Chrome Plating Services

Dive into our selection of top-tier metal services, where unparalleled quality meets innovative design. Each item in our range is a testament to our commitment to excellence in metal fabrication.

Explore Our Premium Metal Fabrication Range

In the world of metal finishing and protection, Zemetal stands at the forefront, offering premier chrome plating service, chrome coating service, and chrome dipping solutions. Our expertise lies in transforming a variety of metal components with a durable, aesthetically pleasing chrome finish. Our services cater to a wide range of applications, ensuring longevity and resilience for your products.

We take pride in our state-of-the-art facilities and skilled team, dedicated to delivering high-quality chrome finishes that meet the most strict industry standards. We understand the importance of precision and quality in every project. Whether it’s for functional durability or enhancing appearance, our chrome plating processes are designed to provide optimal results, ensuring your components stand out in both performance and style.

Trust us to bring a new level of excellence to your metal products with our comprehensive chrome solutions.

Zemetal: Who We Are

Our Founding Journey

Established with a vision to revolutionize the sheet metal processing industry, our journey reflects a blend of innovation, precision, and dedication. From our humble beginnings, we’ve evolved into a leader in sheet metal processing and batch production. Our success is built on a commitment to quality and relentless technological advancement, setting new standards in the industry.

Inside Our Facility

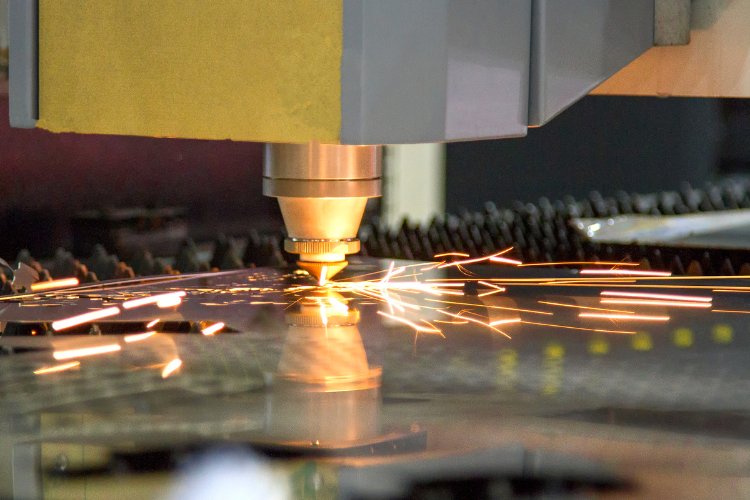

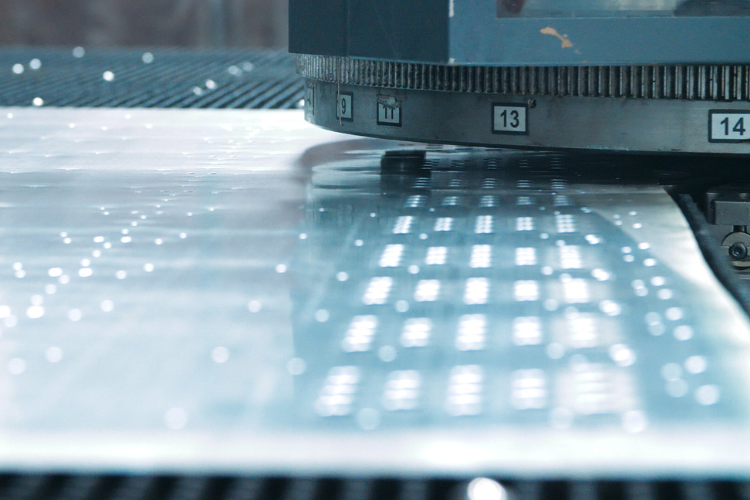

Step into our state-of-the-art factory, where advanced technology meets skilled craftsmanship. Optimally designed for efficiency, our facility is the heart of our sheet metal production. We handle intricate designs and large-scale outputs with precision, ensuring every product meets the highest quality benchmarks. Our factory is a testament to our capability to handle diverse, high-volume demands with precision.

