Ever had trouble finding the right sheet metal fabricator in the UK? Choosing the right partner can make a big difference in finishing your projects on time and within budget.

As a Production Planner with experience in sheet metal fabrication, I’ve worked with many manufacturers and know what makes a great one. My knowledge comes from years of managing production and large projects.

Whether you need accuracy, speed, or custom fabrication, here are the top 6 sheet metal fabricators in the UK that can meet your business’s unique needs.

In this review, I’ll break down what makes each of these fabricators a strong option. You’ll learn about their capabilities, specializations, and why they should be on your radar for your next project.

Let’s jump right in!

1. Alpha Manufacturing – Best in High-Volume Metal Components

City & Country: Hixon Staffordshire, United Kingdom

Established: 1989

Alpha Manufacturing leads the sub-contract sheet metal fabrication industry, supplying high-volume metal components to top UK companies across automotive, retail, electronics, agriculture, and technology sectors. Their expertise encompasses a full range of fabrication services, including comprehensive metal design and engineering, nationwide delivery of finished products, and quick-turnaround prototyping. –

Key Services: Their main services include Stainless Steel Fabrication and CNC Punch. Stainless Steel Fabrication creates durable and corrosion-resistant metal components for various industries. CNC Punch provides precision punching, enabling accurate holes and shapes in stainless steel for efficient manufacturing.

Takeaway Note:

Alpha Manufacturing excels in delivering high-volume orders with remarkable efficiency and precision. However, smaller entities or those seeking more personalized service might find Alpha’s large-scale production focus less accommodating to their specific needs.

2. JC Metalworks – Best in Retail Display Manufacturing

City & Country: Leicestershire, United Kingdom

Established: 1986

JC Metalworks specializes in crafting bespoke retail displays, fixtures, and fittings for well-known retail brands. Their Retail Division excels in producing a diverse range of shop fitting and display items. They have established a reputation for excellence in retail display manufacturing, combining expertise in metal fabrication and welding to meet complex client demands.

Key Services: Their main services include Metal Fabrication and Welding. Metal Fabrication involves cutting, bending, and assembling metal parts to create custom structures. Welding ensures secure and strong joints between these metal components, providing structural integrity to the final product.

Takeaway Note:

JC Metalworks is a top choice for retailers seeking high-quality, customized display solutions. However, businesses looking for standard, off-the-shelf solutions may find JC Metalworks’ focus on custom-made items less suited to their immediate needs.

3. Get It Made – Best in Custom Metal Fabrication Solutions

City & Country: London, United Kingdom

Established: 2011

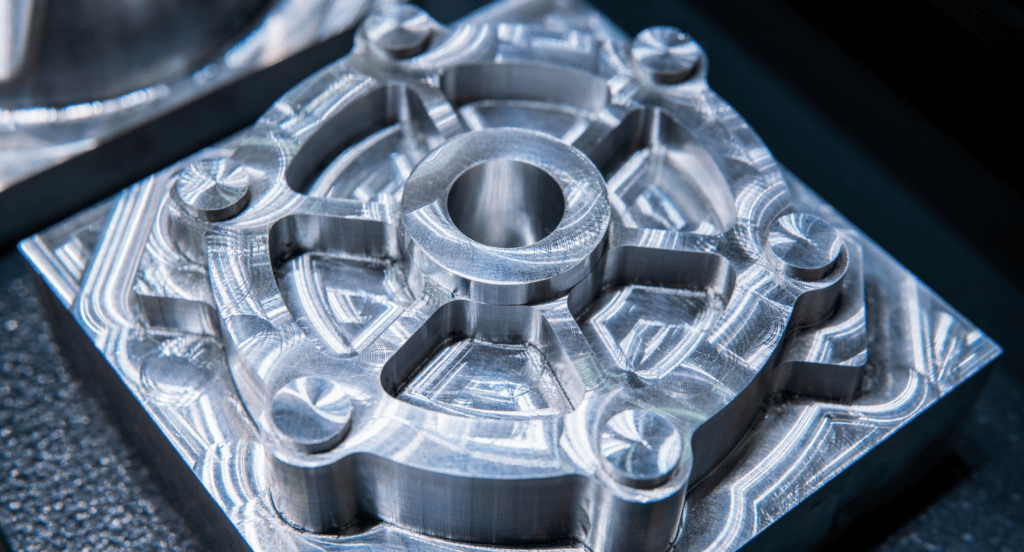

Get It Made stands out as more than just a manufacturing partner; they are a team of skilled engineers committed to understanding and fulfilling your project needs with high-quality, bespoke parts. Their expansive network of trusted manufacturing partners offers a broad spectrum of services, including CNC machining and injection moulding, tailored to meet specific client requirements.

Key Services: Their main services include Custom Metal Fabrication and CNC Milling. Custom Metal Fabrication offers tailored solutions, shaping metal into unique designs. CNC Milling provides precision cutting and shaping of metal components, ensuring detailed and accurate results.

