Is your business familiar with the transformative journey of screen printing throughout history? Exploring screen printing history offers more than just a story; it’s an exploration of a versatile art form that has shaped industries.

With extensive industry knowledge, we offer expert insights into screen printing history. Trust our expertise to guide you through the details and opportunities this history presents to your business.

Screen printing history has evolved, not only as an art form but also as a story of technological advancement, significantly impacting various sectors through production methods and market trends.

In this guide, we will navigate through the crucial moments of screen printing’s past, uncovering lessons and inspirations that are relevant to today’s business landscape.

Read on for enlightening discoveries.

1. Origins of Screen Printing

Screen printing’s journey in industrial applications began by decorating metallic surfaces using simple stencils. This early method, blending artistry with practicality, was instrumental in adding detailed designs and essential markings on various products. The focus was on both appearance and communicating key information through these prints.

As the demand for precise and long-lasting imprints on metal surfaces grew, screen printing techniques improved. By the late 1800s, the process had evolved, with better inks that adhered well to these materials. This advancement greatly enhanced the complexity and durability of designs, making it a vital part of industries, especially those involved in making durable goods.

2. Technological Advancements in Screen Printing

Building on the historical foundation of screen printing, the focus shifts to the technological advancements that have modernized the industry. Here are the transformative innovations shaping modern screen printing:

Automated Screen Positioning Systems

The introduction of automated screen positioning systems has significantly simplified the screen printing process on metal. These systems ensure precise alignment, reducing human error and increasing overall production efficiency. This technology is vital in large-scale production where consistency and speed are key factors in maintaining quality and meeting high demand.

UV Curing Technology

UV curing technology has brought a new dimension to metal screen printing, offering rapid drying times and enhanced print quality. This not only speeds up the production process but also ensures that the prints are more durable and resistant to fading. It’s particularly beneficial in sectors where quick turnaround and high-quality finishes are essential, like consumer electronics and tailored metal signage.

Integration with CNC Machining

The integration of screen printing with CNC (Computer Numerical Control) machining has opened up new possibilities in metal fabrication. This combination allows for the smooth transition from printing to cutting or engraving, enhancing the precision and capabilities of metal fabrication projects. It’s especially valuable in creating custom parts and prototypes where both printing and machining precision are required.

Mesh Technology

The development of advanced mesh technology has allowed for finer detailing in metal screen printing. This technology enables the creation of more detailed and precise patterns, essential for high-quality metalwork. It is particularly beneficial for industries requiring high precision, such as electronics and aerospace engineering.

3. The Rise of Commercial Screen Printing

Following the technological advancements in screen printing, the industry experienced a significant commercial boost, transforming how printed products are viewed. Here are the key areas where it has made a key impact:

Branding on Metal Packaging

Screen printing became essential for branding on metal packaging. It allowed for high-quality, vibrant prints directly on cans, tins, and other metal packaging, enhancing product appeal. This technique is key in differentiating products in the competitive consumer goods market.

Screen Printing in the Automotive Industry

The automotive industry embraced screen printing for adding decorative elements to metal parts. It enabled the application of detailed, durable designs on vehicle components, contributing to both aesthetics and brand identity. This method provides an efficient way to enhance the visual appeal of automotive parts.

Signage and Wayfinding in Public Spaces

Screen printing significantly impacted the production of metal signage and wayfinding solutions in public spaces. It offered a method to produce durable, weather-resistant signs that remain clear and legible over time. This application was particularly important in outdoor and high-traffic areas. Zemetal utilizing the benefits of screen printing provides strong and long-lasting metal signage solutions.

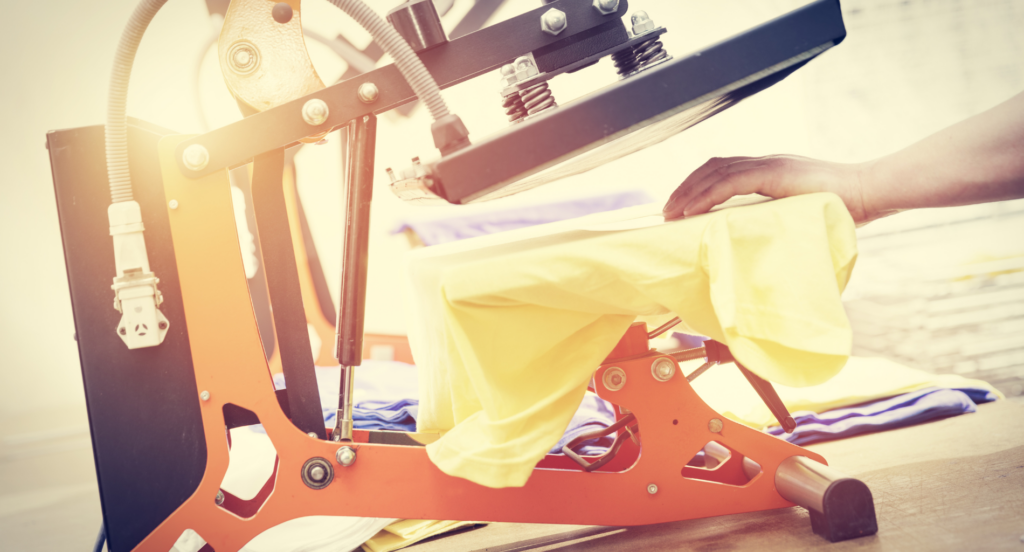

Screen Printing in Fashion Industry

In the fashion industry, screen printing introduced a new world of creativity. For example, designers utilized screen printing to apply detailed designs onto metal accessories and apparel, blending artistry with functionality. This technique enabled the creation of unique, custom metal pieces that stood out in the fashion world.