Innovation & Development

At the core of our operation is a robust Research & Development wing, pushing the frontiers of sheet metal processing. Our R&D team, equipped with cutting-edge tools and driven by innovation, continually develops new methods to enhance efficiency and product quality. This relentless pursuit of improvement sets us apart and ensures we stay ahead in a rapidly evolving industry.

Certification Excellence

Our commitment to excellence is affirmed by our comprehensive range of industry certifications. Each certificate represents our adherence to stringent quality standards, environmental practices, and safety protocols. These certifications are a promise to our clients that every sheet metal product we deliver is crafted to perfection, adhering to the highest industry benchmarks. Trust and quality are the pillars of our service.

Meet the Experts Behind Zemetal

01

Media Team

For content collaborations or to join our blog contributors, please contact [email protected]. We welcome fresh perspectives and are committed to enriching our metal sheet fabrication industry platform with diverse insights. Let’s innovate together.

02

Quality Assurance Team

In our Quality Assurance Team, we meticulously ensure a 99.8% precision rate in every project, embodying our dedication to superior quality and a zero-error approach in metal sheet fabrication.

03

Research & Development Team

Leading with over 30 innovative techniques, our R&D Team enhances fabrication efficiency and precision by 25%, constantly redefining creativity and scientific accuracy in metal sheet fabrication.

04

Engineering & Design Team

Our Engineering & Design Team, with over 500 bespoke projects, expertly fuses creative design with engineering precision, ensuring each fabrication project excels in functionality and aesthetics.

Empowering Goals With Us

At Zemetal, our partnership with a pioneering electric vehicle firm is a testament to our dedication to precision, sustainability, and efficiency. Utilizing our cutting-edge fabrication skills and eco-friendly practices, we played a pivotal role in addressing critical challenges faced by Mr. Frazier's company. This collaboration resulted in a staggering 30% enhancement in vehicle performance, marking a significant milestone in our journey towards innovative excellence.

Our collaboration with Mr. Virden's HVAC company is a shining example of Zemetal's commitment to delivering bespoke metal fabrication solutions that are both innovative and efficient. By embracing and solving unique architectural challenges, we not only improved the functionality of their HVAC systems but also seamlessly integrated them into the desired aesthetics. This strategic partnership led to substantial growth for our client, showcasing the transformative impact of our tailored solutions.

Working with Mr. Park and his team at the automotive company highlighted Zemetal's unwavering commitment to precision, innovation, and efficiency. By confronting their complex challenges with our advanced manufacturing techniques, we didn't just meet their high standards; we played a crucial role in significantly boosting their vehicle performance. This collaboration underscores our dedication to pushing the boundaries of what's possible in automotive excellence.

Previous

Next

Your Manufacturing Demands, Our Expert Solutions

Comprehensive Fabrication Services

Offering a wide range of metal fabrication services, from cutting and bending to welding and assembling, tailored

to your specific requirements.

Advanced Technology & Equipment

Utilizing state-of-the-art machinery and technology to ensure high precision and quality in every project, meeting the

most demanding manufacturing standards.

Expert Team & Quality Assurance

Our skilled professionals are committed to delivering excellence. We adhere to strict quality control protocols to

ensure top-notch results.

Flexible Production Capacity

Whether you need a single prototype or large-scale production, our flexible manufacturing processes can adapt to your project’s scale and complexity.

Timely Delivery & Customer Support

We understand the importance of deadlines. Our efficient processes and dedicated support team ensure timely delivery and ongoing communication throughout your project.

Sustainable Practices & Material Options

Committed to environmental responsibility, we offer sustainable manufacturing practices and a variety of material choices, including eco-friendly and recycled options, to meet both

your project needs and environmental goals.

Types of Chrome Plating Services

Black Chroming

Black chroming is a specialized form of chrome plating, offering a sleek, dark finish that adds a unique aesthetic to metal components. Commonly used in automotive and decorative applications, this process involves a complex layering of chromium to achieve its distinct black color. It’s favored for its corrosion resistance and visually striking appearance.

