Has anyone curious about how powder coating can transform your metal products, giving them an edge in quality and durability? Understanding the powder coating definition is the first step in exploring this innovative finishing process.

Drawing on extensive experience in metal fabrication services, this guide offers a trusted perspective on why understanding powder coating is essential for your business.

Powder coating is more than just a finishing touch; it’s a vital enhancement for any metal product. Exploring powder coating shows its vital impact on product appearance and durability.

In this article, you’ll gain comprehensive insights into powder coating, from its basic principles to its transformative impact on various industries.

Read on to discover powder coating’s transformative impact.

1. Understanding Powder Coating

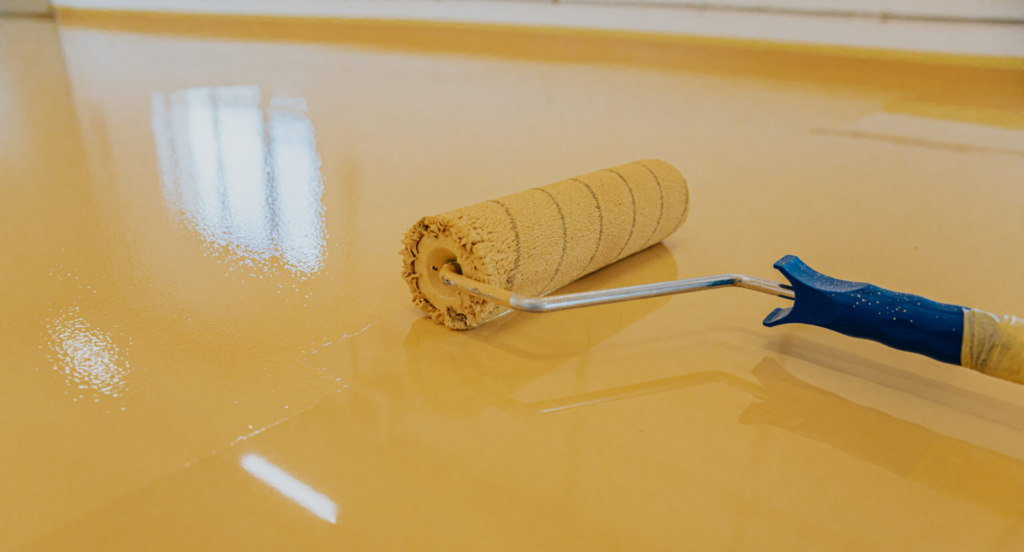

Powder coating, utilizing electrostatically charged particles of pigment and resin, offers a finish that is not only uniform and durable but also visually appealing. This technique’s effectiveness in improving both aesthetics and resistance to damage is reflected in its market growth. As per IndustryARC, the powder coatings market is set to reach US$18.2 billion by 2027, emphasizing its expanding popularity in diverse industries.

Additionally, unlike liquid paints, powder coating releases negligible volatile organic compounds (VOC), making it an environmentally friendly option. Its versatility in color and texture options suits a wide range of applications, making it a preferred choice in various industries, from automotive to home appliances.

2. Benefits of Powder Coating

After understanding the essence of powder coating, it’s clear why this technique is widely preferred. Now let’s take a look at the key benefits that make it stand out in the industry:

Durability and Longevity

Powder coating is renowned for its exceptional durability. This finishing method provides a thicker and more consistent coating than traditional paint, leading to increased resistance against scratches, chipping, and corrosion. This resilience makes it ideal for products subjected to harsh conditions, ensuring a longer lifespan and maintaining aesthetic appeal over time.

Environmental Friendliness

One of the most notable advantages of powder coating is its environmental friendliness. Unlike liquid paints, it contains no solvents and releases minimal volatile organic compounds (VOCs). Brands like Zemetal, prioritizing eco-friendly practices, this aspect is particularly appealing. This process not only meets stricter environmental regulations but also improves workplace safety by reducing exposure to harmful chemicals.