4. Modern Innovations and Digital Integration

Following the dramatic rise of commercial screen printing, the industry has witnessed a notable increase in modern innovations and digital integration, reshaping its future landscape. Here are the key developments:

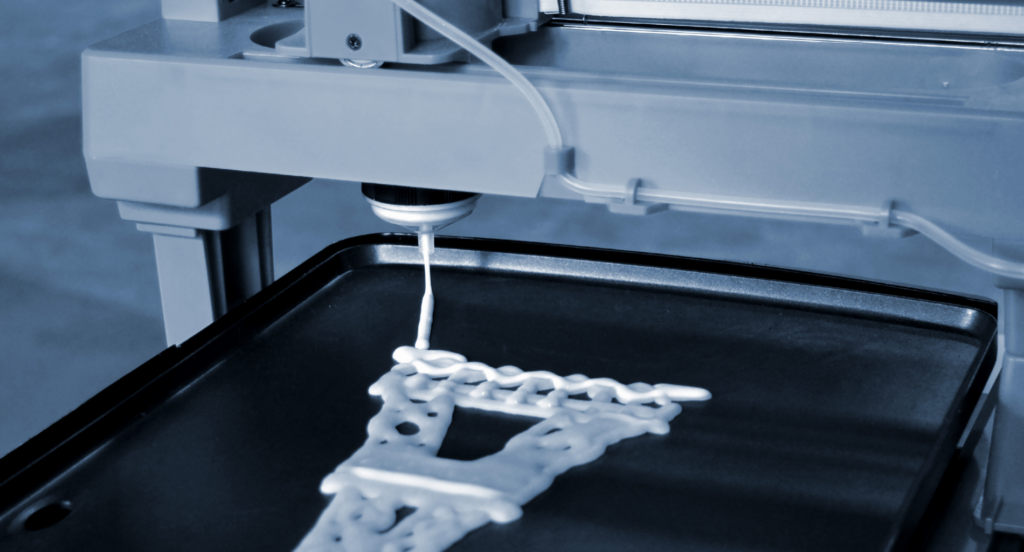

Integration with 3D Printing Technologies

Screen printing is increasingly being integrated with 3D printing technologies in metal fabrication. This combination allows for the addition of textured prints and layered designs on 3D metal objects. It’s particularly useful in customizing metal parts and prototypes, adding both functional and aesthetic value.

Responsive Inks for Interactive Metal Surfaces

Innovations have led to the development of responsive inks that change color or appearance under different conditions. When applied to metal surfaces through screen printing, these inks can create interactive and dynamic metal products. This technology is finding applications in safety indicators, consumer goods, and interactive art installations.

Automated Color Matching

Automated color matching systems have significantly improved the consistency of prints. This technology ensures that colors are reproduced accurately and consistently, which is crucial for branding and aesthetic purposes in metal products. It simplifies the process, reducing manual adjustments and errors. Zemetal has adopted these advanced systems to enhance the quality and precision of the services being offered.

Eco-Friendly Metal Printing Solutions

The metal fabrication industry is increasingly adopting eco-friendly screen printing solutions. These solutions involve using sustainable inks and solvents that are less harmful to the environment while maintaining print quality on metal. This approach not only reduces the ecological footprint but also aligns with the growing environmental regulations in the sector.

In the table below, we explore three prominent eco-friendly metal printing solutions, detailing their specific environmental benefits and their effects on print quality, illustrating how the metal fabrication industry is adapting to more sustainable practices.

| Type of Eco-Friendly Solution | Environmental Benefit | Impact on Print Quality |

| Sustainable Inks | Reduced VOC emissions | High-resolution and vivid colors |

| Green Solvents | Lower toxicity and biodegradability | Consistent and smooth application |

| Energy-efficient Equipment | Reduced energy consumption and waste | Enhanced precision and efficiency |

5. The Legacy and Future of Screen Printing

According to Research and Markets, screen printing is projected to experience 15.6% CAGR from 2022 to 2030. Here are some of its legacy and future:

The Role of Screen Printing in Modern Metal Artistry

Screen printing has become an essential tool in modern metal artistry. Artists and metalworkers utilize this to create detailed and visually stunning metal artworks. Whether it’s adding fine details to sculptures or producing limited-edition metal art pieces, it offers a versatile and precise means of expression. This blend of artistry and metal fabrication showcases its enduring relevance in crafting visually captivating metal pieces.

Screen Printing’s Timeless Influence

The timeless influence of screen printing on metal decoration has shaped the way metal surfaces are adorned and labeled. Throughout history, screen printing has been the preferred method for applying detailed designs, logos, and essential information onto metal components. This practice continues to elevate the aesthetics and functionality of metal products, from industrial equipment to consumer goods.

Sustainable Screen Printing Practices

In modern manufacturing, sustainability is key, and metal screen printing is going green. With eco-friendly inks and materials, it reduces environmental impact. Metal fabricators are embracing this eco-friendly approach, minimizing waste and emissions. Screen printing on metals is set to lead to eco-conscious metal decoration and labeling as sustainability gains importance in the industry.

The Future of Automated Screen Printing

The future of metal screen printing is all about automation and integration. Metal fabricators are adopting automated screen printing to boost efficiency and reduce costs. For example, integration of screen printing with other metal fabrication methods like laser cutting and CNC machining creates a smooth workflow for crafting detailed metal products. This transformative approach is shaping the future of metal decoration.

Conclusion

The rich history of screen printing reflects a journey of artistic and technological achievements. Understanding its history is not only for information but is also a strategic asset for businesses. This guide equips you with the knowledge to utilize its historical insights for future innovations and market adaptations.

If you are looking to integrate advanced screen printing methods into your business, Zemetal is your go-to partner. Reach out to us for solutions that align with your business needs and objectives.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.