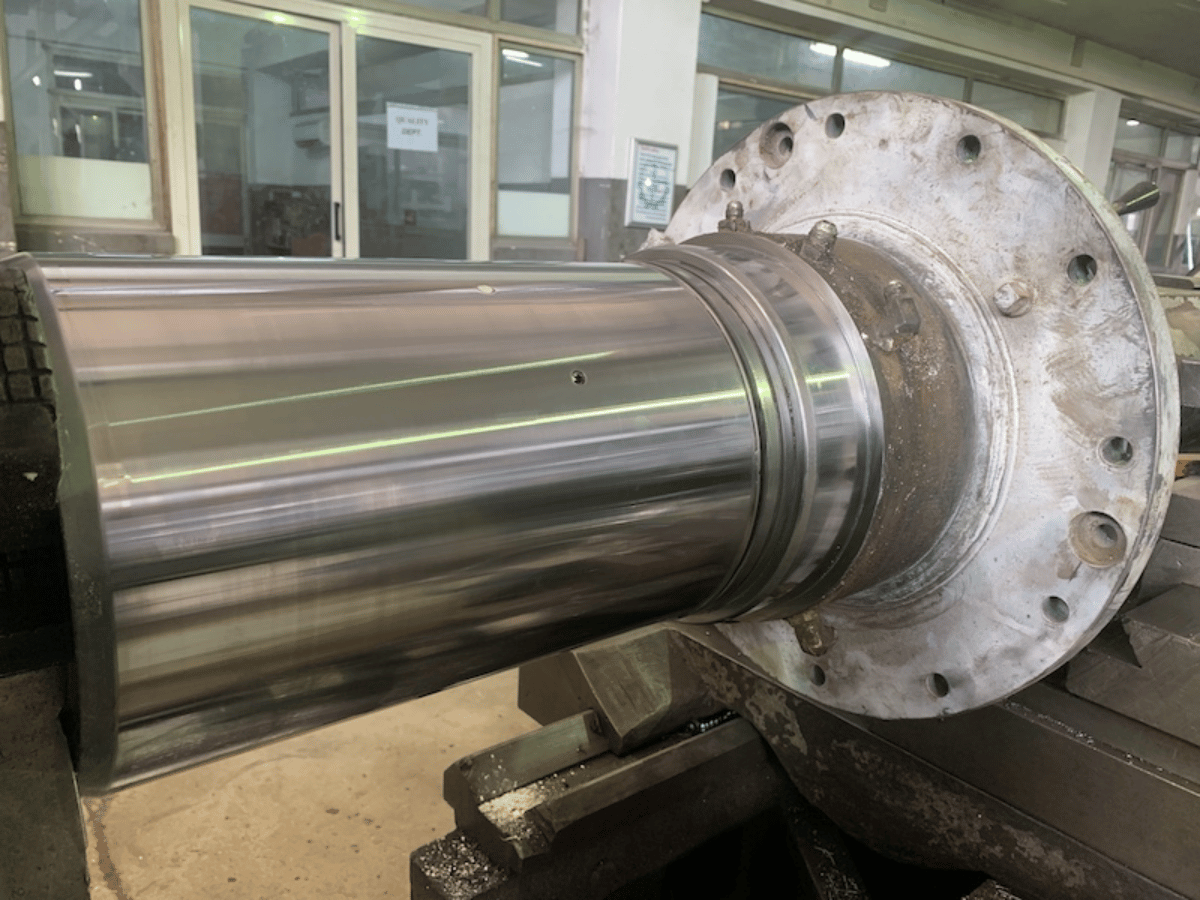

Hard Chromed

Hard chromed surfaces are known for their exceptional durability and wear resistance. This technique is particularly beneficial in industrial applications where components are exposed to high friction and need to withstand heavy use. It involves electrodepositing a thick layer of chromium onto metal surfaces, creating a hard, protective coating. This process is instrumental in extending the lifespan of machinery and tools.

