Is professional sheet metal fabrication the key to enhancing product quality and operational efficiency? This vital process stands at the heart of the metalworking industry.

With a rich background in metal fabrication, the nuances and challenges of this sector are well-understood. This expertise forms the basis of reliable guidance.

Professional sheet metal fabrication represents a commitment to precision and resilience. It’s a blend of innovative methods and skilled artisanship, essential for meeting diverse metalworking demands.

The upcoming content will explore recent advancements, tools, and strategies in professional sheet metal fabrication. It aims to shed light on improving processes and product standards.

So let’s get started!

1. The Basics of Professional Sheet Metal Fabrication

Professional sheet metal fabrication is the process of cutting, shaping, and assembling metal into desired forms and structures. It involves various techniques like welding, bending, and cutting, using specialized equipment. This process is crucial in industries like automotive, aerospace, and construction. It’s fascinating to see how a simple metal sheet can be transformed into something so intricate and functional.

The industry’s growth is significant. According to LinkedIn, the Sheet Metal Fabrication Services market is projected to grow from USD 17,690.48 million in 2022 to USD 24,486.42 million by 2028, at a 5.57% CAGR. This growth reflects the increasing demand for precision metal parts in various sectors. This boom highlights the endless possibilities and the importance of keeping up with industry trends.

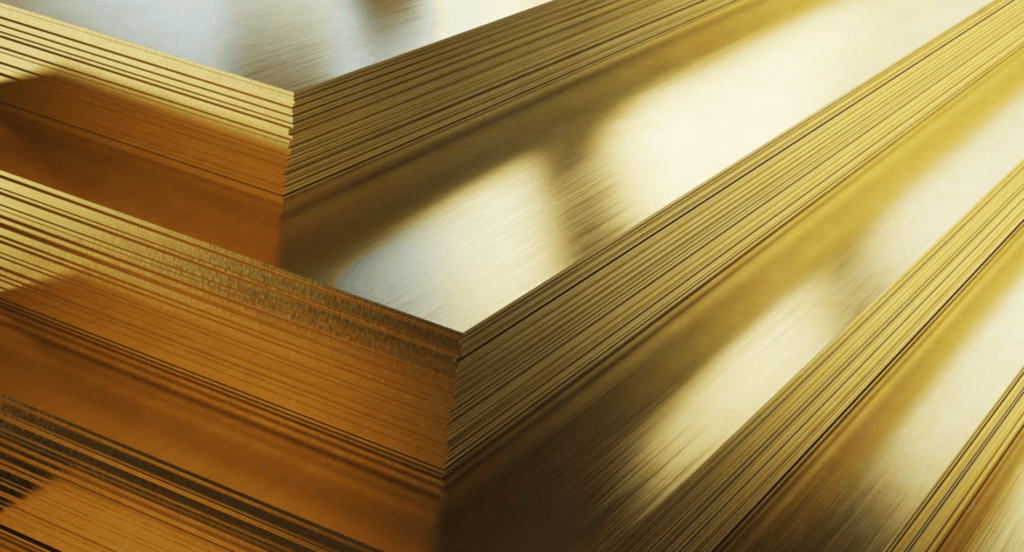

2. Materials Used in Professional Sheet Metal Fabrication

After understanding the basics of professional sheet metal fabrication, it’s essential to delve into the materials used in this process. Materials for sheet metal fabrication are tailored to project-specific needs. Below are the key materials used:

Steel

Known for its strength and durability, steel is a common choice for heavy-duty applications. It can withstand high stress without deforming, making it ideal for construction and industrial machinery. Steel’s versatility also allows for a range of finishes and coatings. It’s impressive how steel’s robustness shapes our modern world, from skyscrapers to automobiles.

Aluminum

Lightweight and corrosion-resistant, aluminum is ideal for aerospace and automotive parts. Its ability to conduct heat efficiently makes it suitable for heat exchange systems. Additionally, aluminum’s malleability allows for intricate designs in consumer products. The versatility of aluminum makes it a staple in advanced engineering fields.

Copper

Highly conductive and malleable, copper is often used in electrical components and roofing. It’s prized in electrical wiring due to its excellent conductivity. Copper’s natural patina over time also adds a unique aesthetic to architectural elements. Copper’s distinct characteristics make it invaluable in both functional and decorative applications.

