Why choose between chrome plating vs zinc plating for metal fabrication needs? Each method offers unique benefits tailored to different applications.

As a specialist in metal fabrication services, we understand the nuances of these finishes and their impact on the products.

Chrome plating provides a glossy finish and superior corrosion resistance, whereas zinc plating offers protective qualities and is more cost-effective.

In this article, we delve into the specifics of each plating type, providing insights to assist in making informed business decisions.

Discover the ideal metal finish for each projects – keep reading to learn more.

1. Brief Overview of Metal Plating and Its Importance

Metal plating is a process where a thin layer of metal is applied to a surface. This method not only enhances the appearance of the item but also boosts its resistance to corrosion, wear, and tarnish. Additionally, it can improve electrical conductivity, making it vital in electronic components. It’s like giving your metals a durable yet stylish coat!

The significance of metal plating extends beyond aesthetics; it plays a crucial role in industries such as automotive, electronics, and aerospace. According to LinkedIn, the global Metal Plating and Finishing market is expected to grow from USD 16,160 million in 2023 to USD 21,190 million by 2030, at a 3.9% CAGR. This growth highlights how essential metal plating is in our daily lives and various industries.

2. Understanding Chrome Plating

Chrome plating involves applying a layer of chromium to a metal surface through electroplating. This technique enhances the visual appeal and significantly increases the metal’s durability. Additionally, it provides a smooth, easy-to-clean surface that resists tarnishing. It’s like giving metal a makeover for both beauty and strength!

Benefits of Chrome Plating:

- Aesthetic Appeal: Provides a bright, mirror-like finish, making it a favorite for decorative purposes and adding visual interest to any product. For instance, this lustrous appearance is particularly valued in consumer-facing products.

- Corrosion Resistance: Offers strong protection against rust and deterioration, crucial for products exposed to harsh environments. This makes it an ideal choice for outdoor or marine applications.

- Increased Durability: Enhances the lifespan and wear resistance of the metal, ideal for components subject to frequent use and wear. This results in lower replacement costs over time.

- Ease of Cleaning: Smooth surfaces allow for easy maintenance and cleaning, contributing to the longevity and sustained appearance of products. Its low upkeep is a key advantage for high-traffic items.

Applications of Chrome Plating:

- Automotive Industry: Used in car parts like bumpers, rims, and grills, enhancing vehicle durability and aesthetic appeal. It’s especially popular in custom and luxury car markets.

- Home Fixtures: Applied in faucets, door handles, and lighting fixtures, providing a touch of elegance and resistance to daily wear and tear. Chrome plating is often chosen for its modern, sleek look in home decor.

- Tools and Hardware: Utilized in hand tools, machinery parts, and hardware, ensuring a longer lifespan and resilience under continuous use. This is critical in industrial and construction settings.

- Decorative Items: Popular for creating shiny, decorative finishes on various objects, offering an eye-catching enhancement to any item. Its use ranges from jewelry to art installations.

3. Exploring Zinc Plating

Zinc plating involves coating metal with a layer of zinc, typically through electroplating. This method is essential for preventing rust and enhancing the durability of metal parts. Additionally, it forms a sacrificial layer, which rusts over time, protecting the underlying metal. It’s an invisible yet powerful protector for your metals!

Benefits of Zinc Plating

- Corrosion Resistance: Zinc plating greatly reduces rust and corrosion, enhancing the longevity of metal parts, and is particularly effective in humid environments.

- Cost-Effectiveness: This method is more economical compared to other metal finishes, offering a budget-friendly solution without compromising quality.

- Versatility: Zinc plating is adaptable, suitable for a variety of metals and diverse applications, making it a versatile choice for many industries.

- Improved Conductivity: It improves electrical conductivity, making it valuable for electronic components, and is also ideal for reducing electromagnetic interference.

Applications of Zinc Plating

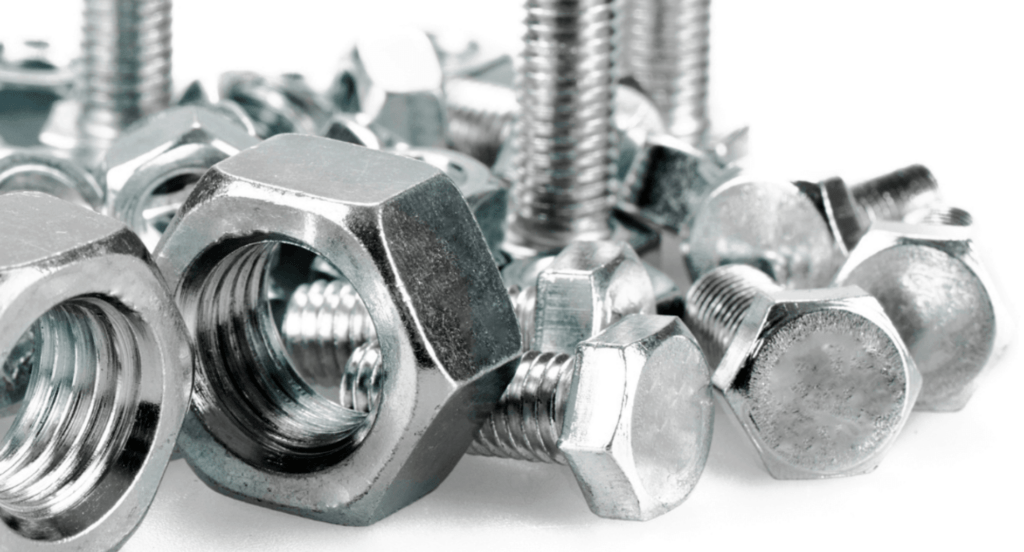

- Construction Materials: Zinc is used in items like fasteners and structural steel, providing strength and resilience against environmental wear.

