Are you constantly striving to enhance the durability and appearance of your metal products? As business owners in the competitive market, understanding the distinction of metal finishes is a game-changer.

As an expert in the metal fabrication industry, I bring years of experience and a deep understanding of the well-known metal finishes. My insights are grounded in practical applications ensuring you receive information that’s reliable and relevant.

Chrome plating offers a distinctive shiny finish, while powder coating is known for its durability and diverse color options. Both have their own set of characteristics that make them suitable for different applications.

In this guide, we’ll delve into the technicalities, benefits, and ideal use-cases of chrome plating and powder coating. You’ll learn how to choose the right method based on your specific business needs and the type of product you’re handling.

Read on to uncover the intricacies of these metal finishing techniques.

1. Brief Overview of Metal Finishing Techniques

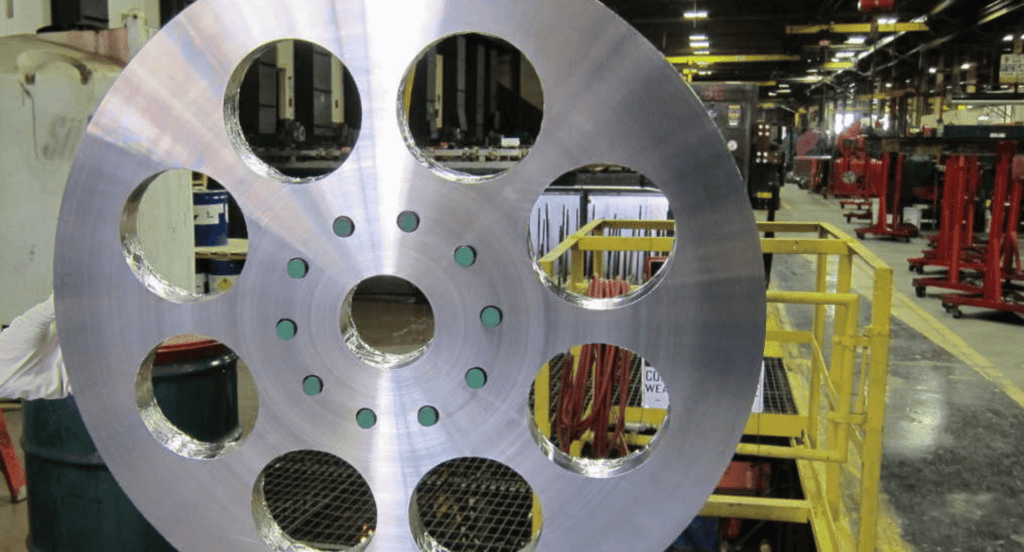

Metal finishing is an essential process in metal fabrication, employed to enhance the surface of metal products. This technique not only improves the appearance but also increases the durability, resistance to corrosion, and overall performance of the metal. Common methods include plating, coating, and polishing, each providing different aesthetic and functional benefits suited to various applications.

The choice of finishing technique depends on the desired outcome and the specific properties required for the end product. Factors such as environmental exposure, wear resistance, and visual appeal play significant roles in determining the appropriate finishing method. Understanding these techniques is crucial for fabricators like Zemetal in delivering products that meet both aesthetic standards and functional demands.