Stainless Steel

Combining strength with corrosion resistance, stainless steel is popular in kitchen equipment and medical devices. Its hygienic properties make it a top choice for food processing and healthcare applications. Stainless steel’s sleek appearance also suits modern architectural designs. The reliability of stainless steel ensures safety and longevity in its applications.

Brass

Known for its aesthetic appeal, brass is used in decorative items and fixtures. Its resistance to tarnishing makes it a durable choice for ornamental applications. Brass also has a lower melting point, which simplifies casting and machining processes. For example, brass is often seen in classic door handles, ornate light fixtures, and musical instruments like trumpets and saxophones.

3. Key Techniques in Sheet Metal Fabrication

After exploring the materials used in sheet metal fabrication, it’s crucial to understand the key techniques that bring these materials to life. Below are the key techniques:

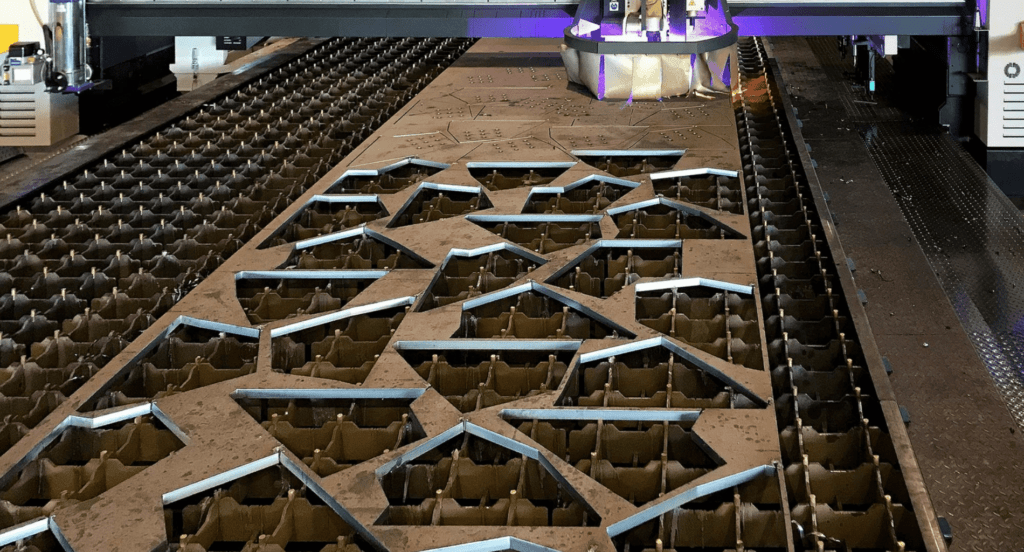

Cutting

This involves slicing sheets into desired shapes and sizes, often using lasers or plasma torches for precision. Laser cutting allows for intricate designs and high accuracy, while plasma cutting is preferred for thicker materials. Both methods offer speed and efficiency in the fabrication process. The choice between laser and plasma cutting depends on material thickness and the level of detail required.