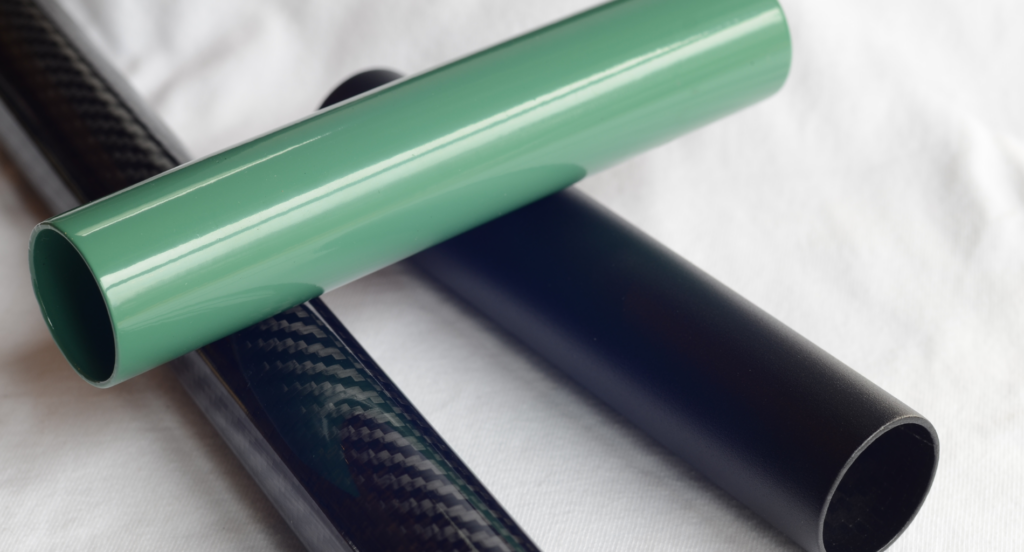

Aesthetic Flexibility

Powder coating offers an impressive range of colors and finishes, from high gloss to matte and textured options. It’s exciting to see how this flexibility allows for creativity in design. For example, automotive parts can be finished with a sleek, high-gloss coat or a rugged, textured finish, depending on the desired look. This versatility meets diverse needs, establishing powder coating as a popular choice in many sectors.

3. Key Components of Powder Coating

After exploring the benefits of powder coating in various industries, it’s important to understand the key components that make this technology so effective. Let’s delve into the essential elements of powder coating:

- Resin and Pigments: The backbone of powder coating, resins provide the primary structure, while pigments offer the desired color. Together, they form the coating’s base, ensuring durability and visual appeal.

- Curing Agents: These components react with the resin to form a tough, protective layer. The choice of curing agent influences the coating’s properties, such as flexibility and resistance to environmental factors.

- Additives: Additives enhance specific properties like flow characteristics, gloss levels, and texture. They are crucial for tailoring the powder coating to specific application requirements.

- Application Equipment: Quality application equipment ensures an even and efficient coating process. Having used advanced electrostatic spray guns, the precision and uniformity they provide in coating application is impressive. This equipment is vital for achieving optimal coating results.

4. Types of Powder Coatings

Building on the key components of powder coating, it’s important to recognize the different types available. Each type offers unique properties and benefits suitable for various applications. Let’s explore the most common types of powder coatings:

Thermoset Powder Coatings

Thermoset powder coatings are widely used due to their durability and high-quality finish. When cured, they react chemically to form a strong, heat-resistant bond. This type is ideal for items exposed to high temperatures or harsh conditions. It’s particularly favored for automotive parts, home appliances, and outdoor furniture, providing a long-lasting, attractive finish.

Thermoplastic Powder Coatings

Thermoplastic powder coatings, unlike thermosets, do not undergo a chemical change during curing. They are known for their flexibility and impact resistance. Commonly used in industries requiring a thicker, more protective coating, these coatings are easy to apply and can be re-melted and reformed. This versatility makes thermoplastic coatings a practical choice for many applications.

Specialty Powder Coatings

Specialty powder coatings, such as those provided by Zemetal, cater to specific industry needs. These can include coatings with enhanced UV protection, anti-graffiti properties, or increased electrical insulation. Specialty coatings are tailored to meet unique challenges and requirements, demonstrating the adaptability and innovation within the powder coating industry.

5. Industry Applications of Powder Coating

With a variety of powder coatings available, their applications span across numerous industries. Each sector leverages the unique benefits of these coatings to enhance product quality and durability. Here are some different industries that utilize powder coating:

Automotive Industry

In the automotive sector, powder coating is crucial for both functionality and aesthetics. It’s used on frames, wheels, bumpers, and engine parts for its durability and resistance to corrosion. The ability to withstand extreme conditions and retain color vibrancy makes it a preferred choice for automotive manufacturers. This ensures long-lasting protection and appeal in vehicles.

