Are you interested in elevating your surface treatment processes? This article highlights the transformative impact of sand and water blasting, key techniques for achieving superior surface finishes.

With years of industry experience, we offer a wealth of knowledge, ensuring you receive expert insights into these powerful cleaning methods.

Sand and water blasting offer precise and powerful surface cleaning and preparation. Their application in various industries showcases their versatility and effectiveness.

In this guide, we will explore the details of sand and water blasting, covering everything from basic principles to advanced applications and safety practices.

Read on to uncover the capabilities of these techniques.

1. Overview of Sand and Water Blasting

Sand and water blasting are two powerful techniques used for meticulous surface cleaning and preparation. Utilizing high-pressure streams, sand blasting employs abrasive materials for aggressive surface treatment, while water blasting uses high-velocity water for a more delicate approach. Both methods are crucial in achieving the desired surface texture and cleanliness.

The choice between sand and water blasting depends on the specific requirements of the task at hand. Sand blasting is ideal for tough, resilient surfaces needing deep cleansing or rust removal, whereas water blasting is suited for more sensitive surfaces, ensuring minimal damage. Understanding these distinctions is key to selecting the right method for best results in metal fabrication and related applications.

2. Advantages of Sand and Water Blasting for Metal Surfaces

After understanding the basics of sand and water blasting, exploring the benefits they offer is crucial to fully determine their full potential. Here are their key advantages:

- Efficiency in Surface Preparation: For metal surfaces, the efficiency of sand and water blasting is unmatched. They quickly eliminate rust, scale, and contaminants, ideal for preparing metal for painting or coating. This saves time and guarantees a superior finish on metal products.

- Versatility Across Metal Types: Sand and water blasting are versatile techniques. They are gentle on delicate metals and powerful on tougher alloys, making them suitable for various metal types without causing damage. This versatility is ideal for businesses handling diverse metal products.

- Cost-Effective Solutions: Sand and water blasting offer cost-effective surface treatment solutions, reducing the need for multiple cleaning methods and cutting labor costs. This is advantageous for businesses aiming to optimize their operational expenses.

- Improved Safety and Health Compliance: Modern sand and water blasting techniques prioritize safety and health by minimizing respiratory and other health risks compared to traditional methods, ensuring a safe workplace and adhering to industry standards.

3. Technological Innovations in Sand and Water Blasting

Building on the advantages, technological innovations have further enhanced the efficacy of sand and water blasting. Here are the key developments that happened:

Precision Control Systems

The introduction of precision control systems in sand and water blasting equipment has been a game-changer for metal processing. These systems allow for meticulous adjustment of pressure and flow, enabling highly precise and consistent surface treatment. This is particularly beneficial for complex metal structures where accuracy is essential.

High-Efficiency Filtration

Advancements in filtration technology have significantly improved the efficiency and environmental footprint of blasting processes. Modern filtration systems capture and recycle fine particles, reducing waste and enhancing the sustainability of the process. This is crucial in environments where cleanliness and environmental considerations are of utmost importance.

Digital Monitoring and Feedback Systems

The integration of digital monitoring and feedback systems in blasting equipment marks a major advancement. These systems provide real-time data on the blasting process, enabling operators to optimize settings for the best results on metal surfaces. This leads to higher quality finishes and more efficient use of resources.

This table outlines the key aspects and benefits of integrating digital monitoring and feedback systems in blasting equipment, emphasizing their role in enhancing quality and efficiency.

| Feature | Benefit | Impact on Blasting Process |

| Real-Time Data Collection | Allows immediate adjustments | Increases precision and quality |

| Optimization of Blasting Settings | Ensures ideal conditions for each project | Enhances surface finish quality |

| Resource Efficiency | Reduces waste and overuse of materials | Lowers costs and environmental impact |

| Quality Control | Ensures consistent output across projects | Maintains high standards in finishes |

| Predictive Maintenance Capabilities | Identifies potential equipment issues early | Reduces downtime and maintenance costs |

Integrated Safety Features

Modern sand and water blasting equipment now includes enhanced safety features. These include automated shut-off mechanisms, pressure regulators, and protective housings, which reduce the risk of accidents and ensure operator safety during surface treatment processes. Integrating such advanced equipment, Zemetal prioritizes both efficiency and safety in its comprehensive range of surface treatment solutions.

4. Applications in Various Industries

Following the exploration of technological innovations in sand and water blasting, attention shifts to distinct sectors where these methods significantly contribute. Here are some of the industries:

Oil and Gas Industry

In the oil and gas sector, sand and water blasting are essential for maintaining and restoring metal equipment and pipelines. These techniques efficiently remove rust, scale, and other deposits, crucial for preventing corrosion and ensuring the integrity and safety of pipelines and structures. This maintenance is vital for both onshore and offshore installations.

