Ever wondered why electrostatic paint is revolutionizing the metal fabrication industry? It’s all about its unparalleled adhesion and finish quality.

With years of expertise in metal fabrication, I understand the nuances of surface coatings.

Electrostatic paint stands out for its efficiency and durability. It does not only enhance the aesthetic appeal but significantly extends the life of metal products, making it a game-changer for businesses dealing in metal fabrication.

In this comprehensive guide, we will delve into the intricacies of electrostatic powder painting, exploring its benefits, applications, and best practices.

Keep reading to unlock the potential of electrostatic painting in your business.

1. Defining Electrostatic Powder Paint

Electrostatic powder paint stands out for its unique application process and exceptional finish quality. Unlike traditional liquid paint, it uses no solvents, resulting in a thicker, more consistent coating without drips or runs. This process not only enhances the finish but also contributes to environmental sustainability by reducing volatile organic compounds (VOCs).

Moreover, this technique offers remarkable durability and longevity. The paint forms a strong bond with the metal, providing excellent resistance to corrosion, heat, and impact. This resilience makes it a preferred choice for heavy-duty industrial applications, ensuring long-lasting protection and reduced maintenance costs.

2. Advantages Over Traditional Liquid Paints

Building on the definition of electrostatic powder paint discussed earlier, it’s evident that this innovative method offers several key advantages over traditional liquid paints. Here are three major benefits:

Superior Adhesion and Longevity

Electrostatic powder paint offers exceptional adhesion to metal surfaces. This enhanced adhesion ensures that the coating remains intact under various conditions, resisting the common issues of peeling and flaking that often plague liquid paints. At Zemetal, the longevity of this paint type not only maintains the aesthetic quality of the products but also provides prolonged protection against environmental elements.

Reduced Environmental Impact and Health Hazards

Unlike liquid paints that often contain harmful solvents, powder paint is solvent-free, leading to a drastic reduction in the emission of volatile organic compounds (VOCs). This reduction not only helps in preserving the environment but also ensures a safer working atmosphere for employees. The absence of toxic fumes and chemicals makes it a preferable option in industries prioritizing safety and sustainability.

This table outlines the environmental and health benefits of using powder paint compared to liquid paints, emphasizing its role in reducing VOC emissions and enhancing workplace safety.

| Benefit | Description | Impact on Environment and Health |

| Reduction in VOC Emissions | Solvent-free nature leads to lower VOC release | Minimizes air pollution and health risks |

| Safer Working Environment | Absence of harmful solvents ensures safer working conditions | Reduces health hazards for employees |

| Less Toxic Waste | Eco-friendlier disposal process | Lowers environmental contamination risks |

| Improved Air Quality in Production Areas | No toxic fumes during application | Enhances workplace air quality |

| Compliance with Environmental Regulations | Meets stringent environmental standards | Supports sustainability initiatives |

Enhanced Efficiency in Material Usage and Application

The efficiency of electrostatic powder paint is a game-changer in terms of material usage and application. For example, any overspray can be collected and recycled, offering a stark contrast to liquid paints where overspray results in direct waste. The quick drying and curing times associated with powder paints streamline the production process, allowing for faster throughput and increased productivity in manufacturing operations

3. Types of Electrostatic Powder Paint

After examining the advantages of electrostatic powder paint, it’s clear that this technology is adaptable for a variety of applications. Electrostatic powder paints cater to specific needs and environments. Here are three distinct types:

- Epoxy-Based Powder Coatings: Known for their superior chemical resistance and durability, epoxy-based coatings are ideal for indoor applications. They provide excellent hardness and corrosion resistance, making them suitable for machinery and industrial equipment.

- Polyester-Based Powder Coatings: These coatings are favored for their versatility and overall outdoor durability. Polyester-based powders are UV-resistant and maintain their color and gloss levels over time, making them perfect for outdoor furniture, automotive parts, and architectural applications.

- Acrylic-Based Powder Coatings: Acrylic powders are renowned for their exceptional clarity and gloss retention. They offer excellent weatherability and UV resistance, which makes them ideal for automotive exteriors and high-visibility consumer goods where aesthetic longevity is crucial.