Takeaway Note:

Get It Made excels in delivering custom fabrication solutions with unwavering attention to quality, precision, and lead times. However, for those seeking more localized production, the international aspect of their manufacturing network might not align with specific preferences for regional manufacturing.

4. KMF Group – Best in Integrated Metal Fabrication

City & Country: Staffordshire, United Kingdom

Established: 1971

KMF Group partners with leading Original Equipment Manufacturers (OEMs) across diverse sectors, offering comprehensive metal fabrication services for a wide array of products and assemblies. They operate within ISO 9001:2015 standards and hold AS9100 Aerospace Accreditation, affirming their commitment to consistent, high-quality product delivery.

Key Services: Their main services include Metal Forming and Metal Finishing. Metal Forming shapes metal into desired designs using various techniques such as bending or rolling. Metal Finishing smooths and polishes the surface, enhancing both the appearance and durability of the product.

Takeaway Note:

KMF Group excels in providing integrated, high-quality metal fabrication solutions, especially valuable for complex and demanding industry sectors. However, their specialized and broad-scale operations might present challenges for smaller businesses or those with more localized, low-volume requirements.

5. Grenville Engineering – Best in Customer-Centric Metal Fabrication

City & Country: Stoke-on-Trent, United Kingdom

Established: 1984

Grenville Engineering sets its sights on becoming a leader in the UK sheet metal fabrication industry, driven by a commitment to cutting-edge fabrication techniques. At the core of their operations lies a customer-centric approach, where collaboration with clients ensures the delivery of cost-effective yet high-quality solutions. Their goal is to lead the way in sheet metal fabrication by blending innovation with customer-focused service.

Key Services: Their main services include Sheet Metal Forming and Metal Punching. Sheet Metal Forming shapes metal sheets into specific designs, using techniques like bending and rolling. Metal Punching creates precise holes and cut-outs in the sheet metal, ensuring accurate and efficient production.

Takeaway Note:

Grenville Engineering shines in delivering bespoke metal fabrication solutions tailored to client needs. However, clients seeking more standardized, off-the-shelf products might find Grenville’s focus on custom solutions less aligned with their requirements.

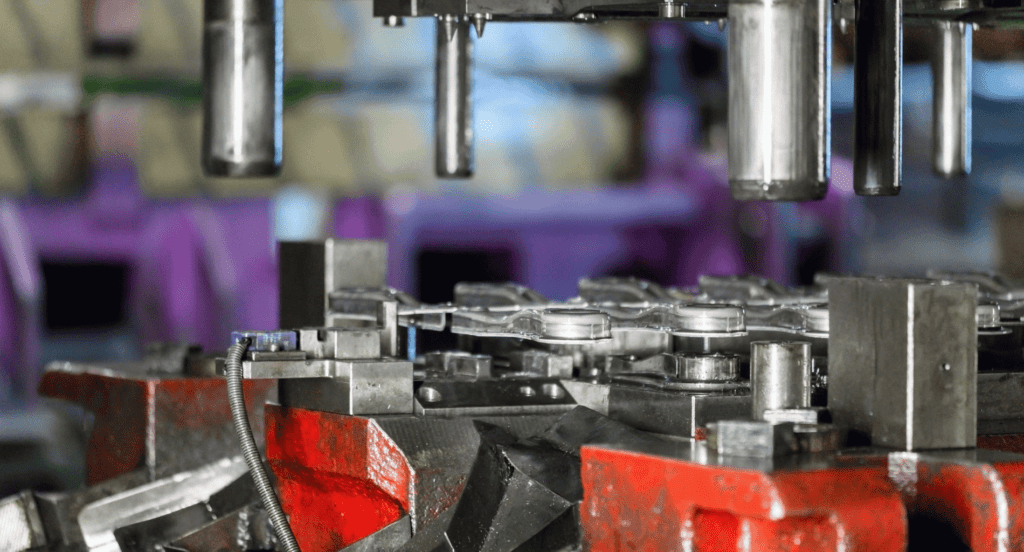

6. SAMS Fabrications – Best in Precision Engineering

City & Country: Norfolk, United Kingdom

Established: 1988

SAMS Fabrications focus on developing long-term relationships with customers by consistently delivering high-quality workmanship, on time and within budget. Customer satisfaction is their top priority, a key factor in their continued growth and success. SAMS Fabrications prides itself on delivering precision engineering of the highest quality, a commitment reflected in their well-established reputation.