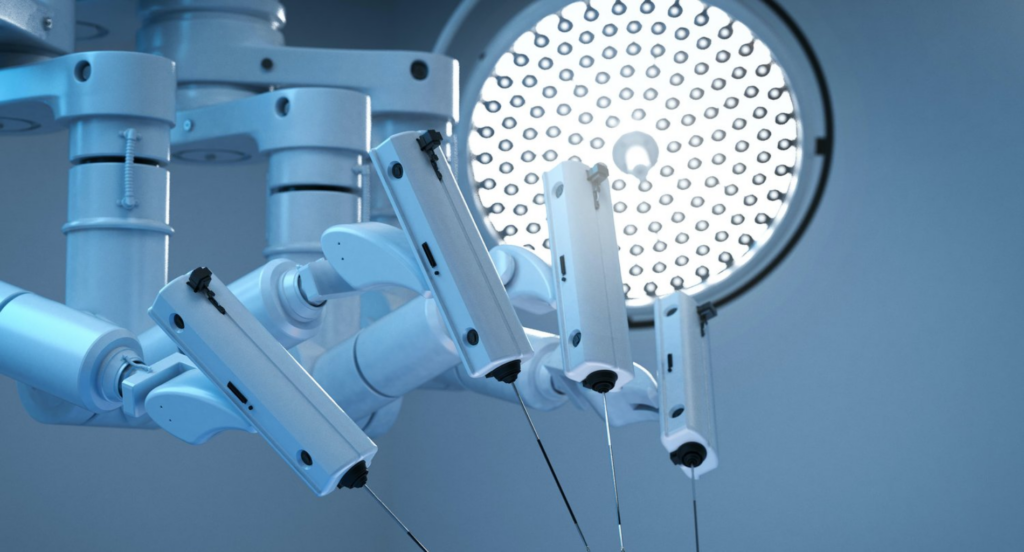

Medical Industry

In the medical industry, powder coating is applied to a wide range of equipment, from hospital beds to surgical tools. Its non-toxic, hypoallergenic properties are crucial in this sensitive environment. The coating’s resistance to chemicals and ease of cleaning also make it an ideal choice for maintaining hygiene and preventing contamination in medical settings.

Electronics Industry

Powder coating is extensively used in the electronics industry for its insulative properties and durability. It provides a protective layer on electrical components, enclosures, and casings, safeguarding against moisture, heat, and electrical interference. This ensures a longer lifespan and reliability of electronic devices, an essential aspect in an industry where precision and safety are paramount.

6. Powder Coating vs. Traditional Liquid Coating

Havings discussed the industry applications of powder coating, it’s insightful to compare it with traditional liquid coatings. Each type has its own unique properties and applications. Let’s delve into how powder coating stands against specific types of liquid coatings:

Powder Coating vs. Acrylic Coatings

Powder coating is known for its exceptional durability and efficiency in application. This type of coating is also more resistant to chipping, fading, and wearing compared to traditional liquid coatings. Acrylic coatings, while offering good color retention and a glossy finish, tend to be less durable than powder coatings. They tend to chip and scratch more easily and typically need a solvent for application, releasing volatile organic compounds.

Powder Coating vs. Epoxy Coatings

The key advantage of powder coating over epoxy coatings is its superior outdoor durability. Powder coatings resist UV damage and weathering better than epoxies, maintaining their color and finish for longer periods. Epoxy coatings are known for their strong adhesion and chemical resistance, making them ideal for indoor applications. However, they yellow and degrade under UV exposure, making them less suitable for outdoor use.

Powder Coating vs. Polyurethane Coatings

Powder coatings are highly efficient and environmentally safer, emitting zero or near-zero VOCs. They are also known for their wide range of textures and color options, along with excellent durability. Polyurethanes coatings offer great flexibility, impact resistance, and are known for their smooth finish. However, they typically involve the use of solvents, leading to higher VOC emissions.

7. Challenges and Solutions to Powder Coating

Despite the benefits highlighted in powder coating versus traditional liquid coating, there are inherent challenges in this method. Understanding and addressing these challenges is key to harnessing the full potential of powder coating in various applications. Here are some key aspects to look at:

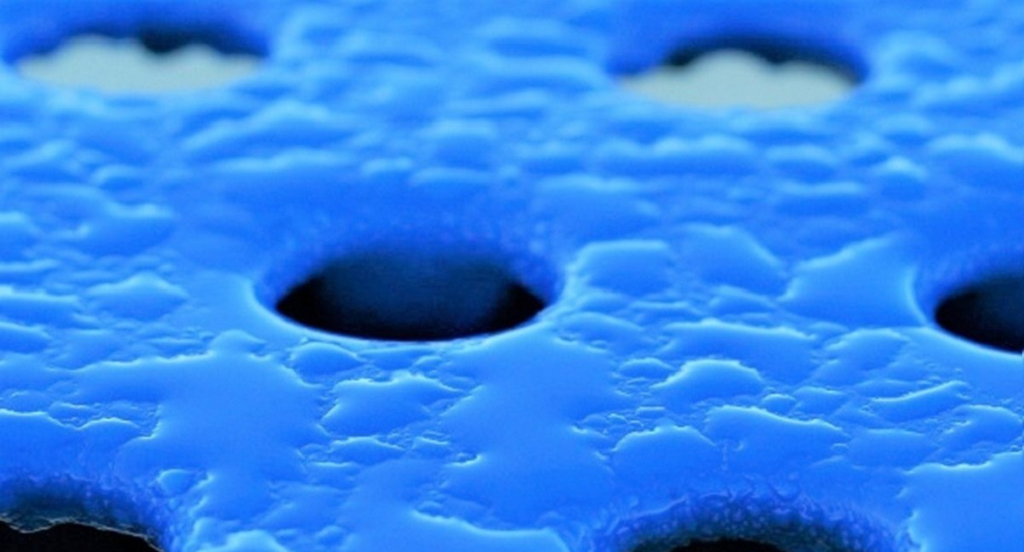

Faraday Cage Effect

The Faraday Cage Effect presents a significant challenge in powder coating, particularly when coating complex shapes with recessed areas. This effect, caused by powder coating’s electrostatic nature, repels charged particles from concave areas, resulting in uneven coverage and thin spots. To overcome this, technicians can adjust the electrostatic charge and use specially designed spray nozzles to reach difficult areas.

Difficulty in Achieving Thin Coatings

Achieving consistently thin coatings is a challenge in powder coating, as it tends to naturally result in thicker layers. This can be problematic for applications requiring precise dimensional tolerances or for parts that must retain fine details. To address this, the use of advanced spraying equipment with better control over powder flow and particle size is recommended.

This table delves into the challenges and solutions associated with achieving thin coatings in powder coating processes, especially important in applications requiring high precision and detail retention.

| Challenge | Solution | Importance in Powder Coating |

| Natural Tendency for Thickness | Optimized Powder Formulation | Reduces the risk of excessively thick layers |

| Precision in Dimensional Tolerance | Advanced Spraying Equipment | Ensures adherence to specific dimensions |

| Retention of Fine Details | Controlled Powder Flow and Particle Size | Preserves intricate details on surfaces |

| Uniformity of Thin Layers | Consistent Application Techniques | Achieves even coverage without buildup |

| Adaptability to Different Surfaces | Tailored Coating Strategies | Enhances suitability for varied materials |

Curing Time Constraints

Curing time constraints pose a challenge, as powder coatings often require longer curing times compared to liquid coatings, potentially slowing down production processes. One solution is to optimize the curing process using infrared or UV curing systems, which can significantly reduce curing times. Additionally, using faster-curing agents in powder coatings can reduce downtime and enhance productivity in busy production settings.

8. 3 Tips for Choosing the Right Powder Coating for Your Business

Navigating through the challenges and solutions of powder coating reveals the importance of selecting the right type for your specific business needs. Making an informed choice can significantly impact the efficiency and quality of your products. Here are some specific tips to make an informed decision:

#1 Assessing the Application Environment

Selecting the right powder coating involves considering the specific environment where the product will be used. For example, for outdoor applications, such as exterior automotive parts, opt for a powder coating with excellent UV resistance and weatherability, like a super-durable polyester. This guarantees the coating endures long-term sun exposure and weather changes, preserving the product’s appearance and structure.

#2 Understanding the Material Compatibility

Different materials have unique reactions to powder coating. It’s important to select a coating that is compatible with the intended substrate. For heat-conductive metals such as aluminum, choosing a powder that cures at lower temperatures is advisable to avoid substrate damage. It’s essential to match the powder properties with the material’s characteristics to ensure optimal adhesion and finish.

#3 Considering Aesthetic Requirements

The final product’s aesthetic appeal is paramount. Assessing available finishes, textures, and colors is key. For a desired appearance, like a high-gloss finish on automotive parts, the right coating that combines this look with performance is essential. Various powders provide unique effects, including metallic or pearlescent finishes, enabling the creation of distinct and attractive designs.

Conclusion

Powder coating offers a versatile and durable solution, enhancing both the functionality and appearance of metal products. This guide has shed light on its various aspects, helping businesses better understand and utilize this technique.

For those seeking exceptional powder coating services, Zemetal is the go-to expert. Reach out to us for solutions that align with your business’s specific needs.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.