2. Understanding Chrome Plating

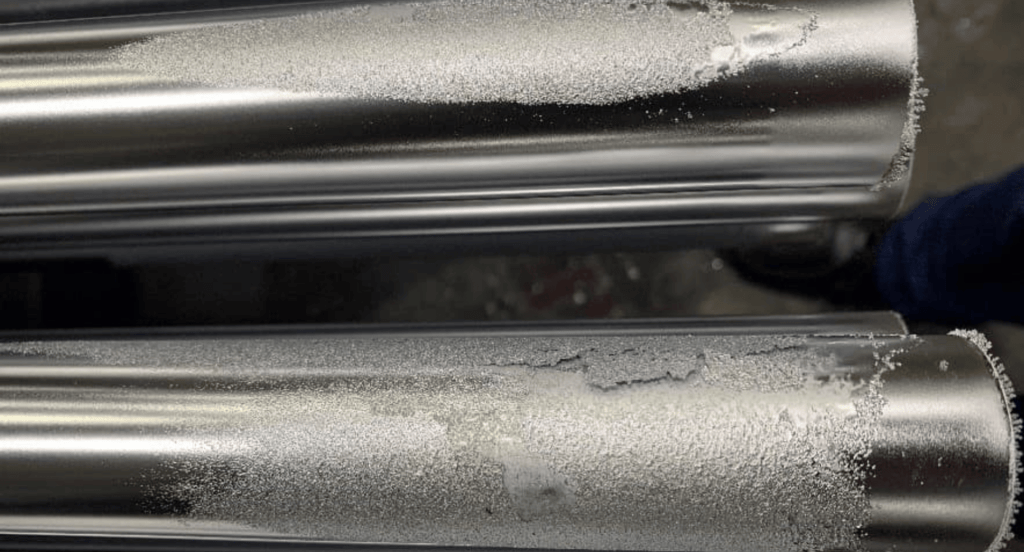

Chrome plating is a process where a thin layer of chromium is electroplated onto a metal or plastic object. This technique enhances the object’s hardness and aesthetic appeal, providing a shiny, mirror-like finish. The process involves several steps, including cleaning, etching, and finally, depositing the chromium layer onto the substrate.

Types

- Decorative Chrome Plating: Decorative chrome plating is primarily used for aesthetic purposes, providing a reflective finish. This type involves a thin chromium layer applied over nickel or copper base coats, enhancing corrosion resistance. It’s commonly seen on car parts, household fixtures, and hardware.

- Hard Chrome Plating: Hard chrome plating is utilized for its durability and wear resistance. It involves applying a thick layer of chromium to industrial equipment, tools, and machinery parts. This type enhances the life of equipment by reducing friction and improving resistance to heat and chemicals.

- Flash Chrome Plating: Flash chrome plating is a thinner version of chrome plating, often used as an undercoat for decorative chrome or in applications where only slight corrosion resistance is needed. It’s quicker and less expensive than other methods but provides a less durable finish.

- Black Chrome Plating: Black chrome plating offers a sleek, semi-glossy black finish, often used for optical and architectural applications. It provides the same protective qualities as traditional chrome plating but with a unique aesthetic appeal. This type is popular for instruments, photography equipment, and lighting fixtures due to its light-absorbing characteristics.

Applications

- Automotive Industry: In the automotive sector, chrome plating is used for functional and decorative purposes. Components like bumpers, rims, and engine parts are often chrome-plated for enhanced aesthetics and corrosion resistance. Zemetal provides chrome plating services that meet the high standards required in the automotive industry.

- Aerospace Industry: The aerospace industry utilizes chrome plating for critical components such as landing gears, control systems, and hydraulic pistons. The high wear resistance and reduced friction provided by chrome plating are vital for the safety and efficiency of aircraft operations.

- Manufacturing Tools and Machinery: In manufacturing, tools and machinery components are frequently subjected to heavy use and harsh environments. Chrome plating is applied to increase the lifespan and performance of these components. It reduces the need for frequent replacements, thereby minimizing downtime in production processes.

Benefits

- Enhanced Durability: According to SNS Insider, the chrome plating market is expected to reach USD 24.03 billion by 2030. This growths impact the chrome plating’s hard surface resistant to wear and tear, significantly extending the lifespan of products in various industries, aligning with the market’s substantial growth and the increasing demand for durable finishes.

- Improved Corrosion Resistance: Chrome plating acts as a barrier against corrosion, protecting the base material from rust and oxidation. This is crucial in environments where parts are exposed to moisture, chemicals, and varying temperatures. By preventing corrosion, chrome plating ensures the longevity and reliability of the components.

- Aesthetic Appeal: The glossy and reflective finish of chrome plating adds a premium look to any object. This visual enhancement is a key reason for its popularity in decorative applications. The ability to maintain its luster over time also means that products retain their aesthetic appeal for longer.

