Are you ready to elevate your business with the precision of laser cut steel services? This cutting-edge technology is reshaping the way we approach metal fabrication.

As an expert in metal fabrication, I bring a wealth of knowledge to help you navigate the complexities of laser cut steel.

Laser cut steel services stand at the forefront of technological advancement in any field, offering unmatched precision and efficiency that can transform your production process.

In this guide, we’ll delve into the benefits, applications, and critical aspects of laser cut steel services, providing you with valuable insights for your business.

Read on to be enlighten in this journey.

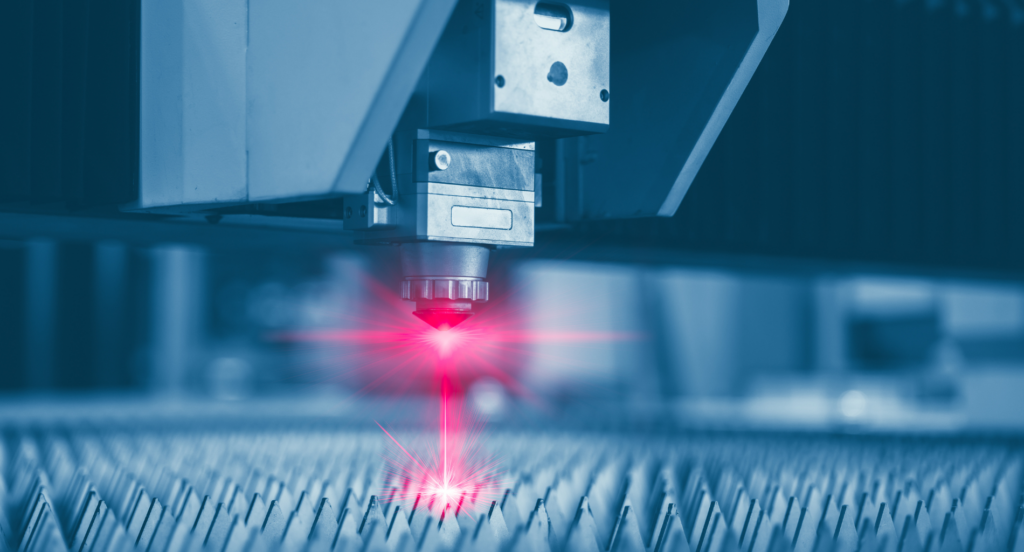

1. The Science Behind Laser Cutting

Laser cutting stands as a marvel of modern engineering, employing a highly focused beam of light to melt, burn, or vaporize material with extraordinary precision. This process involves directing the laser through a nozzle, usually accompanied by a flow of inert gas, which ejects the molten material and creates a precise cut. It’s fascinating to witness how a mere beam of light can manipulate robust metals with such finesse.

Technology’s versatility allows for detailed designs and consistent cuts on a variety of materials, from steel to aluminum. Its precision and speed not only enhance efficiency but also reduce waste, making it an environmentally conscious choice in metal fabrication.

2. Benefits of Laser Cut Steel Services

Building on the intricate science of laser cutting, it’s clear that this technology offers several significant advantages. Let’s explore some of these benefits that make laser cut steel services a standout choice in metal fabrication:

Precision and Accuracy

Laser cutting is renowned for its exceptional precision. The ability to produce detailed designs and maintain consistency across multiple pieces is unparalleled. This accuracy ensures that each component fits perfectly in its designated place, reducing the need for additional processing. The laser’s highlights accuracy minimizes material waste, making it a cost-effective solution for complex projects.

Speed and Efficiency

The speed at which laser cutters operate is a major advantage. They can quickly move through material, significantly reducing production times. This efficiency is not just about speed; it’s about the ability to maintain quality at a rapid pace. For businesses, this translates to faster turnaround times and the ability to meet tight deadlines, a crucial factor in staying competitive.