4. Application Techniques and Equipment

Building upon the different types of electrostatic powder paint, each requires specific application techniques and equipment for optimal results. Here are the key techniques and equipment involved in the process:

Techniques

- Corona Charging: The most common technique, where the powder is charged using a high-voltage, low-amperage power supply. This method provides an even, thorough coating.

- Tribo Charging: In this method, the powder gains a charge through friction within the gun. It’s particularly effective for complex shapes and recesses.

- Fluidized Bed Application: Used for thicker coatings, the preheated part is dipped into a fluidized bed of powder, creating a smooth, heavy coating.

- Electrostatic Fluidized Bed: Combines fluidized bed and electrostatic spray techniques, ideal for coating objects with complex geometries and cavities.

Equipment

- Spray Guns: Essential for precision application, spray guns come in various designs to suit different coating requirements.

- Powder Hoppers: These containers hold and dispense the powder paint during the application process and play a key role in maintaining consistent flow.

- Curing Ovens: After application, the coated parts are placed in curing ovens where the powder is fused into a uniform, durable layer.

- Recovery Systems: These systems capture oversprayed powder for reuse, enhancing efficiency and reducing waste.

5. Color and Finish Options in Electrostatic Powder Paint

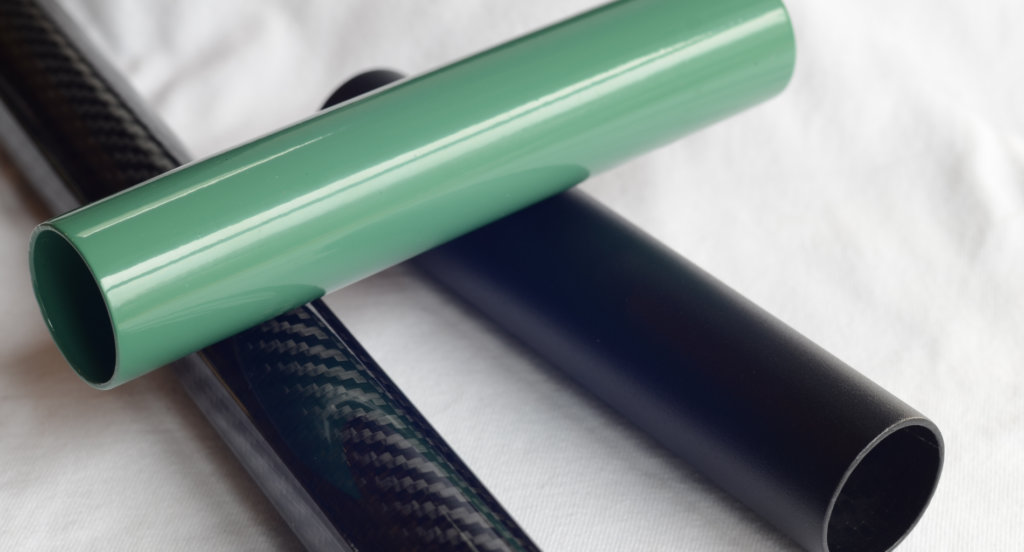

The versatility of electrostatic powder paint extends beyond application techniques and equipment, as demonstrated in its wide range of color and finish options. Here are the key options available in colors and finishes:

Color Variations

- Standard Colors: This range includes primary and secondary colors, providing versatility for general applications in industries from automotive to consumer goods.

- Custom Colors: Tailored to meet unique branding or aesthetic requirements, custom colors can be developed to match any specific shade or tone, ensuring brand consistency.

- Metallic and Special Effects: Offering a more dynamic appearance, these effects create visually striking finishes, ideal for high-end products or where a distinctive look is desired.

Finish Types

- Glossy Finishes: These finishes provide a bright, reflective surface, enhancing the visual impact and attractiveness of the product, especially in consumer-facing applications.

- Matte and Satin Finishes: Ideal for a modern and elegant look, these finishes minimize light reflection and are often used in premium products for their sophisticated appearance.

- Textured Finishes: Ranging from subtle to pronounced textures, these finishes not only add a tactile dimension but also help in disguising surface imperfections, making them practical for industrial and heavy-use items.