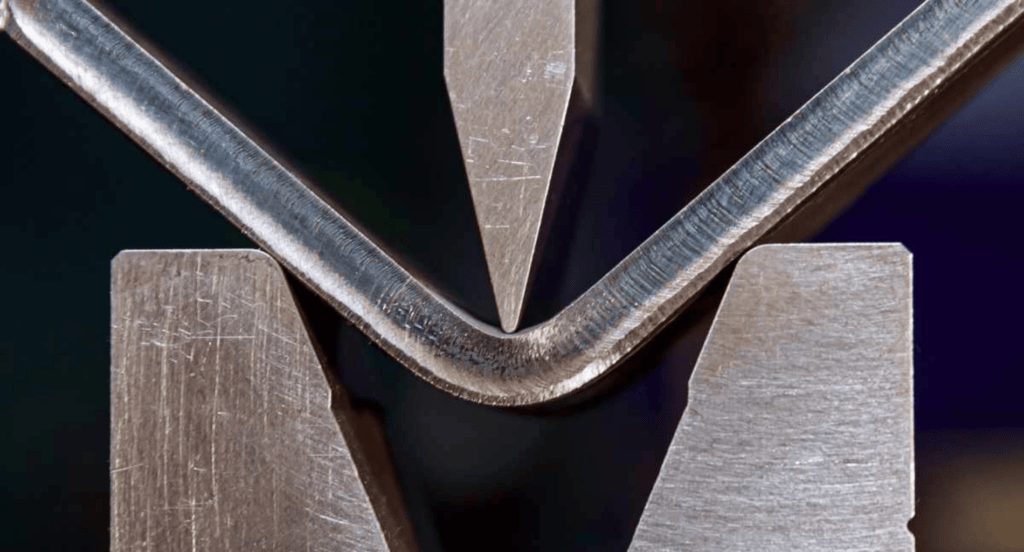

Bending

A process of deforming the metal into angles or curves, using press brakes and similar tools. This technique is essential for creating components with specific geometries, like enclosures and brackets. Computer-controlled bending machines ensure consistent and precise bends. Bending is also adaptable to various metal types, making it a versatile technique in fabrication.

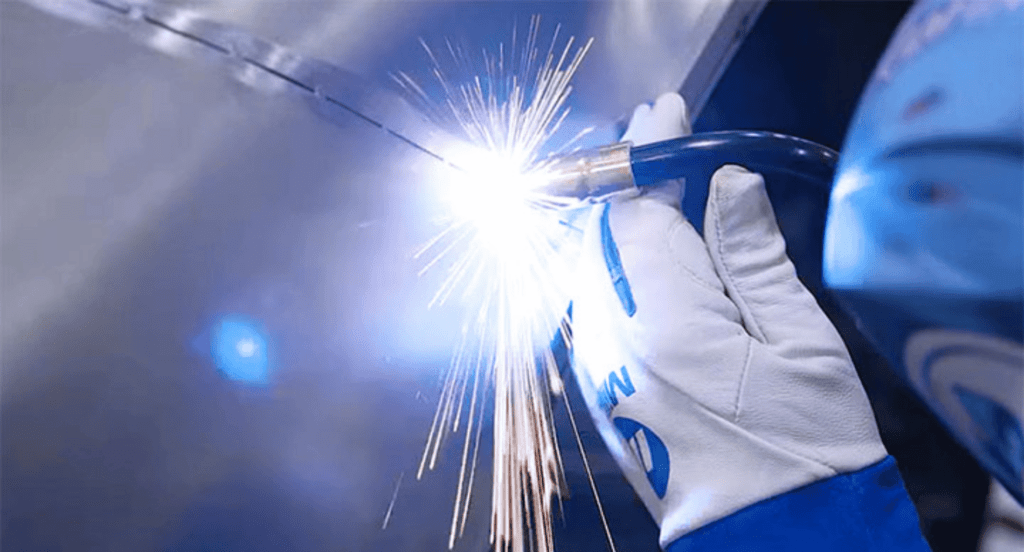

Welding

Joining metal pieces together securely, commonly using methods like MIG, TIG, or spot welding. Welding is critical for constructing sturdy structures and components. MIG welding is versatile for various metals, while TIG welding offers greater precision for thinner materials. Proper welding techniques are vital for ensuring the strength and durability of the final product.