Powder Coating Chrome

Powder coating chrome is an innovative method that combines the durability of traditional chrome plating with the versatility of powder coating. This process is environmentally friendly, emitting fewer volatile organic compounds compared to conventional liquid coatings. It provides a robust, uniform finish that resists chipping, fading, and scratching, making it ideal for both industrial and consumer applications.

Electroplating Chrome

Chrome electroplating is a widely used technique in chrome plating services. An example of its application can be seen in automotive parts, where it provides both aesthetic appeal and resistance to corrosion. This process involves using an electrical current to deposit a thin layer of chromium onto a metal object, creating a shiny and protective surface.

Chrome Plating on Aluminum

Chrome plating on aluminum offers the lightweight properties of aluminum with the durability and shine of chrome. This combination is perfect for components requiring both strength and aesthetic appeal. At Zemetal, I have seen that the process includes a pre-treatment of the aluminum surface before applying the chrome layer, ensuring strong adhesion and a flawless finish.

Pvd Chrome Plating

PVD (Physical Vapor Deposition) chrome plating is a cutting-edge technique that offers superior durability and a distinct finish. This method is known for its ability to create a more uniform coating than traditional plating methods. PVD chrome plating is often used in high-end automotive and aerospace industries for its exceptional quality and longevity.

Zinc Yellow Chromate Plated

Zinc yellow chromate plating provides excellent corrosion resistance, making it a popular choice for outdoor and marine applications. The yellow chromate coating acts as a sacrificial layer, protecting the base metal from oxidizing. This process is essential in ensuring the longevity of metal components exposed to harsh environmental conditions.

Brass Chroming

Chroming brass involves applying a chrome finish to brass components, enhancing their corrosion resistance and aesthetic appeal. The result is a brilliant, reflective surface that adds a touch of elegance to any application. This process is particularly popular in decorative fixtures and musical instruments, where both appearance and durability are paramount.

Flash Chrome Plating

Flash chrome plating is a thin chrome coating applied to metal surfaces for added corrosion resistance and aesthetic enhancement. It is an ideal solution for parts that require a light chrome finish without additional weight or thickness. This process is commonly used in electronic components and precision engineering applications.

Sandblasting Chrome Plating

Sandblasting chrome plating involves pre-treating the metal surface with sandblasting before applying the chrome layer. This process ensures a clean, roughened surface for better adhesion of the chrome. It is particularly effective for restoring old or corroded parts, giving them a new lease on life with a fresh chrome finish.

Anodized Chrome

Anodized chrome provides a hard, durable surface that is resistant to wear and corrosion. This process involves an electrochemical procedure that enhances the natural oxide layer on metal surfaces. Anodized chrome is often used in architectural and automotive applications for its longevity and sleek appearance.

Thin Dense Chrome

Thin dense chrome offers a fine, dense coating, ideal for precision components requiring a thin yet durable layer of protection. This method is favored in the aerospace and defense industries for its ability to maintain tight tolerances. The thin dense chrome layer provides exceptional wear resistance without altering the dimensions of the component.

Triple Chrome Plating

Triple chrome plating is a process that involves applying three layers of plating: copper, nickel, and chrome. This combination provides superior corrosion resistance and a mirror-like finish. It is commonly used in automotive, motorcycle, and decorative applications for its impressive appearance and long-lasting protection.

Black Chroming

Hard Chromed

Powder Coating Chrome

Electroplating Chrome

Chrome Plating on Aluminum

Pvd Chrome Plating

Zinc Yellow Chromate Plated

Brass Chroming

Flash Chrome Plating

Sandblasting Chrome Plating

Anodized Chrome

Thin Dense Chrome

Applicable Materials for Chrome Plating Services

Zinc and Zinc Alloys

Zinc and zinc alloys are excellent candidates for chrome plating, particularly in applications requiring good corrosion resistance at a lower cost than other metals. Chrome plating on zinc and its alloys provides an additional layer of protection against environmental factors, enhancing the material’s longevity. This process is often employed in the manufacturing of small components in various industries.

