Ever wondered what sets apart high-performance metal products in today’s market? Chrome plating stands as a key factor, enhancing durability and aesthetic quality.

As an expert in the field, I bring a wealth of experience and technical know-how. My insights are grounded in industry-leading practices and innovations in chrome plating.

Chrome plating is not just a process; it’s an art that balances chemical complexities with practical application, ensuring longevity and visual appeal of metal products.

In this ultimate guide, we’ll explore the ideas of various chrome plating techniques, their benefits, and how they can be optimally utilized in your business operations.

Read on to unlock the secrets of mastering chrome plating techniques.

1. Defining Chrome Plating

Building on the importance of chrome plating in the market, it’s essential to understand what exactly it entails. Chrome plating is a technique where a thin layer of chromium is electroplated onto a metal object. This process involves submerging the object into a chromic acid solution and applying an electric current, which leads to the chromium layer adhering to the surface.

The result is not just a visually striking finish. Chrome plating significantly enhances the metal’s resistance to corrosion and wear, making it a preferred choice for various industrial applications. Its versatility and efficiency in improving product durability make it an invaluable process in metal manufacturing.

2. Benefits of Chrome Plating

Understanding the fundamental process of chrome plating sets the stage to appreciate its numerous benefits. These advantages are crucial for businesses. Here’s a breakdown:

- Enhanced Durability: Chrome plating adds a robust layer to metal products, significantly increasing their lifespan. This layer acts as a shield against corrosion, wear, and tear, ensuring the longevity of metal components in various environments.

- Improved Aesthetics: The chrome layer imparts a sleek, shiny finish that is visually appealing. This aesthetic enhancement is ideal for consumer-facing products, where appearance can be as important as functionality.

- Corrosion Resistance: One of the primary benefits of chrome plating is its exceptional corrosion resistance. This makes it suitable for use in harsh environments, protecting the base metal from rust and degradation.

- Ease of Cleaning: Chrome-plated surfaces are easy to clean and maintain. Their smooth and non-porous nature means they can be wiped clean of dust, dirt, and grime, maintaining their shine over time.

- Versatility: Chrome plating is versatile and can be applied to a wide range of metals, including steel, copper, and brass. This flexibility makes it a preferred choice for diverse industrial applications.

3. Types of Chrome Plating

After delving into the benefits of chrome plating, it’s crucial to understand its different types to select the best fit for specific applications. Here are some of the common types:

Decorative Chrome Plating

Decorative chrome plating, often used for its aesthetic appeal, involves a thinner layer of chromium. This type typically follows a layer of nickel, which adds smoothness and further corrosion resistance. Decorative chrome is known for its mirror-like finish, making it a popular choice for automotive parts, household fixtures, and hardware. One example is the shiny exterior of kitchen faucets often feature decorative chrome plating.

Hard Chrome Plating

Hard chrome plating, also known as industrial chrome or engineered chrome, is used to reduce friction, improve durability, and extend the life of equipment. This type involves a much thicker layer of chromium applied to heavy-duty industrial parts. Zemetal specializes in providing hard chrome plating services, ensuring that industrial components are not only durable but also maintain their efficiency over extended periods.

4. Materials and Equipment Used in Chrome Plating

Transitioning from the types of chrome plating, it’s insightful to explore the materials and equipment that make this process possible. See the following key components involved:

Chromic Acid

Chromic acid is the core chemical used in the chrome plating process. It serves as the primary source of chromium in the electroplating bath. The quality and concentration of chromic acid significantly impact the finish and quality of the plating. I believe, ensuring the right concentration of chromic acid is critical for achieving the desired thickness and sheen of the chrome layer.