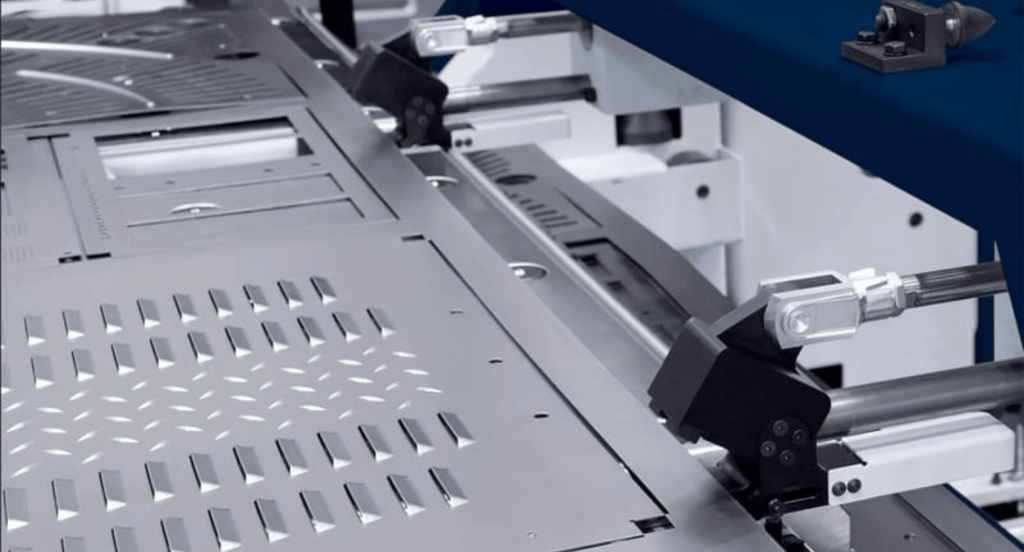

Stamping

This technique shapes or cuts the metal using a press, ideal for high-volume production. Stamping can produce large quantities of parts quickly, making it cost-effective for mass production. It’s commonly used for making automotive parts, household appliances, and metal components. Zemetal’s advanced stamping technology ensures top-notch quality and efficiency in every product we manufacture.

Punching

Involves creating holes or indents in the metal, often used for creating fixtures or assembly points. This method is perfect for adding functional features like screw holes or ventilation slots. Punching machines can be set up for repetitive patterns, ensuring uniformity in production. The precision of punching brings a level of detail and functionality that is crucial in modern metal designs.

4. Industry Applications of Sheet Metal Fabrication

Exploring sheet metal fabrication techniques leads to understanding their application across different industries. Below are its industry applications:

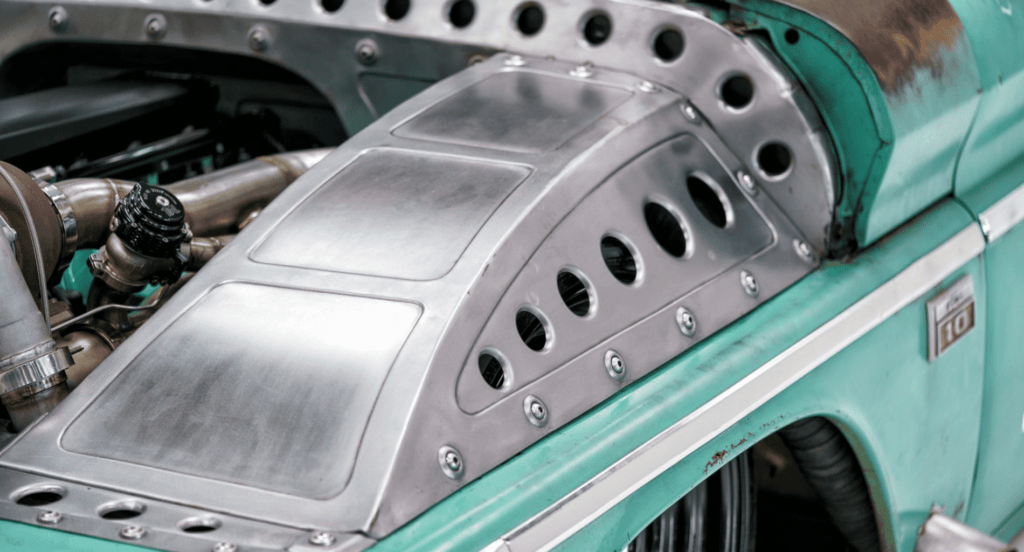

Automotive Industry

Fabrication techniques are used to create body panels, frames, and engine components, crucial for vehicle manufacturing. In this industry, metal fabrication contributes to the safety and aerodynamics of vehicles. Additionally, it allows for the customization and lightweight design of cars, enhancing fuel efficiency. It’s remarkable how metal fabrication shapes the cars we drive, making them safer, sleeker, and more efficient.

