What if laser and engraving technology could transform approaches to metal fabrication? Imagine the new levels of precision and creativity it could unlock.

As a seasoned professional in metal fabrication, I’ve witnessed the significant impact these technologies have on efficiency and precision.

Laser and engraving technologies are significantly transforming the metal fabrication industry with their unmatched accuracy and adaptability, reshaping business approaches to metal projects.

This article will explore the benefits of laser and engraving for your business, highlighting recent innovations and practical uses.

Read on to discover how laser and engraving elevate metal fabrication.

1. Understanding Laser Technology in Engraving

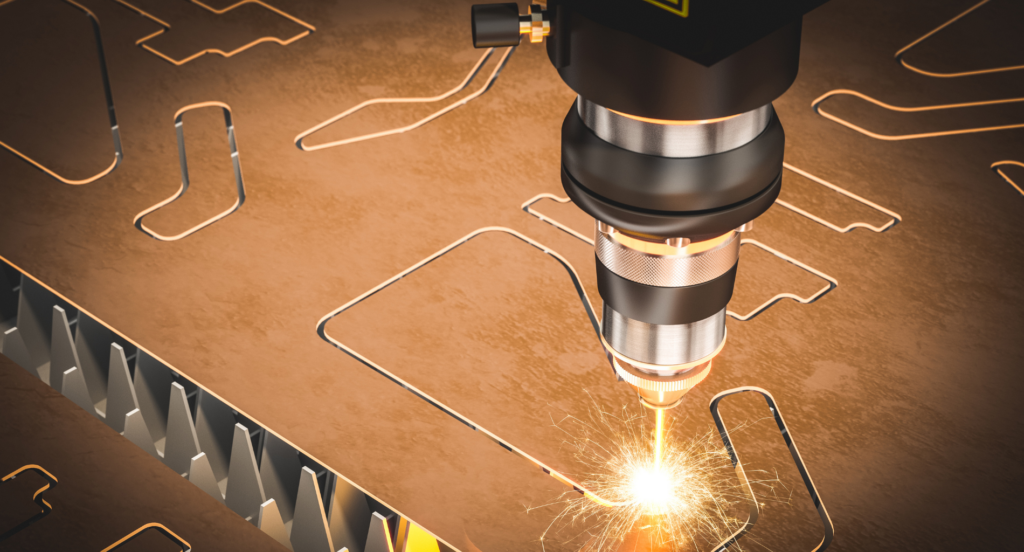

Laser engraving technology harnesses the power of focused light to etch designs and markings onto various materials, including metal. It’s a process where the laser beam acts as a chisel, incising fine lines with precision and speed. This technology is highly valued for its accuracy, allowing for intricate designs that traditional methods can’t achieve.

The flexibility of laser engraving is remarkable, catering to a wide range of applications from industrial marking to personalized items. Additionally, its non-contact nature ensures minimal wear and tear on tools, making it a cost-effective solution for long-term use. I’ve always been fascinated by how a beam of light can artfully transform a simple metal surface into a work of art.

2. Materials and Metals Suitable for Laser Engraving

After exploring the fundamentals of laser technology in engraving, it’s crucial to understand the specific materials and metals that are best suited for this process. Below are the key materials and metals suitable for laser engraving:

Stainless Steel

Known for its durability and resistance to corrosion, stainless steel is ideal for high-quality, permanent engravings. This makes it a top choice for industrial and commercial applications. Its sleek appearance provides an upscale look, enhancing the aesthetics of engraved items. I’ve always admired how stainless steel engravings add a touch of sophistication to any product.

Aluminum

Lightweight yet strong, aluminum is perfect for laser engraving when you need detailed, precise markings. Its ability to absorb laser energy efficiently results in clear, sharp engravings. This metal is particularly suitable for applications where weight is a concern, such as aerospace and automotive industries. The final product is not only visually appealing but also durable.

Brass

Brass, with its distinctive color and finish, is favored for decorative engravings, especially for its elegant golden tone that enhances awards and plaques. This increasing demand is reflected in the market trends; according to Wicz, the global Brass Rods market is projected to grow at a 3.56% CAGR, reaching USD 21,797.18 million by 2028, indicating a rising interest in brass for various applications.

Copper

Copper’s excellent conductivity and thermal properties make it suitable for detailed engravings, often used in electrical components and decorative items. The warm, reddish tone provides a striking backdrop for engravings, making them stand out. Copper is also known for developing a unique patina over time, adding a vintage appeal to engraved pieces.

Titanium

This metal is favored for its strength-to-weight ratio and corrosion resistance, making it suitable for both industrial and artistic laser engraving applications. Its ability to withstand extreme environments makes it ideal for outdoor and marine applications. Titanium’s distinctive silver-gray color provides a modern and sophisticated look for engraved items.

3. Design and Artistry in Laser Engraving

Following our exploration of the best materials and metals, it’s essential to delve into the realm of design and artistry enabled by this technology. Below are key design aspects in laser engraving, emphasizing its intricate and stunning capabilities:

Customization and Personalization

Laser engraving allows for the creation of personalized items, from jewelry to bespoke gifts. This technique can capture even the most intricate designs, offering limitless possibilities for customization. It’s ideal for adding a personal touch to gifts, making each piece unique and memorable. The ability to tailor designs to individual preferences makes laser engraving particularly appealing for custom-made products.

