Striving to achieve the perfect finish on aluminum products for your business? The secret lies in the precise and skilled application of sand blasting, a critical process in aluminum finishing.

As a seasoned expert in sand blasting aluminum, I bring years of hands-on experience and technical knowledge. My insights are built in industry best practices and innovative techniques.

Sand blasting aluminum is more than just a hard cleaning process; it’s an art that balances aggressiveness with delicacy, ensuring the integrity and aesthetics of the metal.

In this ultimate guide, we will delve into the complexities of sand blasting aluminum, covering everything from equipment selection to the fine distinction of polishing media choice and process optimization.

Read on to unlock the full potential of sand blasting in aluminum.

1. Basics of Sand Blasting Aluminum

Sand blasting aluminum is a fundamental process in surface preparation and finishing, essential for achieving a pristine, uniform appearance. This method involves propelling gritty materials against the aluminum surface under high pressure. This forcefully removes surface contaminants, like rust, scale, or old paint, revealing a clean, bare surface.

The choice of the sandy material is crucial; options range from traditional sand to more refined substances like aluminum oxide or silicon carbide, each providing different levels of coarseness and finish. The technique is not merely about cleaning; it’s also aimed at creating a specific surface texture that improves paint adhesion or achieves a desired look.

The process requires careful adjustment of various factors, including the pressure, nozzle type, and distance from the surface. Excessive pressure or the wrong sandy material can damage the aluminum, while too little force might not prepare the surface adequately. Mastering these elements is key to optimizing the sand blasting process for aluminum, ensuring a top-quality finish suitable for sophisticated business needs.

2. Benefits of Sandblasting Aluminum

Understanding the basics of sand blasting aluminum sets the stage for appreciating its numerous benefits. This process is not just a routine step in metalworking; it’s a game-changer for product quality and efficiency. Let’s break down the key advantages:

- Enhanced Surface Quality: Sand blasting aluminum creates a smooth, uniform surface, free from imperfections. This is crucial for applications where appearance and consistency are paramount, like in automotive or architectural components.

- Increased Durability: By removing surface contaminants and providing a roughened texture, sand blasting significantly improves the bonding strength of coatings. This results in a more durable, corrosion-resistant finish, essential for products exposed to harsh environments.

- Efficient Surface Preparation: Sand blasting is a swift and effective method to prepare aluminum surfaces. Compared to manual sanding or chemical treatments, it saves time and labor, streamlining production processes. For instance, a large batch of aluminum sheets can be prepared for painting in a fraction of the time it would take manually.

- Versatility in Applications: This technique is adaptable to various project needs. From delicate aluminum electronic components to robust architectural structures, sand blasting can be fine-tuned for different aluminum grades and product types, showcasing its versatility.

3. Types of Aluminum Suitable for Sand Blasting

After exploring the benefits of sand blasting aluminum, it’s important to understand that not all aluminum types respond the same way to this process. Here are the primary types of aluminum:

Pure Aluminum (Series 1xxx)

Pure aluminum has high corrosion resistance and excellent workability, is a prime candidate for sand blasting. This series, especially popular in the electrical and chemical industries, responds well to sand blasting, which enhances its surface finish without compromising its natural corrosion resistance. For example, sand blasting pure aluminum sheets used in chemical tanks can increase their durability and resistance to chemical exposure.

Aluminum Alloy – Copper (Series 2xxx)

The 2xxx series, typically alloyed with copper, offers increased strength. This makes it ideal for aerospace components. Sand blasting these alloys effectively removes surface imperfections and prepares them for coatings that protect against environmental stressors. However, care must be taken to avoid over-blasting, which can damage the surface integrity due to the alloy’s relative softness.

Aluminum Alloy – Manganese (Series 3xxx)

Aluminum-manganese alloys (3xxx series) are known for their moderate strength and excellent formability. They are commonly used in general sheet metal work where higher strength is required. Sand blasting these alloys provides a uniform finish, essential for aesthetic applications like building facades or automotive parts, ensuring a consistent appearance and texture.

Aluminum Alloy – Silicon (Series 4xxx)

The 4xxx series, alloyed with silicon, offers good weldability and resistance to thermal shock. This makes them suitable for applications such as welding rods and brazing sheets. When sand blasted, these alloys exhibit improved surface adhesion properties, making them more receptive to subsequent welding or brazing processes, enhancing the overall strength and durability of the welded joints.

Aluminum Alloy – Magnesium (Series 5xxx)

Series 5xxx, featuring aluminum-magnesium alloys, are renowned for their high strength, good corrosion resistance, and excellent marine environment performance. Ideal for shipbuilding and other marine applications, sand blasting these alloys ensures a clean, rough surface. This enhances the bonding of marine-grade paints and coatings, crucial for withstanding harsh oceanic conditions.

4. The Sand Blasting Process

Building on our understanding of the types of aluminum suitable for sand blasting, it’s crucial to delve into the sand blasting process itself. Below are the key steps involved in this intricate procedure.