- Automotive Components: It’s commonly found in under-the-hood parts, helping resist environmental and thermal stress, and is essential for vehicle longevity.

- Electronics: Zinc plating is used in electrical connectors and circuit boards, aiding in efficient conductivity and preventing corrosion in electronic devices.

- Marine Equipment: Ideal for metal parts in marine environments, it protects against water-induced corrosion, ensuring the durability of marine hardware and equipment.

4. Comparative Analysis: Chrome Plating vs Zinc Plating

After examining the details of zinc plating, it’s time to compare it with chrome plating. This comparative analysis will highlight the distinct features and advantages of each method. Below are the essential aspects of the comparative analysis:

Visual Appeal and Finish

Chrome plating is known for its high-gloss, mirror-like finish, offering a luxurious and eye-catching appearance, while zinc plating provides a more subtle, matte look, preferred for its understated elegance. This difference significantly influences the choice based on aesthetic requirements, catering to different stylistic preferences. It’s all about the visual impact!

Corrosion Resistance

While both provide corrosion resistance, chrome plating offers a higher level of protection, especially against harsh conditions such as saltwater exposure and industrial chemicals. Zinc plating, however, is more suitable for general protection in less aggressive environments and acts as a sacrificial layer, corroding itself to protect the underlying metal.

Durability and Wear Resistance

Chrome plating typically offers greater durability and resistance to wear, making it ideal for high-impact applications such as automotive exteriors and heavy machinery. It maintains its integrity even under extreme stress and frequent use. For instance, zinc plating, while durable, is better suited for moderate wear conditions and is often used in less demanding applications like household fixtures and general hardware.

Chrome and zinc plating serve distinct purposes in varied applications, as outlined in the table below.

| Application | Chrome Plating | Zinc Plating |

| Automotive Exteriors | Ideal for high-impact applications, offering superior durability. | Suited for moderate wear conditions in less demanding applications. |

| Heavy Machinery | Maintains integrity under extreme stress and frequent use. | Used in applications where moderate durability is sufficient. |

| Household Fixtures | Less commonly used due to its durability and cost. | Often utilized for general hardware and fixtures. |

| General Hardware | Rarely employed due to its high durability and cost. | Well-suited for less demanding applications due to moderate durability. |

| Marine Equipment | Provides exceptional durability against harsh marine conditions. | May be used in certain marine applications with lower wear demands. |

Cost and Economic Viability

Zinc plating is generally more cost-effective than chrome plating, making it a preferred choice for large-scale or budget-sensitive projects. Its lower cost also allows for more frequent replacements if necessary, without significantly impacting overall expenses. Conversely, chrome plating, while more expensive, offers a long-term investment in durability and aesthetics, justifying its higher initial cost for premium applications.

Environmental Impact and Safety

Both plating methods have different environmental impacts, with chrome plating requiring more stringent safety measures due to its chemical composition. Zinc plating, in contrast, is often viewed as a more environmentally friendly option. Zemetal is actively researching innovative techniques to further minimize the environmental footprint of both processes.

5. 5 Factors to Consider When Choosing Between Chrome and Zinc Plating

After our comparative analysis, it’s clear that choosing between chrome and zinc plating depends on various factors. Below are the key factors to consider when choosing between chrome and zinc Plating:

#1 Budget Constraints

If cost is a major concern, zinc plating is more budget-friendly and ideal for high-volume or less visually critical applications. However, for projects where quality and aesthetics are paramount, the higher cost of chrome plating can be a worthwhile investment, especially for premium or luxury items. Remember, the best choice balances cost with the desired outcome of your project.

#2 Maintenance and Longevity

Evaluate the maintenance needs and expected lifespan of the plated item. Chrome plating typically requires less maintenance and lasts longer, making it ideal for items not frequently replaced, such as luxury car parts or high-end bathroom fixtures. These items benefit from the long-lasting durability and reduced upkeep of chrome plating.

#4 Size and Complexity of the Item

Larger or more complex items may benefit more from zinc plating due to its cost-effectiveness and easier application process, making it a preferred option for bulk manufacturing or large machinery. Chrome plating, on the other hand, is better for smaller or more detailed items where the finish is a critical aspect, such as in decorative elements or high-end consumer products.

#5 Production Volume and Speed

For high-volume production, zinc plating can be more efficient and cost-effective, particularly suitable for manufacturing large quantities of industrial components or hardware. Chrome plating is ideal for smaller, high-quality production where a superior finish is key, like in custom automotive or luxury goods manufacturing. Zemetal excels in providing tailored solutions to meet these specific plating needs for various industries.

Conclusion

In conclusion, understanding the differences between chrome and zinc plating is crucial for making informed decisions in metal fabrication. This guide aims to help businesses, like yours, choose the right plating method based on specific needs and project requirements.

If you’re seeking expert advice or quality plating services, Zemetal is here to assist. For further information or to discuss your project needs, feel free to contact us.

Dive Deeper Into Our Resources

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.