Complex Patterns and Textures

With laser engraving, achieving complex patterns and textures on various surfaces becomes useful. This technology enables intricate graphics and textures, enhancing depth and detail in both decorative and functional designs. For instance, laser engraving can be used to produce detailed world maps on wooden surfaces, where each country’s borders and topographical features are accurately and beautifully depicted.

Artistic Detailing

This technology excels in adding fine artistic details to any project, whether it’s replicating a photograph on metal or crafting delicate filigree patterns on jewelry. The precision of laser engraving brings an artist’s vision to life with extraordinary clarity and finesse. It opens up new avenues for creativity, allowing for the replication of artworks and historical patterns with astounding accuracy.

Branding and Logos

For businesses, laser engraving is an effective tool for branding, allowing precise and consistent reproduction of logos and brand elements on products and promotional materials. It helps in creating a professional and polished look that enhances brand identity. The durability of laser-engraved logos ensures that branding remains intact and visible over time, making it a smart investment for long-term marketing.

Interactive and Kinetic Art

More than just static designs, laser engraving can be used to create interactive and kinetic art pieces, where the engraved elements play a role in the overall movement and interaction of the piece. This application pushes the boundaries of traditional art, inviting viewers to engage with the artwork in dynamic ways. It’s thrilling to see how laser engraving brings a new level of interactivity to art.

4. The Process of Laser Engraving on Metal Surfaces

After discussing the design and artistry of laser engraving, let’s move forward to understanding the actual process involved in laser engraving on metal surfaces. Below is the step-by-step process:

Step#1 Design Creation

The process begins with designing the image or text to be engraved. This is usually done using specialized software, which allows for precise control over the dimensions and details of the design. The design can range from simple text to complex images, depending on the project’s requirements. It’s always exciting to see a client’s vision take shape in this initial creative stage.

Step#2 Material Preparation

Before engraving, the metal surface is cleaned and prepared. This may include removing any coatings or debris to ensure a clean engraving surface. Ensuring the metal is free of imperfections is crucial for achieving a flawless engraving. Additionally, some metals may require a specific pre-treatment to optimize the engraving quality.

Step#3 Laser Configuration

The laser engraving machine is then set up. This involves configuring the laser’s power, speed, and focal length according to the type of metal and the complexity of the design. Proper configuration is key to achieving the desired depth and clarity in the engraving. It’s also essential for minimizing damage to the metal surface during the engraving process.

Step#4 Engraving Process

The laser then engraves the design onto the metal surface. The laser beam precisely removes layers of the material to create the desired pattern or text. The precision of the laser allows for detailed and accurate reproductions of the design. The engraving process is closely monitored to ensure consistency and quality throughout the operation.

Step#5 Cleaning and Finishing

After engraving, the metal is cleaned to remove any residue. Additional finishing processes, such as polishing, may be applied to enhance the appearance of the engraving. This step is essential for giving the engraved product a professional and refined look. Finally, a protective coating may be applied to preserve the engraving and prevent tarnish or wear.

Step#6 Quality Inspection

The final step involves inspecting the engraved item to ensure the design is accurately rendered and meets quality standards. This includes checking for any errors or imperfections to guarantee a high-quality final product. Zemetal meticulously inspect this process, ensuring each piece reflects their commitment to excellence in craftsmanship.

5. Advancements and Innovations in Laser Engraving

Following an understanding of the process, it’s essential to explore the recent advancements and innovations. These innovations have boosted laser engraving’s efficiency and versatility. Below are the notable advancements and innovations in laser engraving:

High-Precision Lasers

Recent advancements have led to the development of high-precision lasers that can create extremely fine details. These lasers can engrave at a much higher resolution, allowing for more intricate and detailed designs than ever before. The resulting engravings are not only more aesthetically pleasing but also provide greater legibility for small text or complex patterns.

3D Laser Engraving

The introduction of 3D laser engraving technology has enabled the creation of detailed three-dimensional images within materials. This technique adds depth and realism to engravings, opening up new possibilities for artistic and industrial applications. It allows for the production of items that are not just visually striking but also engaging.

Faster Processing Speeds

Innovations in laser technology have significantly increased processing speeds, allowing for quicker production without compromising on quality. This improvement is particularly beneficial for businesses that require high volume production. For example, it reduces turnaround time, enabling businesses to meet customer demands more efficiently.

Improved Software Integration

Advanced software solutions have been developed to seamlessly integrate with laser engraving machines. These software enhancements offer better control over the engraving process, including more precise adjustments and easier design modifications. They also enable more user-friendly interfaces, making the technology accessible to a broader range of operators.

Eco-Friendly and Safer Operations

There has been a push towards making laser engraving more eco-friendly and safer. This includes the development of lasers that consume less energy and produce less waste, as well as improved safety features to protect operators. These advancements not only benefit the environment but also enhance the workplace by reducing health risks.