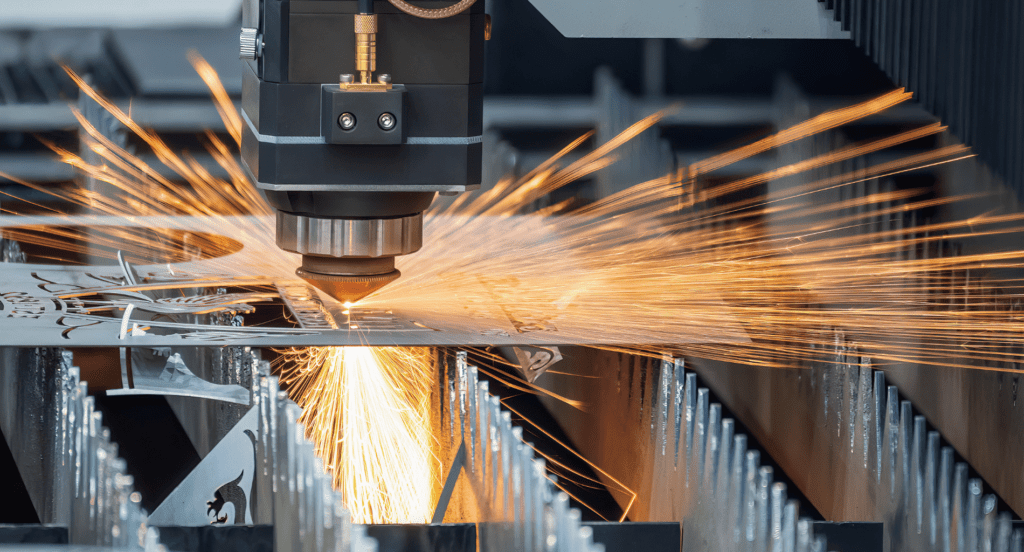

Key Services: Their main services include Laser Cutting and Welding. Laser Cutting provides high-speed, precise cutting of metal, creating clean edges and intricate designs. Welding ensures that metal components are securely joined, creating strong and durable structures for a wide range of applications.

Takeaway Note:

SAMS Fabrications excels in precision laser cutting and welding, prioritizing customer satisfaction and timely delivery. However, their focus on high-end technology may exceed the needs of clients seeking basic or traditional fabrication services.

4 Tips to Consider When Choosing Sheet Metal Fabrication Services in the UK

Selecting the right sheet metal fabrication service in the UK is a critical decision for businesses. According to Research Industry Network, the sheet metal fabrication services market size is expected to expand at a CAGR of 5.57% by 2028. To assist you in making an informed choice, here are four key aspects, each embedded with measurable criteria, to consider:

- Production Capacity of 10,000+ Units Per Month: Look for a fabricator that can handle over 10,000 units per month. This high-volume capacity ensures they can meet your demand without sacrificing quality. Additionally, such capacity indicates a well-established operation with the capability to handle large and complex orders efficiently.

This table highlights the importance of a fabricator’s production capacity:

| Factor | Description | Importance in Fabrication |

| High-Volume Capacity | Ability to produce over 10,000 units per month. | Ensures the fabricator can meet large-scale demands without compromising on quality. |

| Quality Assurance | Maintaining high-quality standards even at large volumes. | Indicates that the fabricator has robust quality control processes in place. |

| Efficiency in Handling Orders | Capability to manage large and complex orders efficiently. | Suggests a well-organized operation with optimized production processes. |

| Scalability | Adaptable to increasing demand without significant delays or issues. | Ideal for clients with growing needs or fluctuating order sizes. |

| Established Operation | Sign of a well-established and experienced fabricator. | Implies a reliable and stable provider with a track record of handling high-volume production. |

- Advanced Technology with 5-AxisCNC Machines: Prioritize fabricators equipped with 5-axis CNC machines. For instance, this advanced technology is a marker of their capability for complex and precise fabrication tasks. Fabricators with such technology are more likely to produce high-precision parts and can handle intricate designs more effectively.

- Certification Compliance, ISO 9001 & AS9100 Accredited: Ensure the fabricator is ISO 9001 and AS9100 accredited. These certifications demonstrate their commitment to maintaining high-quality standards in their production process. It also indicates that they adhere to international standards for quality management and product consistency.

- Industry Experience of 20+ Years in Business: Consider fabricators with over 20 years of industry experience. This longevity often reflects a proven track record of reliability and expertise. For example, experienced fabricators are more likely to have refined their processes over the years and can provide valuable insights and solutions to unique fabrication challenges.

Struggling to Find a Trusted Sheet Metal Fabrication Service in the UK?

In the quest for reliable and high-quality sheet metal fabrication services, many UK businesses face challenges in identifying a trusted provider. While considering local options, it’s also worth exploring partnerships with service providers in China, known for their cost-effectiveness, advanced technology, and large-scale production capabilities.

For businesses seeking a dependable solution, Zemetal emerges as a viable option. Their services not only encompass the high standards expected in the UK market but also bring the unique advantages of partnering with a globally recognized brand.Discover how Zemetal’s global experience and commitment to quality can elevate your business, offering you a competitive edge in a challenging market.

Conclusion

Finding a reliable sheet metal fabricator in the UK can be challenging, especially when you need high-quality work and tight deadlines met. Zemetal stands out with its advanced capabilities, helping you overcome production hurdles quickly and efficiently. We offer the expertise to get your projects done right.

In conclusion, this guide has introduced you to the top 6 sheet metal fabricators in the UK, helping you better understand your options. If you’re considering a manufacturer from China, we at Zemetal are ready to support your needs with precision and reliability. Contact us today to learn how we can help your business succeed!

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.