- Low Maintenance: Chrome-plated surfaces are easy to clean and maintain. They resist dirt and stains, requiring only a simple wipe to restore their shine. This ease of maintenance, coupled with their durability, makes chrome plating a cost-effective solution for both industrial and decorative applications.

3. Exploring Powder Coating

Powder coating is an advanced finishing process that involves applying a dry, powdered paint compound made of pigments, polymer resins, curatives, leveling agents, and other additives. Unlike traditional liquid paint, it’s applied electrostatically and then cured under heat to form a durable, protective skin over the material. This method is favored for its environmental friendliness, as it emits fewer volatile organic compounds (VOCs).

Types

- Epoxy Powder Coating: Known for its excellent adhesion, chemical and corrosion resistance, epoxy powder coating is typically used in indoor applications. It provides a durable finish making it ideal for coating machinery, automotive parts, and household appliances.However, it can be prone to chalking and fading when exposed to prolonged UV light.

- PolyesterPowder Coating: Polyester coatings are popular due to their overall balance of chemical, mechanical, and UV resistance. They are widely used for coating metal frames, outdoor furniture, and automotive components. Polyester powder coatings are available in a vast range of colors and gloss levels.

- PolyurethanePowder Coating: This type provides enhanced resistance to corrosion, chemicals, and UV light. Polyurethane powder coatings have a smoother finish than epoxies and are often used on top of a primer to coat a variety of surfaces including vehicles, outdoor furniture, and architectural structures.

- AcrylicPowder Coating: Acrylic coatings offer outstanding gloss and a smooth finish, along with good color retention and overall weatherability. They are often used for automotive parts and other exterior applications where aesthetics are particularly important. Acrylics provide a hard shell and are less prone to chipping, making them ideal for high-impact environments.

Applications

- Automotive Industry: In the automotive realm, powder coating is used for coating wheels, bumpers, frames, and other parts. It provides a durable, corrosion-resistant finish that can withstand the rigors of daily use and harsh weather, making it ideal for both functional and decorative automotive components.

- Architectural and Building Sector: Powder coating is extensively used in the architectural field for coating aluminum extrusions used in window frames, door frames, and building facades. Its ability to resist weathering and maintain color and gloss over extended periods makes it a preferred choice for both interior and exterior applications.

- Furniture Manufacturing: Both outdoor and indoor furniture benefit from powder coating’s durability and aesthetic finish. It’s especially popular for metal furniture used in public and commercial spaces because it can withstand heavy use and maintain its appearance over time.

- Appliance Industry: Powder coating is widely used in the home appliance sector for coating refrigerators, washer tops and lids, dryer drums, and air conditioner cabinets. It provides a durable, attractive finish that resists scratching, chipping, and fading, ensuring the appliances stay looking new for longer.

Benefits

- Environmental Friendliness: Powder coating emits negligible volatile organic compounds (VOCs), making it a more environmentally friendly option than traditional liquid paints. Its ability to be recycled and reused during the application process also minimizes waste.

- Durability and Longevity: Powder coating provides a thick, uniform coating that’s highly resistant to chipping, scratching, and corrosion. For example, outdoor furniture coated with powder paint can withstand harsh weather conditions and frequent use without losing its aesthetic appeal.

- Aesthetic Versatility: With a wide range of finishes, textures, and colors available, powder coating offers a high degree of customization. Whether you need a smooth, matte, or textured finish, powder coating can provide the desired look while maintaining its functional properties.

- Cost-Effective: Powder coating generally requires fewer touch-ups and maintenance over its lifespan compared to other finishes. Its efficient application process and minimal waste also contribute to cost savings, making it a cost-effective solution for a wide range of applications.

4. Key Difference of Chrome Plating and Powder Coating

After exploring the realms of chrome plating and powder coating, it’s clear that both methods offer unique advantages and applications. Let’s have a detailed discussion with its differences below:

Environmental Impact

- Chrome Plating: Chrome plating involves a series of chemical baths, with certain types using hexavalent chromium, a hazardous substance. Its process emits VOCs and requires careful handling and disposal of chemicals, making it less environmentally friendly.