Rail Industry

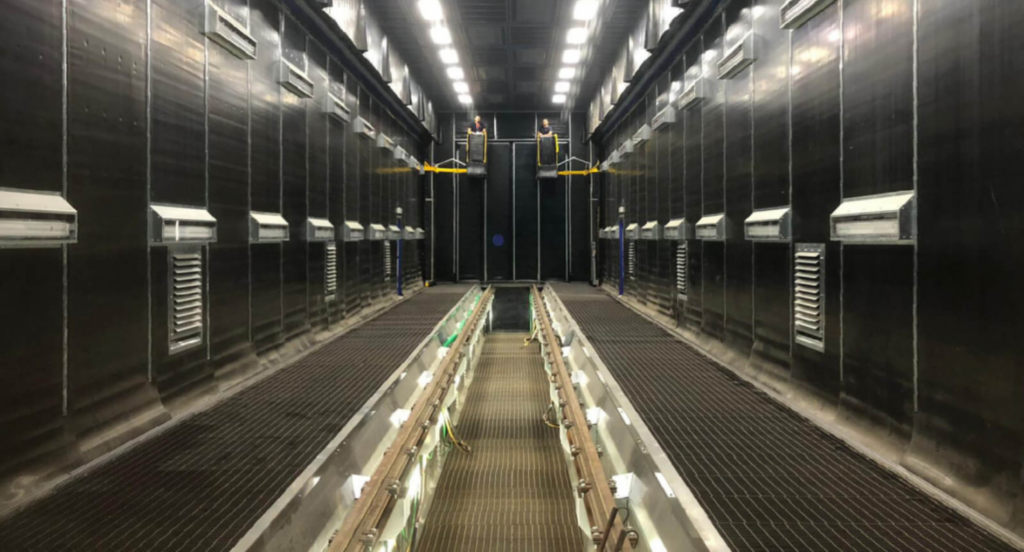

For the rail industry, these blasting methods are integral in restoring and maintaining metal components of trains and tracks. They effectively clean and prepare surfaces for painting or repairs, ensuring the longevity and reliability of rail infrastructure. This is especially important for the restoration of historical trains and the upkeep of modern rail systems.

Energy Sector

In the energy sector, particularly in renewable energy like wind turbines, sand and water blasting play a key role in preparing and maintaining metal surfaces. They are used to clean and condition turbine blades and other components, ensuring efficiency and longevity. This is crucial for both the construction of new energy installations and the maintenance of existing ones.

Defense and Military Sector

In the defense and military sector, these blasting techniques are employed for the maintenance and restoration of military vehicles and equipment. They are used for cleaning, removing old paint, and preparing surfaces for new coatings, crucial for both the appearance and functionality of military hardware. This process is key in maintaining the operational readiness and longevity of defense equipment.

5. Comparative Analysis: Sand Blasting vs. Water Blasting

Having explored the applications of sand and water blasting in various industries, it’s crucial to understand how these two methods compare their effectiveness and suitability. Here are the key areas of comparison:

Level of Efficiency

- Sand Blasting: Sand blasting is highly efficient for removing tough coatings and contaminants from surfaces. Its abrasive nature allows for quick and thorough cleaning, especially on hard metals. However, it can be less efficient on softer or more detailed surfaces where precision is key.

- Water Blasting: Water blasting is distinguished by its ability to clean delicate surfaces without causing damage. Its efficiency is enhanced when dealing with softer materials or in applications requiring a gentle touch. Additionally, water blasting is effective in reaching difficult-to-access areas due to its fluid nature.

Surface Finish Quality

- Sand Blasting: Sand blasting typically results in a rougher finish, ideal for preparing surfaces for coating. The abrasive action creates a textured surface, promoting better adhesion for paints or coatings. However, this method might not be suitable for applications requiring a smooth finish.

- Water Blasting: Water blasting, on the other hand, is known for delivering a smoother finish. This method is preferable when the final appearance is a concern, or for surfaces that will not be coated. The gentle action of water ensures minimal changes to the surface texture.

Environmental Impact

- Sand Blasting: Sand blasting can pose environmental concerns, primarily due to the dust and particles it releases into the air. Proper containment and cleanup are necessary to reduce its environmental impact. Additionally, the disposal of used abrasive material must be handled responsibly.

- Water Blasting: Water blasting is generally more environmentally friendly, producing less airborne debris. The use of water reduces the need for chemical cleaners, contributing to a greener process. However, water consumption and potential runoff need to be managed carefully.