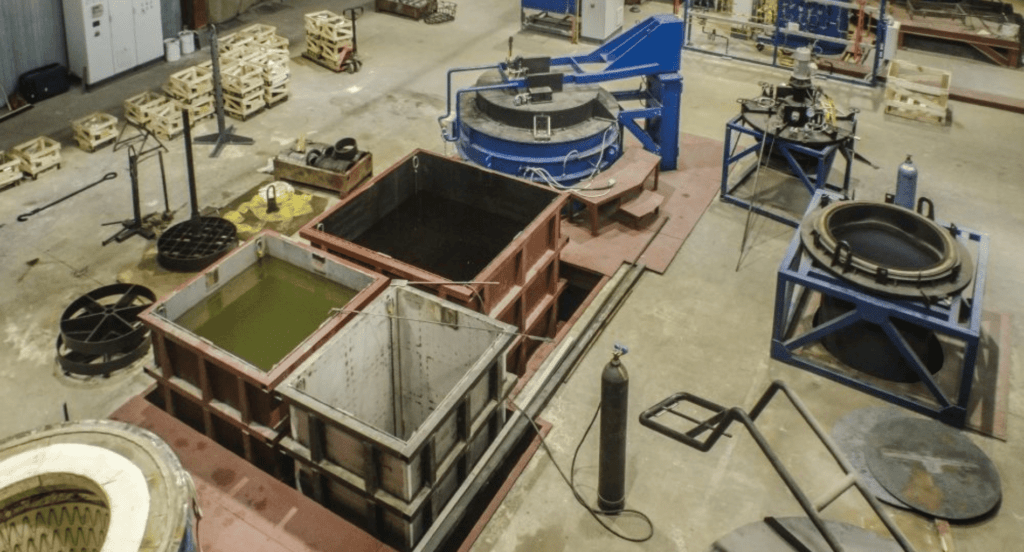

Electroplating Tank

The electroplating tank is where the actual chrome plating process occurs. These tanks are designed to hold the chromic acid solution and the metal object being plated. They are typically made of materials resistant to the corrosive nature of chromic acid, ensuring safety and durability. For instance, tanks used in decorative plating are often smaller compared to those used for hard chrome plating.

Power Supply

A controlled and stable power supply is crucial for chrome plating. It provides the electrical current necessary for the electroplating process, facilitating the transfer of chromium ions onto the metal surface. The power supply must be adjustable, as different plating requirements demand varying levels of current and voltage. In hard chrome plating, for example, a higher current is often required to achieve a thicker chrome layer.

Anodes and Cathodes

Anodes and cathodes are essential for the electrochemical process in chrome plating. The metal object to be plated is typically connected to the cathode, while the anode is usually made of lead, facilitating the flow of electrons. The placement and quality of these components are key to achieving an even distribution of chromium on the metal surface.

5. The Chrome Plating Process

Having looked at the essential materials and equipment, it’s time to delve into the chrome plating process itself. Below are the key steps involved:

Step#1 Surface Preparation

The initial and crucial step in chrome plating is surface preparation. The metal object must be thoroughly cleaned to remove any dirt, grease, or existing coatings. This can involve a series of cleaning methods, such as degreasing, pickling, and sandblasting. The quality of the final product is heavily dependent on how well the surface is prepared. Any residue left on the surface can lead to poor adhesion and defects in the plating.

Step#2 Electroplating Bath Setup

Once the surface is prepared, the object is submerged in an electroplating bath containing chromic acid. The concentration and composition of the solution are carefully controlled. This step is important for determining the thickness and characteristics of the chrome layer. It is important to ensure that electroplating baths are carefully maintained to achieve consistent and high-quality results.

Step#3 Application of Electrical Current

The next step involves applying an electrical current through the solution. This causes chromium ions in the solution to deposit onto the metal’s surface. The amount of current and duration of the process vary depending on the desired thickness and type of chrome plating. For decorative plating, lower current and shorter duration is often sufficient, while hard chrome plating requires higher current and longer plating time.

Step#4 Rinsing and Drying

After the electroplating process, the plated object is removed from the bath and thoroughly rinsed with water. This step is crucial to remove any residual chemicals and to stop the plating process. The object is then dried, often using air blowers or in drying ovens. Emphasize the importance of thorough rinsing and drying to prevent any post-plating issues like spotting or staining.

Step#5 Quality Inspection

The final step is the quality inspection. This includes checking the thickness, adhesion, and overall quality of the chrome plating. In some cases, additional tests for corrosion resistance and hardness may be conducted. The goal is to ensure that the chrome-plated product meets the required specifications and standards. Zemetal takes pride in its strict quality control processes, ensuring every product meets the highest standards.

6. Applications of Chrome Plating

Following the exploration of the chrome plating process, it’s insightful to look at its various applications. Here are some of the key areas where chrome plating is extensively used:

Automotive Industry

Chrome plating is heavily utilized in the automotive industry, particularly for enhancing the appearance and durability of vehicle parts. Components such as bumpers, rims, door handles, and grills are often chrome-plated for added aesthetic appeal and resistance to wear and tear. Beyond aesthetics, chrome plating in automotive parts also provides a layer of protection against environmental factors like moisture and salt.

