utilizes silk screen printing to cater to diverse client demands, from intricate details artistic patterns to bold industrial markings.

Cost-Effectiveness for Large Batches

One significant advantage of silk screen printing is its cost-effectiveness, especially for large orders. Once the initial setup is complete, the cost per unit becomes increasingly economical. For example, a large order of custom metal panels with a company logo can be produced at a lower cost per item, without compromising on quality.

3. Disadvantages of Silk Screen Printing

Having discussed the significant advantages of silk screen printing, it’s essential to also address its drawbacks. Understanding these limitations is key to making informed decisions in the printing process. Let’s take a closer look at the challenges associated with this technique:

Restricted Detail Accuracy

Silk screen printing may not be the best choice for designs requiring extremely high detail. The nature of the screen can limit the resolution of finer details, which can be a concern for projects demanding intricate patterns. For example, replicating a highly detailed image on a small metal part might result in a loss of clarity, thus affecting the overall aesthetic.

Environmental Concerns

Silk screen printing involves the use of certain chemicals and inks that can raise environmental concerns. The disposal of these materials and the cleaning process can impact the environment if not managed properly. This factor is increasingly important for businesses striving to maintain eco-friendly practices and comply with environmental regulations.

High Initial Setup Cost

Silk screen printing requires a considerable initial investment in terms of equipment and setup. This includes the cost of screens, inks, and other materials. For small businesses or those with limited budgets, this initial outlay can be a significant barrier, making it less feasible for short runs or limited edition projects.

4. 3 Factors to Consider Before Implementing Silk Screen Printing

In light of the disadvantages of silk screen printing, it is crucial for businesses to carefully evaluate several factors before adopting this method. Here are specific considerations to keep in mind:

#1 Quality Expectations

Assessing quality expectations is critical. Silk screen printing offers a specific quality level, particularly suitable for bold and less intricate designs. It’s important to match the project’s quality requirements with the capabilities of silk screen printing, considering factors like resolution, color fidelity, and finish. If a project demands ultra-high resolution or precise color gradients, alternative methods might be more appropriate.

#2 Color Requirements

In planning for silk screen printing, it’s essential to carefully consider color requirements. Projects requiring specific shades often rely on U.V. cured inks for their unmatched color precision and consistency. Industryarc’s projection that the UV curing ink resins market will grow to US$2.2 billion by 2027 reflects their critical role in printing. These resins, with their unique benefits, are crucial for accurately replicating designs in the final print.

This table outlines the key aspects of color requirements in silk screen printing, emphasizing the role of U.V. cured inks and their impact on design replication and market growth.

| Factor | Description | Relevance to Silk Screen Printing |

| Color Precision | U.V. cured inks offer unmatched color accuracy | Crucial for specific shade replication |

| Consistency | Ensures uniform color in all prints | Vital for large-scale production quality |

| Market Projection | Industryarc forecasts significant growth by 2027 | Indicates increasing demand and usage |

#3 Turnaround Time and Efficiency

Turnaround time and efficiency are significant factors, particularly for time-sensitive projects. Silk screen printing can be time-consuming, especially when dealing with complex designs or large quantities. Businesses must weigh their timeline against silk screen printing’s efficiency for their project needs. At Zemetal they emphasize efficient production processes to meet client deadline without compromising on quality.

Conclusion

Silk screen printing offers a unique combination of advantages and challenges, making it an essential consideration for metal fabrication projects. This guide aims to provide a comprehensive understanding, helping businesses make informed decisions.

For those seeking expert guidance in silk screen printing and metal fabrication, Zemetal stands ready to assist. Contact us to discuss your needs and how we can help bring your vision to reality.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.