Cost Analysis

- Sand Blasting: Sand blasting can be more cost-effective for larger, less delicate projects. The equipment and materials used in sand blasting are generally less expensive. However, the cost of waste disposal and protective measures can add up.

- Water Blasting: Water blasting may involve higher initial costs, especially for advanced equipment capable of regulating pressure and temperature. The operational costs are often higher due to the energy required to generate high-pressure water. However, savings in cleanup and waste disposal can balance these expenses.

Application Suitability

- Sand Blasting: Sand blasting is highly suitable for heavy-duty industrial applications, like removing rust from metal structures or preparing surfaces for painting. It’s ideal for jobs requiring aggressive surface etching. However, it may not be the best choice for delicate or precision tasks.

- Water Blasting: Water blasting shines in applications requiring a gentler approach, such as cleaning historical monuments or delicate machinery. Its versatility makes it suitable for a range of surfaces, including softer metals and plastics. This method is preferred for precision cleaning without surface damage.

6. Best Practices and Safety Protocols

Building on the insights from the comparative analysis, it’s essential to focus on the best practices and safety protocols of sand and water blasting. Here are key considerations to ensure best results and safety:

Standard Operating Procedures

Standard operating procedures (SOPs) are crucial in metal blasting operations to ensure consistency and safety. These procedures should outline the step-by-step process, including setup, operation, and shutdown of blasting equipment. Adherence to these SOPs minimizes the risk of accidents and ensures the longevity of both the equipment and the metal surfaces being treated.

Personal Protective Equipment (PPE)

Personal protective equipment is vital for safeguarding operators during metal blasting processes. Operators should wear protective gear like helmets with visors, heavy-duty gloves, and appropriate respiratory protection to guard against metal dust and abrasive particles. Regular inspections and maintenance of PPE are also essential to guarantee consistent and effective protection at all times.

Maintenance and Care of Equipment

Proper maintenance and care of blasting equipment are essential. Routine checks and servicing prevent malfunctions and ensure the equipment operates at optimal efficiency. This includes regular cleaning, replacing worn-out parts, and ensuring that all safety features of the blasting equipment are fully functional. Zemetal implements strict safety protocols to keep blasting equipment in top condition.

Emergency Procedures

Having well-defined emergency procedures in place is essential for handling unforeseen incidents during metal blasting operations. These procedures should include immediate response steps for equipment malfunctions, accidents, and exposure to hazardous materials. Regular drills and training for all staff will ensure quick and effective responses in emergency situations, minimizing risks and potential damages.

7. 4 Tips for Choosing the Right Method for Your Needs

As per Accumen Research and Consulting, the global abrasive blasting media market is projected to experience a CAGR of 6.5% from 2023 to 2032, indicating significant growth during this period. Here are tips to consider:

#1 Assessing Project Requirements

When choosing between sand and water blasting for metal surfaces, it’s vital to evaluate the specific needs of the project. Consider the scale of the project and the desired outcome; for instance, sand blasting might be more suitable for aggressive material removal, while water blasting can be ideal for finer, more delicate finishes. The choice should align with the project’s goals and the metal’s properties.

#2 Material Considerations

Different metals react uniquely to sand and water blasting. For example, softer metals like aluminum may require the gentler approach of water blasting to avoid surface damage, whereas harder metals like steel can withstand the more abrasive nature of sand blasting. It’s essential to understand the properties of the metal working with to choose the method that preserves its integrity while achieving the desired surface quality.

#3 Budget Constraints

Budget is a key factor in deciding between sand and water blasting for metal surfaces. Generally, sand blasting can be more cost-effective, especially for larger or more roughened surfaces. However, if environmental regulations or cleanup costs are a concern, water blasting might prove more economical in the long run due to its cleaner operation and reduced waste disposal requirements.

#4 Environmental Considerations

Environmental impact plays a significant role in the choice of blasting technique. Water blasting is often the more environmentally friendly option, as it generates less airborne dust and can be used with recycled water. However, if water disposal or usage is a concern, the dry nature of sand blasting might be more suitable, provided appropriate dust collection systems are in place.

Conclusion

Sand and water blasting techniques emerge as crucial tools for enhancing surface treatment processes. This guide has offered an in-depth exploration of their capabilities and applications, providing a comprehensive understanding to guarantee optimal results in your surface treatment projects.

If you are looking for cutting-edge, efficient surface treatment solutions, Zemetal is your ideal partner. Contact us today for customized solutions to meet your unique operational needs.

Dive Deeper Into Our Resources

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.