Are you curious about the shimmering finish on your favorite metal products? This marvel is the work of electroplating, a transformative process essential to metal fabrication.

With years of experience in the industry, we understand the intricacies of electroplating and its impact on your business.

Electroplating stands as a cornerstone in metal fabrication, merging aesthetic appeal with functional excellence. Understanding its definition and applications is crucial for enhancing business quality and performance.

In this guide, we’ll cover the essentials and the complexities of electroplating, providing you with the knowledge needed to leverage this technique for the betterment of your metalworks.

Read on to delve deeper into the world of electroplating.

1. Overview of Electroplating

Electroplating, which applies a thin metal layer onto another via electric current, enhances properties like corrosion and wear resistance, as well as aesthetic appeal. Its significance is evident across industries such as automotive and jewelry, where it provides customization and durability.

Notably, the market for electroplating is on a robust growth trajectory, expected to exceed US$ 30 billion by 2033 as highlighted by FMI. This data underscores the critical and expanding role of electroplating in efficiently meeting technical specifications and consumer demands within modern manufacturing and product development.

2. Benefits of Electro Nickel Plating

Building on the foundation of electroplating’s importance, let’s delve into the specific advantages of Electro Nickel Plating, a process esteemed for its unique properties and wide-ranging applications:

Corrosion Resistance

Electro Nickel Plating provides an exceptional barrier against corrosion, significantly extending the service life of metal components. This protection is crucial in environments prone to rust and degradation, ensuring consistent performance and reducing maintenance needs.

Electro Nickel Plating, renowned for its corrosion resistance, plays a pivotal role in enhancing the durability of metal components. Below is a table summarizing its key aspects:

| Aspect | Description |

| Corrosion Resistance | Provides a strong barrier against environmental degradation. |

| Service Life Extension | Increases the longevity of metal components in various industries. |

| Reduced Maintenance | Lowers the frequency and cost of upkeep due to enhanced durability. |

| Consistent Performance | Ensures reliable functionality in corrosive environments. |

| Application Versatility | Suitable for a wide range of industrial and consumer products. |

Uniform Coating

Electro Nickel Plating excels in creating a uniform and smooth layer across the entire surface of metal parts, regardless of their complexity. This uniform coating is crucial for detailed components, ensuring thorough protection and enhancement throughout. For example, in the automotive sector, uniform coating is key for parts such as gears and pistons, where consistent coverage ensures peak performance.

Versatility in Applications

Electro Nickel Plating is not limited to a single industry or application.Its versatility is evident as it caters to aerospace, automotive, and consumer electronics, among others. This adaptability makes it a preferred choice for businesses looking to improve their product range with a reliable and high-quality finish.

3. Types of Electroplating

Electroplating is not a one-size-fits-all solution; it encompasses a variety of methods tailored to specific needs. Let’s explore the different types of electroplating and how each one serves a unique purpose in the industry:

Gold Plating

Gold plating is sought after for its exceptional conductivity and resistance to corrosion. It’s frequently used in electronics to ensure reliable signal transmission. For example, most high-quality audio connectors are gold plated to maintain superior sound quality.

Silver Plating

Silver plating is renowned for its high electrical conductivity and thermal conductivity, making it ideal for electrical and heat transfer applications. Its use in high-performance batteries and radiators underscores the practicality and effectiveness of this type.

Nickel Plating

Nickel plating is favored for its hard, wear-resistant surface and its ability to add a lustrous sheen to metal parts. This type is commonly used in automotive components and household fixtures, providing both aesthetic appeal and a protective barrier against corrosion and wear.

4. The Electroplating Process

Having outlined the various types of electroplating, understanding the underlying process is key to appreciating how different metals are applied. Here’s a breakdown of the fundamental steps involved in the electroplating process:

Step#1 Preparation of the Surface

Firstly, before any electroplating can occur, the surface of the substrate must be thoroughly cleaned and prepared. This typically involves degreasing, rinsing, and sometimes etching to ensure that the metal surface is free from contaminants that could interfere with adhesion.

Step#2 Pre-treatment

Secondly, pre-treatment involves preparing the surface for electroplating. This may include etching, striking, or other processes designed to ensure the metal is ready to accept the plating material. This step is crucial for achieving a strong bond between the substrate and the plating layer.

Step#3 Electrolyte Preparation

Next, the electrolyte solution containing the metal to be plated, is carefully prepared. The composition and pH of this solution are critical for the quality of the plating. It’s fascinating to see how precise this mixture needs to be to ensure a perfect finish.