Versatility and Customization

Laser cutting’s adaptability is a key advantage, as it can process a diverse array of metals with varying thicknesses and sizes. This versatility enables the creation of custom parts and designs, such as detailed metal panels for architecture or precise components for machinery. For example, producing complex, custom-designed gears for automotive applications becomes streamlined with laser cutting.

3. Customization and Design Flexibility in Laser Cutting

Laser cutting shines when it comes to customization and design flexibility, offering a range of possibilities that are unmatched by traditional methods. Here are some key aspects where this technology excels:

- Diverse Material Handling: The ability to cut through various materials with the same equipment makes laser cutting a versatile choice for different industries. From delicate fabrics to robust metals, the technology adapts seamlessly, allowing brands like Zemetal to cater to a broad range of client needs.

- Efficient Design Changes: The digital nature of laser cutting means that design changes can be made rapidly and implemented immediately. This efficiency is vital in fast-paced environments where time is of the essence, and it’s always impressive to see how quickly ideas can become tangible products.

- Scalability of Production: Whether it’s a single prototype or a large batch of intricate parts, laser cutting scales efficiently to meet demand without sacrificing quality. This scalability ensures that projects of all sizes can be accommodated, making it a suitable choice for businesses at every level.

- Personalized Solutions: Laser cutting’s flexibility allows for personalized solutions, ensuring that each project can be tailored to specific requirements. This customization ranges from artistic pieces to industrial components, underscoring the technology’s wide use and its impact on innovation across fields.

4. Applications of Laser Cut Steel in Various Industries

Laser cutting steel’s versatility makes it a valuable asset in various industries. Here are some key sectors where its impact is particularly notable, showcasing how this technology adapts to different industrial needs:

Commercial and Retail Industry

In the commercial and retail industry, laser cut steel offers unique opportunities for branding and design. Zemetal utilizes this technology to create custom signage, display units, and fixtures that are not only functional but also visually appealing. The ability to cut detailed designs and patterns in steel allows for innovative branding solutions that stand out in the competitive retail space.

Energy Industry

The energy sector, including renewable energy, relies heavily on laser cut steel for producing durable and precise components. In wind turbines, for example, laser cutting is used to fabricate parts that can withstand harsh environmental conditions while maintaining efficiency. The precision of laser cutting in creating components for wind turbines is a testament to its role in advancing sustainable energy solutions.