6. Applications of Laser Engraving in Various Industries

After learning about the advancements, now let’s explore diverse applications of laser engraving in various industries. Below are the applications of laser engraving in various industries, demonstrating its wide-ranging impact:

Manufacturing Industry

In manufacturing, laser engraving is used for marking parts and products for identification and traceability. This includes serial numbers, barcodes, and logos, ensuring every item is uniquely identifiable. The accuracy and durability of laser engraving aids in quality control and deter imitation. Zemetal’s adoption of this technology underscores their commitment to excellence in product tracking and security.

Jewelry Making

Laser engraving has revolutionized jewelry design, allowing for intricate personalization and detailing on precious metals. Jewelers can create custom designs and inscriptions, adding a personal touch to each piece. This technique also allows for the replication of complex patterns and images on a variety of jewelry surfaces. It’s especially popular for creating unique wedding bands and commemorative pieces.

Medical Equipment

Engraving is crucial in the medical field for labeling instruments and devices. It ensures that vital information, such as measurements and identification codes, are permanently marked for safety and compliance. This permanence is essential for sterilization processes where other types of labels could degrade or wear off. Accuracy in such engravings is critical to ensure patient safety and procedural precision.

Automotive Industry

Laser engraving is used for creating durable and precise markings on automotive parts. This ranges from functional labeling to decorative engraving on car interiors and exteriors. It’s also employed in creating VIN numbers and other critical safety information that must remain legible over the life of the vehicle. Seeing the intricate details that laser engraving adds to vehicles always fascinates me, blending art with functionality.

7. Safety and Maintenance in Laser Engraving Operations

After exploring the applications of laser engraving in various industries, it’s crucial to focus on the safety and maintenance aspects of these operations. Below are safety and maintenance in laser engraving operations:

Regular Cleaning and Inspection

Regularly cleaning and inspecting the laser engraver is essential. Dust and debris can interfere with the accuracy of the engraving and potentially harm the machine’s mechanics. It’s also important to check for any signs of wear and tear that could affect the machine’s functionality over time. Keeping a consistent maintenance schedule helps in prolonging the life of the equipment and ensuring top-notch performance.

Training and Safety Protocols

Proper training for operators is crucial. They should be well-versed in safety protocols, such as wearing protective gear and understanding how to operate the machine safely. Continuous education and updates on safety practices are also important to keep up with technological advancements. I always emphasize the importance of safety training; it’s the key to ensuring a secure and efficient work environment.

This table outlines essential aspects of training and safety protocols for machine operators, emphasizing the importance of proper education and adherence to safety standards for a secure and efficient work environment.

| Aspect | Description | Importance |

| Protective Gear Training | Educating on the proper use of safety equipment | Crucial for preventing injuries |

| Safe Operation Procedures | Instruction on correct machine usage | Essential for minimizing accidents |

| Emergency Response Training | Preparedness for handling unexpected situations | Vital for ensuring quick response |

| Continuous Education | Regular updates on new safety practices | Key for adapting to technological advancements |

| Safety Compliance Monitoring | Regular checks to ensure adherence to protocols | Important for maintaining a safe work environment |

Routine Calibration

Laser engravers require routine calibration to maintain accuracy. This involves adjusting the laser for optimal performance and ensuring that engravings are consistently precise. Calibration should also be conducted after any repairs or modifications to the machine. Regular calibration checks are key in avoiding errors and maintaining the high quality of engravings.

Ventilation Systems

Adequate ventilation is necessary to dissipate any fumes or particles produced during the engraving process. Installing and maintaining effective ventilation systems protects the health of the operator and prevents buildup on the machine. Regular checks and maintenance of these systems are crucial to ensure they function effectively.

8. Future Trends in Laser Engraving

After examining the safety and maintenance of laser engraving operations, it’s intriguing to look ahead at the future trends shaping this field. Below are the anticipated future trends in laser engraving:

Integration with Artificial Intelligence (AI)

AI technology is expected to be increasingly integrated into laser engraving systems. This integration will enhance precision, allow for more complex design capabilities, and improve efficiency by automating many aspects of the engraving process. AI can also adapt engraving parameters in real-time based on material feedback, optimizing the process for each unique job.

Portable Laser Engravers

The development of compact, portable laser engravers is likely to continue. These devices will make laser engraving more accessible for small businesses and hobbyists, allowing for on-site engraving services and greater flexibility in use. Their portability also paves the way for innovative uses in various settings, from craft fairs to remote industrial sites.

Eco-Friendly Solutions

As environmental concerns grow, the trend towards more sustainable and eco-friendly laser engraving practices will gain momentum. This includes the development of energy-efficient machines and the use of environmentally friendly materials. I’m personally very excited about this shift, as it represents a significant step towards a more sustainable future in our industry.

Conclusion

In this comprehensive guide, we’ve journeyed through the versatile world of laser engraving, from its basic principles to future trends. It’s a powerful tool, equipping businesses and creatives with the knowledge to harness this technology effectively.

At Zemetal, we’re committed to bringing these advancements to your doorstep. Whether you’re starting out or looking to upgrade your operations, we have the solutions you need. Feel free to contact us.

Dive Deeper Into Our Resources

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.