Consumer Goods

In the realm of consumer goods, chrome plating is applied to a wide range of products, from kitchen appliances and bathroom fixtures to jewelry and watches. The shiny, reflective finish of chrome plating adds a touch of elegance and luxury to these products. Additionally, the protective layer extends the life of these items, making them more durable and resistant to tarnishing.

Industrial Equipment

Chrome plating is not limited to aesthetic applications; it plays a significant role in enhancing the functionality and lifespan of industrial equipment. Components like hydraulic piston rods, cylinders, and various machinery parts are often chrome-plated for added strength and resistance to corrosion and wear. Industries value chrome plating for its ability to reduce friction, prevent galling, and maintain the integrity of equipment.

7. Maintenance and Care Tips for Chrome-Plated Items

Understanding the applications of chrome plating leads naturally to the question of maintenance. Proper care is essential to preserve the integrity and appearance of chrome-plated items. See the following tips:

Regular Cleaning

The first step in maintaining chrome-plated items is regular cleaning. It’s important to clean them gently using a soft cloth or sponge and a mild soap or detergent. Harsh chemicals or abrasive cleaners can damage the chrome finish. After cleaning, rinse the items thoroughly with water and dry them with a soft cloth to prevent water spots. This simple routine helps maintain the luster and prevent the buildup of dirt or grime.

Regular Inspections

Regular inspections play a role in maintaining chrome-plated items. This involves checking for any signs of wear, corrosion, or damage. Early detection of such issues can allow for timely intervention, potentially saving costs on extensive repairs or replacements. Especially with industrial chrome-plated components, routine inspections have often been the difference between a minor touch-up and a major re-plating job.

This table outlines the vital aspects of regular inspections for chrome-plated items, highlighting their role in early detection and prevention of major issues.

| Inspection Focus | Description | Importance in Maintenance |

| Wear Signs | Checking for surface deterioration | Prevents progression to significant damage |

| Corrosion Detection | Identifying rust or corrosion early | Essential for structural integrity |

| Damage Evaluation | Assessing for cracks, chips, or deformities | Aids in timely repair and touch-ups |

| Structural Integrity | Ensuring the chrome plating is still effective | Key to maintaining item functionality |

| Regularity of Inspections | Consistent scheduling for preventative care | Minimizes need for extensive repairs |

Proper Handling and Storage

Proper handling and storage are key to preventing scratches and dents on chrome-plated items. Avoid stacking or storing heavy items on top of chrome-plated surfaces. If the items are not in use, storing them in a dry, clean environment can prevent tarnishing and corrosion. In industrial settings where chrome-plated machinery parts are common, ensuring they are stored away from corrosive materials is crucial.

8. 3 Factors to Consider When Opting for Chrome Plating

After the maintenance and care of chrome-plated items, it’s equally important to consider the initial choice of chrome plating. As per Volza, chrome plating import shipments in the world stood at 321.8K. Here’s a list of key factors to keep in mind:

#1 Technical Support and Consultation

Technical support and consultation capabilities are critical and essential. A service provider with strong technical expertise can offer valuable advice on the best plating methods and materials for specific applications. They can also assist in troubleshooting any issues during the plating process or in the application of the plated item. Comprehensive consultation services demonstrate a depth of knowledge and commitment.

#2 Industry-Specific Experience

Consider the service provider’s experience in your specific industry. Different industries may have unique chrome plating requirements, standards, or certifications. A provider with experience in your industry will likely be more attuned to these specific needs and regulatory requirements, ensuring a smoother and more efficient service experience.

#3 Geographic Location and Logistics

Proximity can play a significant role in reducing transportation costs and facilitating easier communication and collaboration. Additionally, local providers might better understand specific regional requirements or regulations. However, in certain cases, a more distant provider might offer specialized services not available locally. Balancing location and logistical convenience with service quality is key.

Conclusion

Knowing the chrome plating techniques offers valuable insights for businesses looking to enhance their products’ durability and aesthetic appeal. This comprehensive guide serves as a resourceful tool for making informed decisions in the world of metal finishing.

For those seeking expert chrome plating services, Zemetal offers custom solutions that meet a wide range of industrial needs. Discover how our expertise can benefit your business. Contact us today!

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

History and Innovations

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.