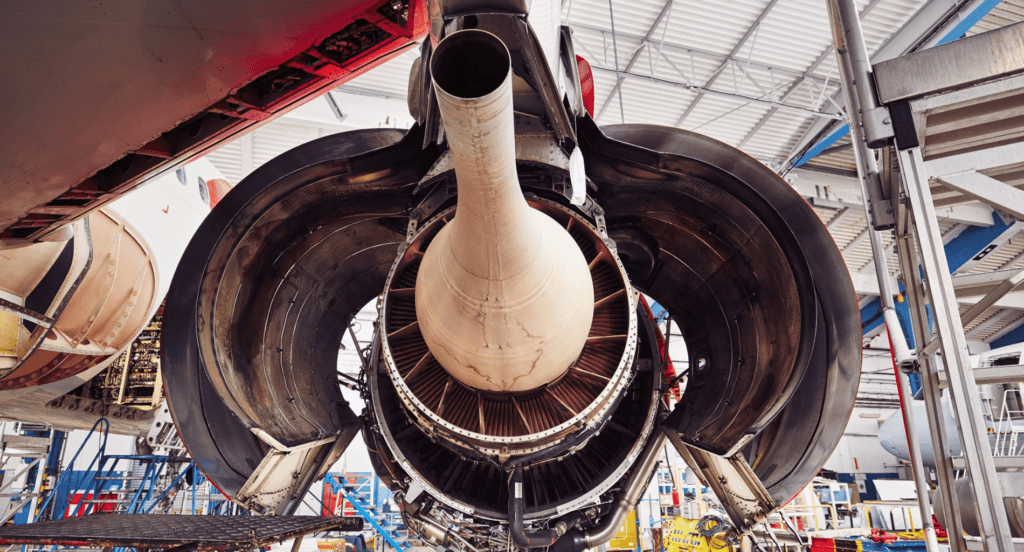

Aerospace Industry

Precision and high-strength materials are essential for parts like fuselages and wings in aircraft manufacturing. The accuracy of these components is critical for flight safety and performance. Aerospace fabrication often uses advanced alloys to withstand extreme conditions. This meticulous fabrication process is at the heart of ensuring the reliability and safety of every flight.

Construction Industry

Sheet metal is widely used for roofing, siding, and HVAC systems, offering durability and versatility. It provides solutions for both structural and aesthetic needs in building projects. Metal’s longevity and resistance to elements make it a preferred choice for construction. In construction, the use of sheet metal signifies a blend of strength and design flexibility.

Electronics Industry

Fabrication is key for producing enclosures, chassis, and heat sinks in electronics, where precision is paramount. These components protect delicate electronics and aid in heat dissipation. The adaptability of sheet metal fabrication allows for custom solutions in rapidly evolving tech designs. Sheet metal’s role in electronics underscores its importance in the age of technology.

Medical Industry

Customized metal parts are used in medical devices and equipment, requiring strict adherence to safety standards. This includes surgical tools, implants, and machinery parts. The ability to create sterile and biocompatible components is vital in this field. The precision in medical metal fabrication is a testament to its critical role in saving lives and improving health outcomes.

5. Safety Practices in the Fabrication Industry

Emphasizing safety practices is key after exploring industry applications in fabrication. Remember, in fabrication, safety isn’t just a practice, it’s a culture. Below are the safety practices in the fabrication industry:

Personal Protective Equipment (PPE)

Workers should always wear appropriate PPE, including safety glasses, gloves, and steel-toed boots. This gear protects them from hazards like sharp edges, sparks, and heavy objects. Consistent use of PPE is crucial in reducing workplace injuries and accidents. For instance, wearing safety glasses can prevent eye injuries from metal shards during cutting operations.

Regular Machinery Maintenance

Keeping equipment in top condition to prevent malfunctions and accidents. Routine checks and servicing ensure that machinery operates safely and efficiently. Neglecting maintenance can lead to dangerous equipment failures and costly downtime. Scheduled maintenance records and checklists can significantly enhance the longevity and safety of machinery.

Proper Training and Certification

Ensuring all workers are adequately trained and certified in operating machinery and handling materials. This training includes understanding the risks and the correct use of tools and equipment. Continuous education and skills updating are key to maintaining a safe work environment. Regular workshops and refresher courses are integral to reinforcing safety protocols and procedures.

Emergency Preparedness

Having clear procedures for emergencies, including first aid and fire safety protocols. Workers should be trained to respond effectively in various scenarios, including equipment malfunctions and medical emergencies. Regular drills and clear communication channels are essential for emergency preparedness. Mock drills boost a team’s emergency response time and efficiency.

Workspace Ergonomics

Designing workspaces to reduce strain and fatigue, thereby minimizing the risk of injuries. Ergonomic tools and equipment help prevent chronic injuries such as back pain and carpal tunnel syndrome. Well-designed workstations also improve efficiency and productivity. Incorporating adjustable desks and chairs can significantly reduce the risk of musculoskeletal disorders.