6. Applications in Various Industries

Following the exploration of the diverse color and finish options available in electrostatic powder paint, we see its practical applications across various industries. Below are some of these industries:

Automotive Industry

Electrostatic powder paint is widely used in coating vehicle parts, offering durability and corrosion resistance against harsh conditions. It’s also used for automotive accessories, ensuring longevity and aesthetic appeal. According to Yahoo Finance, the global Electrostatic Sprayers market is projected to grow at a 5.49% CAGR, reaching USD 78.73 million by 2028, highlighting the increasing demand for this technology.

Electronics and Appliances

Electrostatic powder paint is ideal for coating various electronic device casings, providing a durable, scratch-resistant surface. In appliances, from refrigerators to washing machines, the paint offers an aesthetically pleasing finish with the added benefit of being easy to clean and maintain. At Zemetal, we recognize that this adaptability in both color and finish ensures that the products meet both functional and design specifications.

Architectural Applications

In architecture, electrostatic powder paint is used for window frames, railings, and exterior panels, providing a long-lasting finish that can endure varying climatic conditions. This application not only enhances the visual appeal of structures but also contributes to their longevity and sustainability.

7. Electrostatic Powder Paint vs. Traditional Methods

The comparison between electrostatic powder paint and traditional painting methods is crucial, according to Precision Dip Coating, especially after considering the wide-ranging applications of the former. Here are some detailed contrasts:

Cost-Effectiveness and Material Usage

Electrostatic powder paint significantly edges out traditional methods in terms of cost-effectiveness and material usage. This method’s ability to recycle excess powder ensures minimal wastage, a stark contrast to liquid paints where overspray often results in direct material loss. Additionally, the extended lifespan of powder coatings, owing to their superior durability, means less frequent need for reapplication.

Application Speed and Productivity

The curing time for powder paint is generally quicker compared to the drying time for liquid paint. This speed is not just about saving time; it enhances overall productivity, especially in high-volume manufacturing environments. This rapid processing capability allows businesses to meet tight deadlines and increase throughput, a critical factor in maintaining competitive advantage in fast-paced markets.

Versatility in Aesthetic Options

Electrostatic powder paint provides a broader spectrum of color choices and the capability for more intricate and specialized finishes, like smooth textures, metallic sheens, and matte appearances. This versatility extends to achieving uniform coverage on complex shapes and surfaces, where liquid paints may struggle to provide consistent quality without runs or sags.

8. 4 Factors to Consider When Choosing Electrostatic Powder Paint

Following the comparison with traditional painting methods, it’s clear that electrostatic powder paint is a superior choice. However, selecting the right type of powder paint for specific applications requires careful consideration. Here are the crucial elements to evaluate:

#1 Intended Application and Environment

The intended use and the environmental conditions where the product will be exposed are pivotal in choosing the right powder paint. For indoor applications, epoxy-based powders are a prime choice due to their durability against chemicals and abrasions. On the other hand, for outdoor applications, polyester-based powders are more suitable because of their enhanced UV resistance and ability to withstand weather elements.

#2 Color and Finish Requirements

Standard color options offer a broad range for general applications, but specific projects might necessitate custom colors for branding or design purposes. Similarly, the finish—whether glossy for a shiny, eye-catching appearance, matte for a sophisticated, non-reflective surface, or textured for a unique tactile experience, can significantly impact the product’s appeal and functionality.

#3 Durability and Performance Needs

Evaluating the durability and performance needs of the powder paint is crucial. For instance, for environments prone to high levels of wear and tear, selecting powder paint that offers robust resistance to chipping, scratching, and corrosion is vital. This not only maintains the aesthetic integrity of the product but also ensures its longevity, reducing the need for frequent maintenance or replacements.

#4 Cost and Efficiency Considerations

Cost and efficiency are also paramount in the decision-making process. It’s important to consider the overall cost implications, including potential savings in maintenance and the need for reapplication. An analysis of these costs against the benefits and efficiencies of the chosen powder paint type will facilitate a more economically sound decision.

Conclusion

As we’ve explored, electrostatic powder paint offers a lot of advantages for metal fabrication businesses. Its ability to enhance durability, coupled with environmental benefits and cost-effectiveness, makes it a valuable addition to any fabrication process.

For those looking to integrate this cutting-edge solution into their operations, Zemetal offers expert metal fabrication services. Embrace the future of fabrication with our innovative approaches and customized solutions. Contact us today.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.