#1 Choosing the Blasting Material

Selecting the right blasting material is the initial and crucial step in the sand blasting process. This decision largely hinges on the aluminum type and the desired finish. Common choices include materials like aluminum oxide, silicon carbide, and sometimes softer options like walnut shells for more delicate surfaces. From my perspective, aluminum oxide strikes an excellent balance, making it a versatile choice for various applications.

#2 Preparing the Aluminum

Prior to sand blasting, it’s essential to prepare the aluminum surface. This involves cleaning to remove any dirt, grease, or contaminants that might impact the blasting effectiveness. Based on my experience, thorough cleaning ensures that the blasting material interacts directly with the aluminum, leading to a more uniform and effective result.

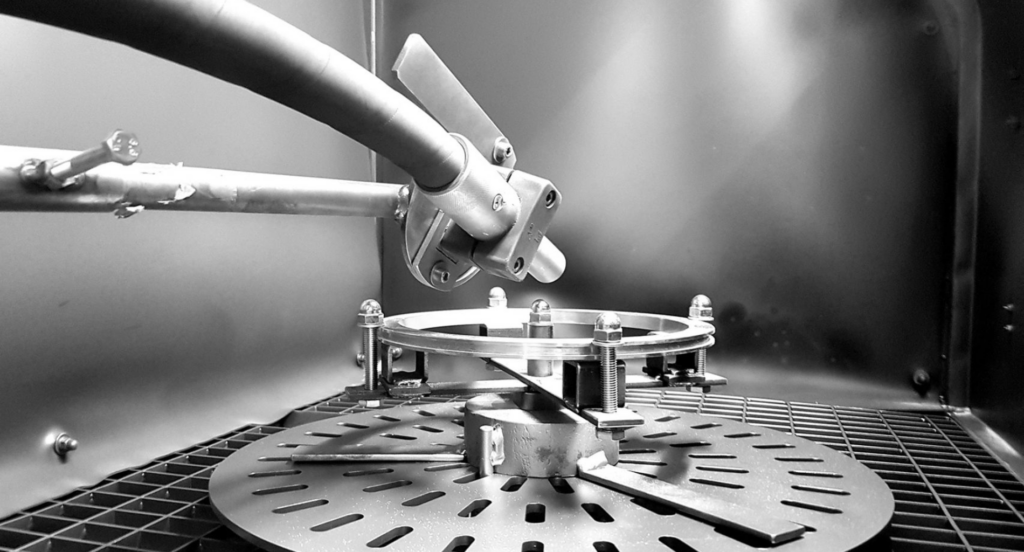

#3 Setting Up the Equipment

The subsequent step involves configuring the sand blasting equipment. This encompasses calibrating the air pressure, choosing the right nozzle size, and loading the chosen blasting material. The global sand blasting machines market size was estimated at USD 477.2 million in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 4.3% from 2024 to 2030 according to GrandViewResearch.

#4 The Blasting Process

Executing the actual blasting process demands skill and precision. The technician must consistently maintain the correct distance and angle to the aluminum surface for even coverage, avoiding any potential warping or damage to the material. Adjustments in pressure and speed are made depending on the aluminum grade and the finish being aimed for. This balance of technique and expertise is key to achieving an ideal finish.

#5 Post-Blasting Finishing

After the sand blasting, the aluminum is treated further. This usually includes cleaning to eliminate any leftover blasting material and a detailed inspection to ensure finish quality. Sometimes, a protective coating or primer is applied to the blasted surface to enhance its characteristics. This last step is vital in maintaining the quality and appearance of sand blasted aluminum.

5. Different Sand Blasting Techniques

The sand blasting process, fundamental in enhancing aluminum’s quality and durability, involves various techniques, each suited to specific requirements and outcomes. Here are the main techniques to know:

Dry Blasting

Dry blasting is the most commonly used technique in sand blasting. It involves propelling the blasting material, without any water, at high speed towards the aluminum surface. This method is highly effective for removing tough coatings, rust, and other surface contaminants. The absence of water makes it easier to manage and recycle the blasting material, making it a cost-effective choice for large-scale projects.

Wet Blasting

Wet blasting, also known as vapor or liquid blasting, incorporates water with the blasting material. This technique is less complicated compared to dry blasting, making it ideal for delicate aluminum surfaces where maintaining structural integrity is crucial. Personally, I have found wet blasting to be an excellent option for projects where surface preservation is as important as cleaning.

Bead Blasting

Bead blasting is a specialized technique that uses fine glass beads at a high pressure to clean the aluminum surface. This method is gentler than traditional sand blasting and is perfect for achieving a smooth, satin-like finish without causing damage to the metal. Bead blasting is my go-to technique for finishing delicate aluminum parts, as it effectively cleans without altering the metal’s dimensional properties.

6. Applications of Sand Blasting on Aluminum

Exploring the different sand blasting techniques highlights their versatility, leading us to the various applications of sand blasting in aluminum. Below are the main areas where this process plays a crucial role.