Copper and Brass

Copper and brass are frequently used in chrome plating for their excellent conductivity and heat resistance. An example of their use can be seen in plumbing fixtures, where the aesthetic appeal of chrome adds value to the inherently functional characteristics of these metals. Zemetal’s chrome plating on copper and brass not only enhances their appearance but also significantly improves their resistance to tarnishing and corrosion.

Steel and Iron

Steel and iron are the most common materials used in chrome plating services due to their strength and durability. The chrome plating process enhances these materials’ natural resistance to corrosion and wear, making them ideal for a wide range of applications, from automotive parts to household fixtures. When chrome plated, these metals not only become more durable but also gain an aesthetically pleasing exterior.

Aluminum

Aluminum is a popular choice for chrome plating, especially in applications where weight is a concern. Despite its lightweight nature, aluminum can achieve a high level of durability and corrosion resistance when chrome plated. This makes it a preferred material in the aerospace and automotive industries. The chrome plating process for aluminum usually includes a pre-treatment to ensure proper adhesion and a flawless finish.

Zinc and Zinc Alloys

Copper and Brass

Steel and Iron

Aluminum

Features and Benefits of Chrome Plating Services

Features of Chrome Plating Services

Post-Plating Quality Assurance

Post-plating quality assurance is an important feature, where the finished product undergoes thorough testing and inspection. This ensures that the chrome plating meets all quality standards and specifications, guaranteeing a high level of satisfaction and performance.

Advanced Plating Techniques

Another feature of chrome plating services is the use of advanced plating techniques. Companies like Zemetal utilize state-of-the-art technology and methods to ensure a high-quality finish. This includes precise control over plating thickness, adherence to industry standards, and the ability to handle a variety of materials and shapes.

Benefits of Chrome Plating Services

Corrosion and Wear Resistance

Chrome plating services offer the benefit of increased corrosion and wear resistance. From my previous experience, this makes the treated items more durable and suitable for harsh environments. This reduces the need for frequent replacements or repairs.

Value Addition to Products

When businesses opt for chrome plating services, they invest in a transformative process that significantly enhances the value of their products. The sleek, mirror-like finish achieved through chrome plating not only elevates the aesthetic appeal of items but also conveys a sense of higher quality and sophistication.