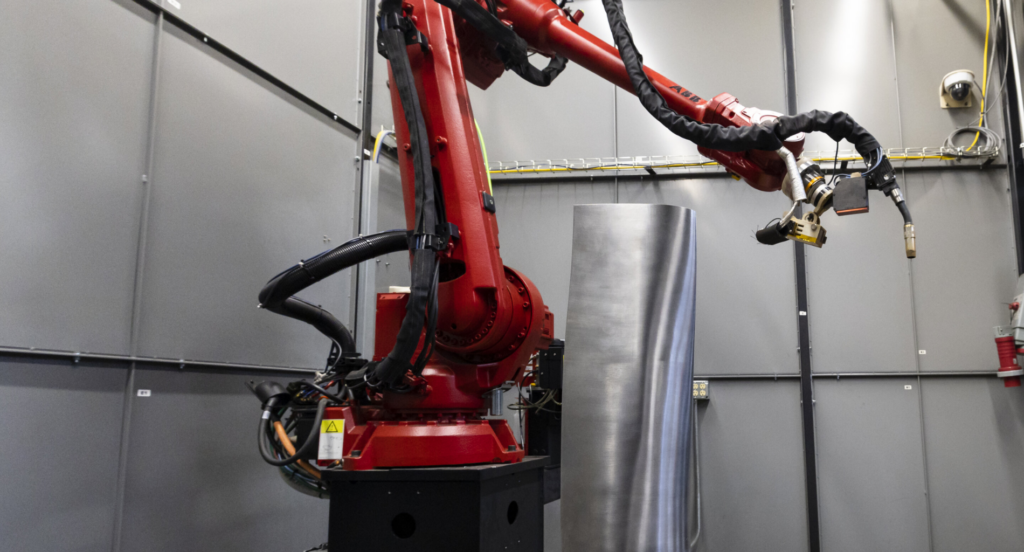

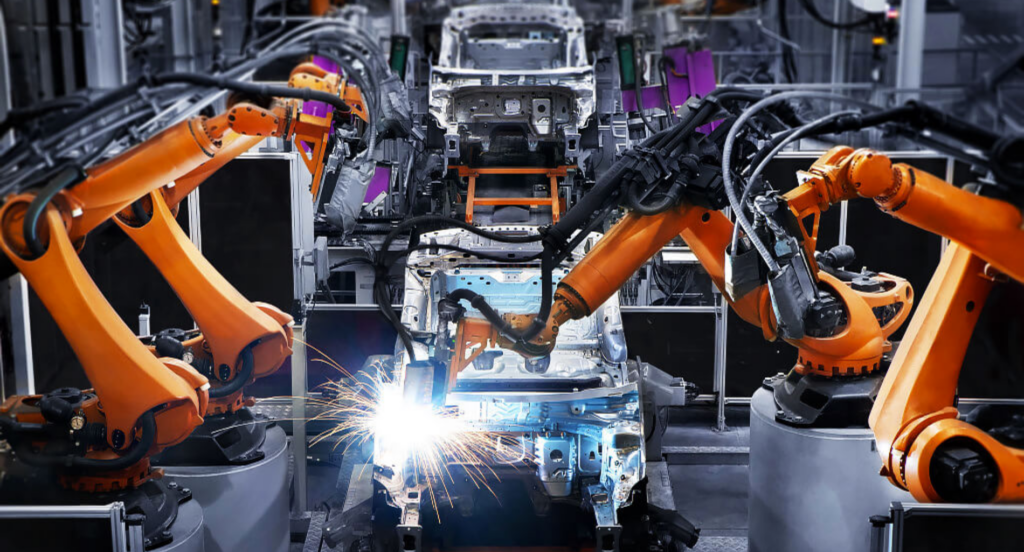

Automotive Industry

In the automotive indstry, laser cut steel plays a crucial role in manufacturing precision parts. From engine components to detailed body designs, the accuracy of laser cutting ensures parts fit seamlessly, enhancing vehicle performance and safety. This technology supports the production of both standard and custom automotive parts, contributing significantly to innovation and design in the industry.

5. Comparing Traditional Steel Cutting Methods with Laser Cutting

Having outlined laser cut steel’s diverse applications across industries, it’s valuable to contrast it with traditional steel cutting methods. Understanding these differences aids in choosing the right cutting technique for specific projects. Here are some comparisons to understand their distinct characteristics:

Laser Cutting vs. Plasma Cutting

Laser cutting is renowned for its precision and clean edges, perfect for intricate shapes and details with minimal heat distortion. On the other hand, plasma cutting excels in cutting thicker materials quickly, ideal for large-scale projects. However, it lacks the fine precision of laser cutting and is less suited for detailed work due to its wider kerf and greater heat distortion potential.

Laser Cutting vs. Water Jet Cutting

Laser cutting excels in terms of speed, particularly for thin materials, and boasts energy efficiency with minimal setup time. Its adaptability to different patterns enhances its versatility in design. In contrast, water jet cutting excels in handling thick materials and a variety of substances, avoiding heat stress, thus preserving material integrity. However, it tends to be slower than laser cutting for detailed metal work.

6. Challenges and Limitations of Laser Cut Steel Services

While laser cut steel services offer numerous benefits, they also come with specific challenges and limitations. Understanding these can help in making informed decisions and optimizing the use of this technology in various applications. Let’s explore some of these challenges and limitations:

High Initial Investment Cost

The primary challenge with laser cutting technology is the high initial investment cost. Setting up a laser cutting system involves significant financial outlay for the equipment itself, along with associated costs like installation, training, and maintenance. The high cost not only impacts affordability but also limits the widespread adoption of laser cutting technology, especially in regions with limited financial resources.