Aerospace Industry

In the aerospace industry, sand blasting is extensively used to prepare aluminum parts for further treatments like anodizing or painting. The process ensures that surfaces are free from contaminants and have the right texture for coatings to adhere properly. This is particularly important in aerospace, where the durability and reliability of components are paramount.

Automotive Manufacturing

The automotive sector relies heavily on sand blasting for preparing aluminum components. Whether it’s for engine parts, body panels, or decorative trims, sand blasting provides a uniform surface for subsequent treatments. I have seen during Zemetal services how this process significantly improves paint adhesion and corrosion resistance, which are critical factors in automotive manufacturing.

Architectural Applications

In architecture, sand blasted aluminum is widely used for facade panels, decorative elements, and structural components. The process not only cleans the aluminum but also imparts a visually pleasing, matte finish that’s highly sought after in modern architectural designs. My experience in this field has shown that sand blasting can transform ordinary aluminum into an aesthetic element, enhancing the overall appearance of buildings.

Electronics and Appliance Manufacturing

Sand blasting also finds its application in the manufacturing of electronic devices and household appliances. The process is used to prepare aluminum casings and components, ensuring they are clean and ready for finishing treatments. The gentle yet effective nature of sand blasting makes it ideal for delicate electronic parts, where maintaining the integrity of the components is as important as their aesthetic appeal.

7. Common Challenges in Sand Blasting Aluminum

The wide applications of sand blasting in aluminum highlight its importance, yet this process is not without its challenges. Listed are the main obstacles commonly encountered in sand blasting aluminum:

Maintaining Consistent Surface Finish

One of the primary challenges in sand blasting aluminum is achieving and maintaining a consistent surface finish across different parts and batches. Variations in blasting pressure, abrasive material, or even the angle at which the material hits the surface can result in inconsistencies.In my experience, diligent calibration of equipment and extensive training of operators are essential to overcome this challenge.

This table highlights key factors and solutions for maintaining a consistent surface finish in sand blasting aluminum, underscoring the importance of equipment calibration and operator training.

| Factor | Solution | Impact on Consistency |

| Blasting Pressure Variability | Precise Calibration of Blasting Equipment | Ensures uniform application of force |

| Abrasive Material Selection | Standardization of Abrasive Types | Reduces variation in surface abrasion |

| Blasting Angle Consistency | Training Operators in Technique | Promotes even surface treatment |

| Equipment Maintenance | Regular Check-ups and Repairs | Prevents fluctuations in performance |

| Operator Skill Level | Comprehensive Training Programs | Enhances expertise in handling nuances |

Preventing Warping

Aluminum, being a relatively soft metal, is susceptible to warping under excessive blasting pressure. This is especially true for thin sheets or intricate shapes. Warping not only affects the aesthetic of the component but can also compromise its structural integrity. From a personal standpoint, understanding the material’s limitations is key in mitigating the risk of warping.

Controlling Dust and Waste

Dust generation is an inherent part of the sand blasting process, posing environmental and health concerns. Efficient dust collection systems are essential to maintain a clean workspace and minimize health risks to operators. Additionally, the disposal of used abrasive material can present environmental challenges. Implementing effective waste management practices and recycling options are important steps in this issue.

Balancing Efficiency and Quality

Striking the right balance between operational efficiency and the quality of the finished product is another common challenge. There is often pressure to complete projects quickly, which can lead to rushed or subpar blasting work. However, sacrificing quality can result in product rejections or failures in application. Prioritizing efficient processes that do not compromise on quality is crucial for successful outcomes.

8. 3 Tips for Successful Sand Blasting

While addressing the common challenges in sand blasting aluminum, it’s also important to focus on strategies that lead to successful outcomes. See the following tips that can significantly enhance your sand blasting:

#1 Quality Control Checks

Implementing strict quality control checks throughout the sand blasting process is crucial. Regular inspections at different stages can help identify issues early, preventing costly reworks. For instance, checking the aluminum surface after blasting for any inconsistencies ensures that only the best-quality work progresses to the next stage. In a service-centric business, maintaining high standards through quality control is key.

#2 Training and Expertise

The skill and expertise of the operator play a significant role in the success of sand blasting services. Regular training sessions for operators to stay updated with the latest techniques and safety standards are essential. In my experience, a well-trained operator can make a significant difference in achieving a high-quality finish and operating efficiently.

#3 Optimal Blasting Technique

Adopting the right blasting technique is key to achieving the desired finish. This includes controlling the pressure, angle, and distance of the blasting nozzle from the aluminum surface. For example, using lower pressure and a finer blasting material can yield a gentle finish on thin sheets. Zemetal specializes in tailoring these variables to achieve the best results, ensuring a balance that meets the unique needs of each project.

Conclusion

In wrapping up this comprehensive guide on sand blasting aluminum, it’s clear that understanding the distinctions of this process can greatly enhance product quality and operational efficiency. The insights given here are designed to guide you through mastering this crucial technique in the aluminum industry.

For expert assistance and top-notch sand blasting services, turn to Zemetal. Our team of professionals is equipped to provide you with tailored solutions. For more information, do not hesitate to contact us.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.