- Powder Coating: Powder coating is known for its eco-friendly nature. It emits negligible VOCs and overspray can often be recycled, minimizing waste. The absence of hazardous chemicals in its application makes it a safer and more sustainable choice.

Heat Resistance

- Chrome Plating: Chrome plating has excellent heat resistance, maintaining its integrity and appearance even when exposed to high temperatures. This makes it suitable for parts that are regularly subjected to heat, such as engine components and exhaust systems.

- Powder Coating: While powder coating is generally resistant to heat, its tolerance is dependent on the type of powder used. Some powders may degrade or discolor at high temperatures, so it’s crucial to select the right formulation for heat-intensive applications.

Conductivity

- Chrome Plating: Chrome plating adds a conductive layer to the surface of the material, which can be beneficial for certain electrical and electronic applications. This conductivity can be crucial for components that require a seamless transfer of electricity.

- Powder Coating: Powder coating is typically non-conductive, which means it can act as an insulator for electrical components. This characteristic is particularly beneficial for parts that need to be protected from electrical interference or short circuits.

Thickness and Weight

- Chrome Plating: Chrome plating typically adds a very thin layer to the surface, which doesn’t significantly impact the weight or dimensions of the part. This can be particularly important in applications where weight and space are critical factors.

- Powder Coating: Powder coating tends to be thicker than chrome plating, which can add slight weight and increase the dimensions of the coated part.While this contributes to its durability, it may also be a consideration for projects where precise tolerances are required.

5. 4 Tips for Choosing Between Chrome Plating and Powder Coating

Navigating the key differences between chrome plating and powder coating is vital for making an informed decision. Here are variations of tips to help you choose the right finishing method for your needs:

#1 Consider the End-Use Environment

When selecting between chrome plating and powder coating, assess the environment in which the finished product will operate. Chrome plating is suited for items requiring a high level of reflectivity and heat resistance, often used in automotive and indoor decorative items. However, if the product will face rough conditions, powder coating’s superior resistance to corrosion and wear makes it a more durable choice.

#2 Evaluate Aesthetic Preferences

Your aesthetic requirements will significantly influence your choice. For instance, chrome plating offers a distinctive, mirror-like finish that stands out for its shine and is often chosen for its classic appeal in decorative applications. Powder coating, on the other hand, provides a wide range of colors and finishes, allowing for greater customization and versatility in matching specific design themes or corporate branding.

This table explores different aesthetic preferences and their impact on the choice of metal finishing techniques, such as chrome plating and powder coating, emphasizing their unique visual appeals.

| Aesthetic Preference | Description | Metal Finishing Technique |

| Mirror-like Shine | High gloss and reflective finish | Chrome Plating |

| Color Customization | Ability to match specific colors and themes | Powder Coating |

| Classic Appeal | Traditional and elegant look | Chrome Plating in Decorative Applications |

| Versatility in Finishes | Variety in texture and appearance | Powder Coating for Diverse Applications |

| Branding Compatibility | Aligning with corporate identity and branding | Powder Coating for Corporate Themes |

#3 Production Volume and Speed

Consider the scale and speed of your production when choosing between chrome plating and powder coating. For high-volume, fast-paced production, powder coating can be more efficient as it typically has a quicker turnaround time and allows for the coating of multiple items simultaneously. Chrome plating’s high quality finish is generally more time-consuming and may not be as suitable for rapid, large-scale production.

#4 Part Complexity and Size

The complexity and size of the parts you’re finishing can significantly influence the choice between chrome plating and powder coating. Chrome plating is ideal for intricate, detailed items as it can evenly coat complex surfaces and hard-to-reach areas. Powder coating, however, might be more challenging to apply uniformly on highly intricate parts but is excellent for larger, more straightforward items due to its curing process.

Conclusion

This guide has revealed the distinct advantages and considerations of chrome plating and powder coating, equipping you with the knowledge to make informed decisions. Understanding these differences is crucial in selecting the right finish for your metal fabrication needs.

If you’re seeking further guidance or wish to explore how these finishes can elevate your products, Zemetal is here to assist. Contact us today to discuss your specific needs and discover the best metal finishing solutions.

Dive Deeper Into Our Resources

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.