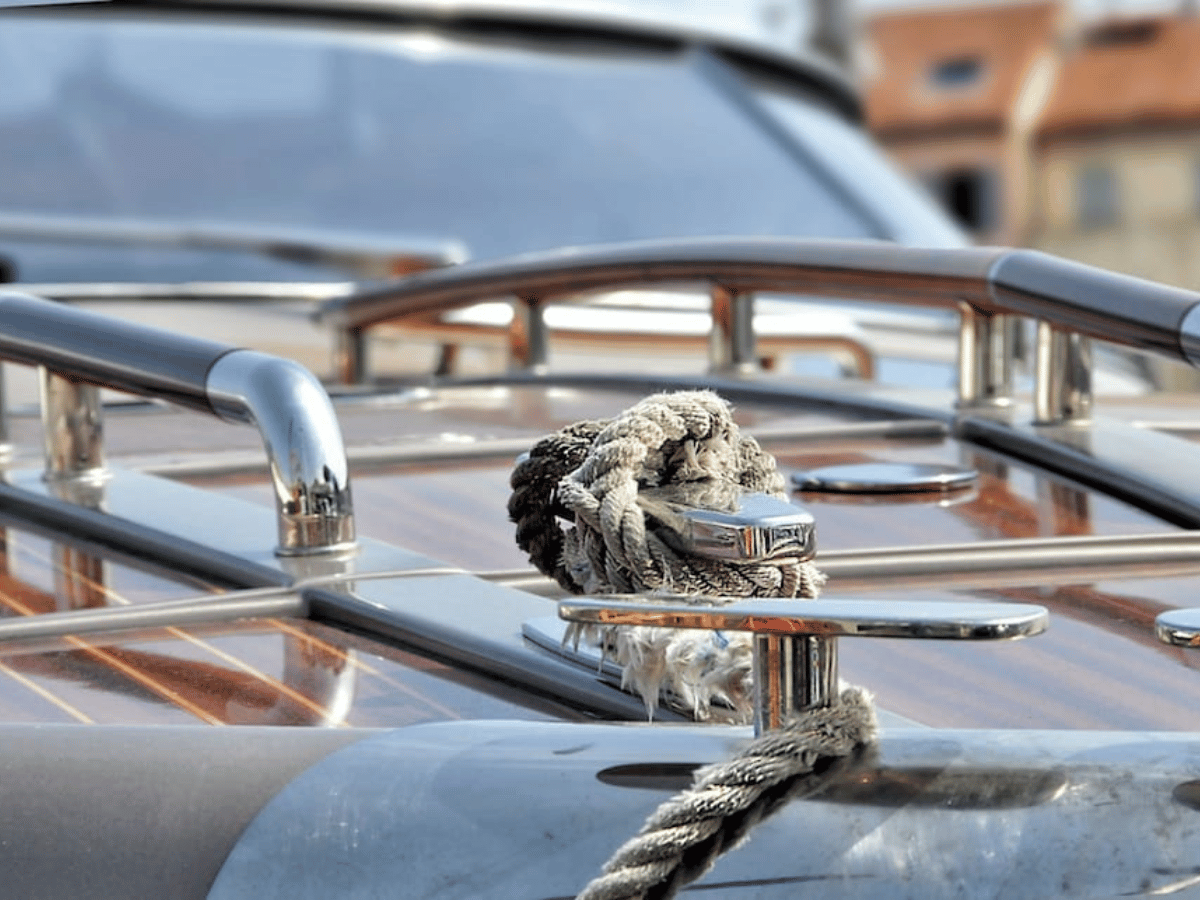

Applications of Chrome Plating Services

Marine Industry

The marine industry benefits greatly from chrome plating services due to the enhanced corrosion resistance they provide. This is crucial in a marine environment, where components are constantly exposed to saltwater and harsh conditions. Chrome plating advantages in the marine industry ensure that marine parts remain durable and functional, while also maintaining their aesthetic quality.

Consumer Electronics

Chrome plating services are increasingly popular in the consumer electronics industry, where they are used to enhance the durability and appearance of various devices. For instance, chrome plating is often seen on electronic connectors and switches, providing both functional and aesthetic benefits. I have seen this treatment ensures longevity and maintains the sleek look of electronic products.

Oil and Gas Industry

In the oil and gas industry, chrome plating services are essential for protecting equipment and machinery from the harsh conditions and corrosive substances encountered in this sector. Zemetal’s chrome plating solutions are particularly valued in this industry for their ability to significantly extend the life and maintain the integrity of components used in exploration, drilling, and processing activities.