6. Challenges and Solutions in Sheet Metal Fabrication

Following the focus on safety practices, it’s vital to address the challenges and solutions in sheet metal fabrication. Below are their solutions:

Material Wastage

Minimizing scrap material through efficient design and nesting software. By optimizing layout and cutting patterns, wastage can be significantly reduced. This not only saves material costs but also contributes to environmental sustainability in the fabrication process. It’s amazing how smart design choices can lead to both economic and ecological benefits in fabrication.

Maintaining Precision

Utilizing advanced CNC machinery for consistent and accurate cuts. Precision is key in fabrication, and CNC technology ensures that each piece meets stringent specifications. This reliability is crucial in industries where even minor deviations can lead to significant issues. The accuracy of CNC machines brings a level of perfection that manual processes cannot match.

Cost Management

Balancing quality and cost-effectiveness in material selection and process optimization. Finding the right balance involves choosing materials that meet both budget and performance requirements. Streamlining processes also helps in reducing unnecessary expenses while maintaining high standards. Efficient cost management is the backbone of competitive pricing in the fabrication market.

Workforce Training

Providing ongoing training and upskilling to keep pace with technological advancements. As technology evolves, so must the skills of the workforce. Continuous training ensures that employees are proficient in the latest fabrication techniques and machinery, leading to better quality and efficiency. Investing in workforce training is investing in the future of fabrication.

Environmental Impact

Implementing sustainable practices and recycling to reduce the environmental footprint. Sustainable fabrication involves using recyclable materials, reducing waste, and conserving energy. These practices not only benefit the environment but also enhance the industry’s reputation and compliance with regulations. The shift towards eco-friendly practices is shaping the future of the fabrication industry.

The table below showcases strategies for implementing sustainable practices and recycling in the fabrication industry, emphasizing the dual benefits of environmental conservation and improved industry reputation.

| Sustainable Practice | Implementation Method | Environmental Benefit |

| Use of Recyclable Materials | Sourcing Sustainable Inputs | Reduces waste and promotes circular economy |

| Waste Reduction | Process Optimization | Minimizes material usage and landfill contributions |

| Energy Conservation | Energy-efficient Machinery | Lowers carbon footprint and operational costs |

| Water Recycling | Closed-loop Systems | Conserves water resources and reduces disposal needs |

| Emissions Reduction | Pollution Control Technologies | Improves air quality and complies with regulations |

7. Innovations and Trends in Sheet Metal Fabrication

Following our discussion of challenges and solutions, let’s explore the latest innovations and trends in sheet metal fabrication.Below are the key innovations and trends:

3D Printing in Metal Fabrication

Integrating 3D printing for complex components, allowing for more intricate designs and reduced material waste. This technology enables the creation of parts that are difficult or impossible to make with traditional methods. It also accelerates the prototyping process, significantly shortening the time from design to production.

Automation and Robotics

The use of automated machinery and robotics for increased precision and faster production times. Robotics in fabrication leads to consistent quality, particularly in repetitive tasks. Additionally, it reduces the physical strain on workers and can operate continuously, increasing overall productivity. It’s truly remarkable how robotics are transforming the way we think about and execute fabrication processes.

Smart Factory Integration

Implementing IoT and AI to create smart factories that optimize workflow and reduce human error. This integration leads to better resource management and predictive maintenance, reducing downtime. Smart factories also provide real-time data analytics, allowing for quick decision-making and process optimization. This technological evolution is making factories smarter, safer, and more efficient than ever before.

Eco-Friendly Techniques

Adopting greener practices, such as using renewable energy sources and recyclable materials. These sustainable practices not only reduce the environmental impact but also can lower operational costs. Eco-friendly approaches are increasingly demanded by consumers and can enhance a company’s market appeal. Zemetal is leading the way in sustainable sheet metal fabrication, setting a benchmark for the industry.

Advanced Material Use

Experimenting with new alloys and composite materials for better performance and durability. These advanced materials can offer improved strength-to-weight ratios and resistance to corrosion. Their use is expanding possibilities in various sectors, including aerospace and automotive industries, where material performance is critical.

Conclusion

This guide has been a valuable resource in understanding the key aspects we’ve discussed. It’s designed to help make informed decisions and move forward smoothly. Additionally, it provides insights into the latest trends and practices in the field.

If you’re looking for more specialized assistance, Zemetal is here to help. Don’t hesitate to contact us anytime for personalized support and solutions.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.