Step #4 Actual Plating

In this step, the substrate is submerged in the electrolyte solution, and an electric current is applied. This causes the metal ions from the solution to adhere to the substrate, forming a thin, uniform coating over the entire surface.

Step#5 Post-treatment

After plating, post-treatment processes such as rinsing, drying, and polishing are performed. These steps are essential for enhancing the appearance of the plated item and ensuring its surface is free from any residues or imperfections.

5. Applications of Electroplating

Electroplating’s versatility allows it to meet the specialized needs of various industries. Here, we will shed light on the specific applications in different sectors where electroplating plays a pivotal role:

Jewelry and Fashion Industry

In the jewelry and fashion industry, electroplating is used to coat pieces with precious metals like gold and silver, enhancing their appearance and value. This process ensures that accessories remain lustrous and resistant to tarnishing over time, keeping them beautiful and durable.

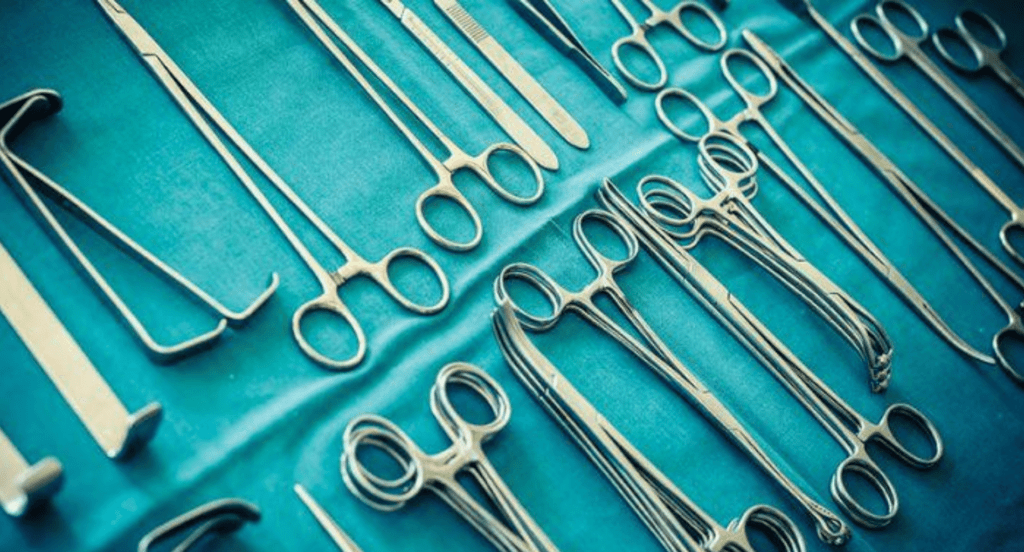

Medical Industry

In the medical industry, electroplating is particularly crucial for surgical instruments and implants. It enhances the tools’ resistance to corrosion and wear, ensuring they remain sterile and functional over repeated use. This process is vital for patient safety and the longevity of medical equipment, directly impacting the success and reliability of medical procedures.