Material Sensitivity to Heat

Laser cutting, despite its precision, can sometimes lead to issues with materials sensitive to heat. Heat sensitivity can lead to warping and deformities, particularly in thin metals, making managing heat output crucial for maintaining product integrity. This sensitivity limits the range of materials suitable for laser cutting. Materials vulnerable to thermal damage limit the range of suitable applications for laser cutting.

7. The Future of Laser Cut Steel Services

The horizon for laser cut steel services is rapidly expanding, incorporating advancements and innovations that promise to redefine the industry. Let’s delve into some of the key developments expected to shape the future of this field:

Technological Advancements

The continuous evolution of laser technology promises even greater precision and speed in the future. Advancements in laser power and control systems are expected to increase efficiency, reduce waste, and expand the range of materials that can be cut. This technological progress will likely open new avenues for detailed and complex designs, pushing the boundaries of what can be achieved with laser cut steel.

Expanded Material Compatibility

The ongoing research and development in laser technology are likely to broaden its compatibility with a variety of materials. This expansion will not only include different types of metals but also extend to composites, plastics, and other non-traditional materials. Such versatility will unlock new creative and industrial applications, making laser cutting a more universally applicable technology.

This table outlines the potential expansion of material compatibility in laser technology, highlighting the diverse range of materials and the new opportunities this advancement will bring.

| Material Type | Description | Potential Applications |

| Various Metals | Adaptability to different metal types | Industrial and construction uses |

| Composites | Cutting and shaping composite materials | Aerospace and automotive industries |

| Plastics | Precision cutting of various plastics | Consumer goods and medical devices |

| Non-Traditional Materials | Enabling work with innovative materials | Expanding to novel industrial uses |

| Enhanced Material Thickness | Accommodating thicker materials efficiently | Broadening the scope of construction applications |

Increased Accessibility and User-Friendliness

Future developments in laser cutting are anticipated to significantly enhance user accessibility and ease of use. With intuitive software and streamlined interfaces, these systems are expected to become more approachable for a diverse range of users, from small businesses to individual hobbyists. This shift will promote wider use of laser cutting, encouraging innovation in numerous fields and applications.

8. 3 Tips for Choosing the Right Laser Cut Steel Service Provider

Amidst the laser cutting service market’s rapid growth, forecasted at a CAGR of over 7% as per Linkedin, choosing the right provider is key to capitalizing on this expanding demand for precision in various indsutries. Let’s examine the crucial factors to ensure your provider meets your specific needs and standards:

#1 Assessing Technical Capabilities

Assessing the technical capabilities of the service provider is crucial. Determine if they possess the latest laser cutting technology appropriate for specific needs. It’s important to understand their capacity to manage various materials and thicknesses, as well as their skill in executing complex designs. Providers equipped with a selection of advanced machinery are generally expected to offer higher precision and quality.

#2 Reviewing Past Projects and Reputation

Another crucial aspect is to review the provider’s past projects and reputation in the market. Look at their portfolio to gauge their expertise and the types of projects they have successfully completed. Reading testimonials and reviews can offer insights into their reliability and customer service quality.

#3 Analyzing Cost and Turnaround Time

Evaluating cost and turnaround time is essential. Receiving a reasonable rate for services while maintaining quality is vital. Review the pricing structure, including project, hourly rates or additional fees, to determine budget alignment. Also, clarify typical project completion timelines to confirm the ability to meet deadlines without compromising final product quality.

Conclusion

In navigating the complexities of laser cut steel services, this guide serves as a valuable resource, offering insights and practical tips to make informed decisions. It aims to enhance understanding and streamline the selection process for businesses in this field.

For those seeking expert laser cut steel services, Zemetal offers a combination of quality, precision, and customer-centric solutions. To discuss your requirements or for more information, feel free to contact us.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.