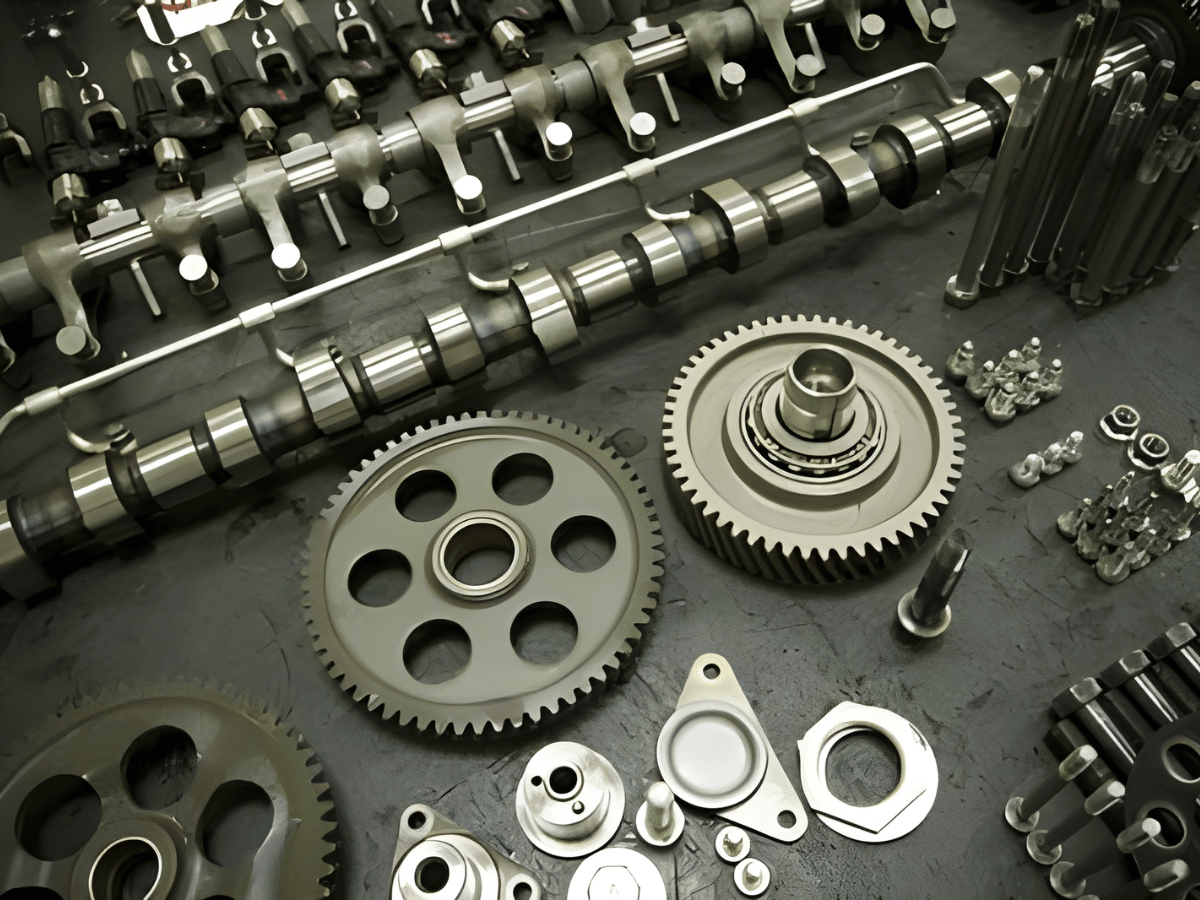

Automotive Industry

The automotive industry heavily relies on chrome plating services for both functional and aesthetic purposes. Chrome plating is used on a variety of automotive parts such as bumpers, rims, and engine components, enhancing their durability and visual appeal. This treatment is essential for protecting parts against corrosion and wear, while also giving vehicles a sleek, high-end look.

Marine Industry

Oil and Gas Industry

Automotive Industry

3 Things to Consider When Choosing Chrome Plating Services

#1 Quality of Plating

When choosing chrome plating services, the quality of the plating itself is paramount. A high-quality chrome finish is not only about aesthetic appeal but also about ensuring durability and resistance to wear and corrosion. It’s essential to select a service provider who adheres to industry standards and uses advanced techniques to achieve a consistent, high-quality finish.

#2 After-Sales Support

The level of after-sales support offered by the service provider should be taken into account. Zemetal’s commitment to client satisfaction, including comprehensive after-sales services, ensures that any issues or concerns post-completion are promptly and effectively addressed. This aspect is crucial for maintaining the quality and longevity of the chrome-plated products.

#3 Finished Product Customization

Finished product customization is an essential factor to consider when choosing chrome plating services. It’s important to select a service provider that understands your specific needs and can tailor their process to achieve the desired results. Whether it’s achieving a particular aesthetic, adhering to precise dimensions, or ensuring compatibility with other components, the ability to customize the finished product is crucial.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Meet Our Best Sheet Metal Fabrication Laser Cutting Blanking Stamping Weilding Bending Services

Connect with Us

Zemetal is committed to ensuring your privacy and promises prompt, secure responses to all your inquiries.