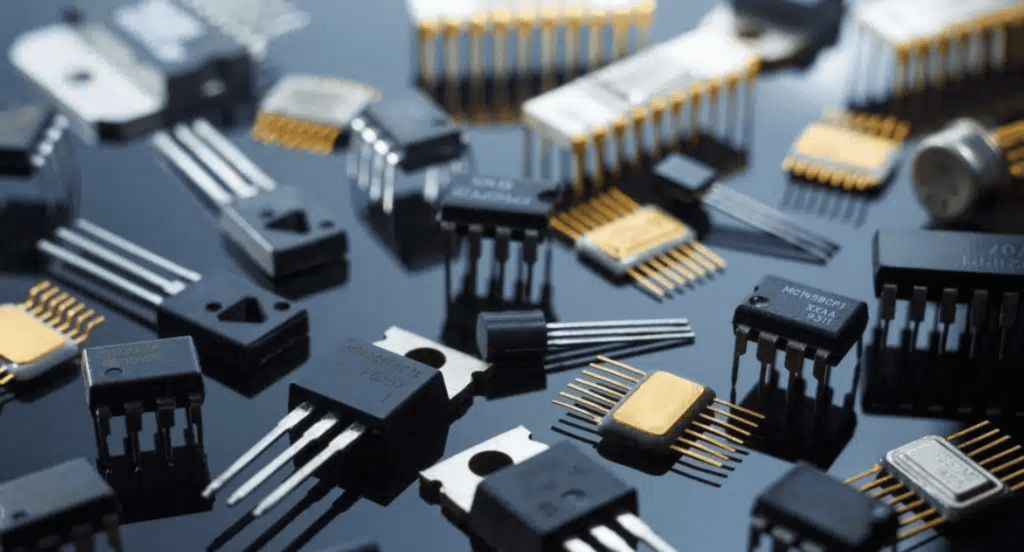

Electronics Industry

The electronics industry relies heavily on electroplating for its superior conductivity and protective qualities. Components like connectors, switches, and circuit boards are often plated with gold or silver to ensure efficient and reliable performance. This attention to detail is crucial in an industry where precision is paramount.

6. Advancements and Innovations in Electro Nickel Plating

The realm of electro nickel plating is continuously evolving, driven by technological innovation and a commitment to excellence. Here are some cutting-edge advancements reshaping the future of this vital industrial process:

Pulse Plating Technology

Pulse plating technology represents a significant leap forward, using periodic pulses of current to achieve more uniform and dense coatings. This method enhances the physical properties of the nickel layer, offering superior protection and finish compared to traditional plating techniques.

Direct Laser Deposition

The advent of direct laser deposition has introduced a precise method for adding nickel coatings. This technology allows for the direct application of nickel onto specific areas, providing targeted enhancement with minimal waste. It’s impressive to witness how such precision can lead to significant material and cost savings.

High-Speed Plating Solutions

High-speed electro nickel plating solutions have transformed production capabilities, drastically reducing the time required for the plating process. These advancements not only increase throughput but also maintain the high-quality standards expected in the industry, making them a game-changer for businesses looking to scale up their operations.

7. Troubleshooting Common Issues in Electro Nickel Plating

While advancements in electro nickel plating have been substantial, challenges still arise. Understanding how to troubleshoot these issues is key to maintaining quality and efficiency. Here are some common problems and their solutions:

Blistering and Peeling

Blistering or peeling of the nickel layer is often due to trapped gases or moisture. Ensuring a proper pre-plating treatment, including thorough degreasing and decontamination, can prevent these issues. Adjusting the current density and temperature can also enhance the plating bond strength, reducing the risk of blistering.

Pitting and Pinholes

Pitting or pinholes usually result from trapped air bubbles or particulate matter. Employing agitation systems like air or mechanical stirring in the plating bath helps release trapped gases and distribute particles evenly. Zemetal utilizes advanced filtration to maintain bath purity, significantly minimizing the occurrence of pitting and pinholes.

Dull or Cloudy Finishes

A dull or cloudy finish can detract from the aesthetic appeal of nickel-plated items. This issue is often related to low brightness levels in the plating solution or inadequate rinsing. Optimizing the chemical composition of the plating bath and thorough rinsing restores luster and clarity to the finished product. Regular maintenance and quality checks are key to achieving and sustaining high-quality finishes.

8. 3 Practical Tips for Effective Electroplating

Effective electroplating demands attention to detail and adherence to best practices. Here are some additional practical tips to ensure that the electroplating process is as efficient and high-quality as possible:

#1 Regular Equipment Checks

Frequent inspections and maintenance of electroplating equipment are vital. Ensure that all apparatus, from anodes to tanks, are in optimal condition to prevent defects. This includes checking for wear and tear, ensuring electrical connections are secure, and that there are no leaks or contamination.

#2 Adequate Surface Preparation

Proper surface preparation is key to achieving strong adhesion and flawless finishes. Ensure that substrates are thoroughly cleaned, degreased, and free from oxidation before plating. Zemetal emphasizes meticulous surface preparation, recognizing that this fundamental step significantly influences the final quality of the electroplated product.

#3 Employee Training and Safety

A well-trained team is crucial for effective electroplating. Ensuring that all personnel are knowledgeable about the process and safety protocols not only promotes a healthier work environment but also improves the quality of the output. Regular training updates and safety drills contribute significantly to the overall success and efficiency of the electroplating process.

Conclusion

This guide has journeyed through the essential aspects of electroplating, providing you with the knowledge to improve both the quality and efficiency of your metal fabrication processes. With these insights, you’re set to make informed decisions that will enhance your business operations.

Turn to Zemetal for all your electroplating needs. Explore our services and discover how we can assist in elevating your projects. For more information or to get in touch with our expert team, contact us today.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.