Wondering who offers the most reliable sheet metal forming services in China? Choosing the right manufacturer can greatly impact your business.

As an Industrial Designer with experience in China’s sheet metal forming industry, I’ve worked with several manufacturers and know their strengths and quality.

After reviewing 7 top companies, I found Zemetal to be the best for their advanced technology and consistent production.

In this review, I’ll show you what makes these manufacturers stand out and how they can meet your fabrication needs.

So let’s begin!

1. Zemetal – Best in Overall

City & Country: China

Established Date:

Zemetal, a leader in precision metal parts fabrication and assembly, is acclaimed for its exceptional workmanship and flexibility. Their dedication to quality and reliability cement their position as a top-tier metal fabrication service provider. With a history of over 20,000 successful projects, Zemetal has gained the trust of more than 3,500 buyers globally, showcasing their prowess in the industry.

Key Services: Their main services include Sheet Metal Bending and Sheet Metal Welding. Sheet Metal Bending shapes metal sheets into desired angles and forms, ensuring precision in production. Sheet Metal Welding joins these bent components securely, creating durable and robust metal structures.

Takeaway Note:

Zemetal excels in providing high-quality sheet metal bending and welding services, standing as a testament to their commitment to excellence. Their services are not just transactions but partnerships, ensuring that each project meets the highest standards of precision and quality.

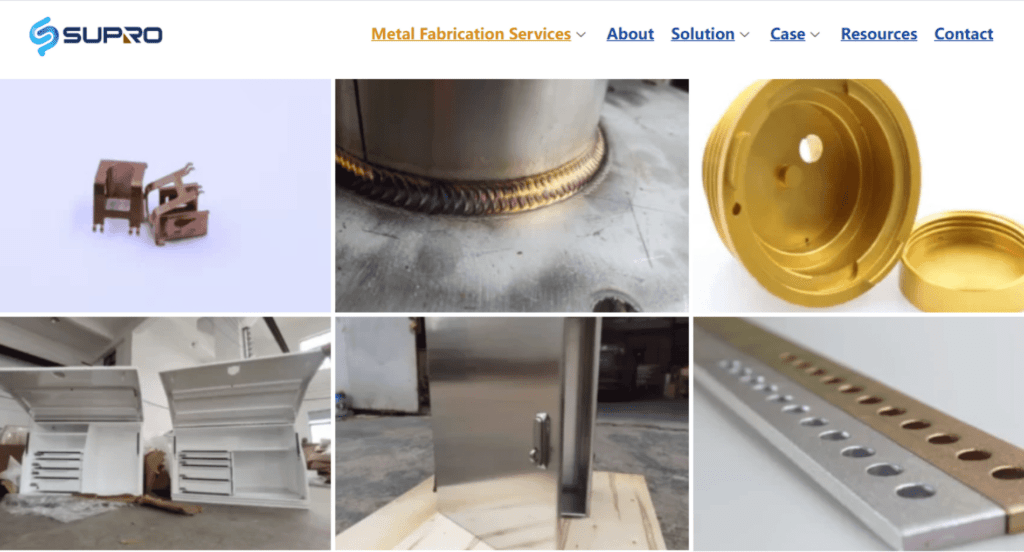

2. China Supro Manufacturing – Best in On-Demand Customized Manufacturing

City & Country: Shanghai, China

Established: 2006

China Supro Manufacturing leads the way in sheet metal fabrication, with a strong focus on product design and manufacturing services. Adhering to ISO9001-2015 quality standards, they excel in delivering innovative on-demand manufacturing of customized products. Their digital intelligent manufacturing production lines stand as a testament to their commitment to technological advancement and quality.

Key Services: Their main services include Metal Fabrication and Aluminum Extrusion Services. Metal Fabrication involves cutting, bending, and assembling metal materials into custom designs. Aluminum Extrusion Services shape aluminum into specific profiles by forcing it through a die, creating lightweight yet strong components.

Takeaway Note:

China Supro Manufacturing’s expertise in on-demand customized production ensures clients receive products that precisely meet their requirements. However, this focus on customized solutions may not align with clients looking for more standardized, off-the-shelf products.

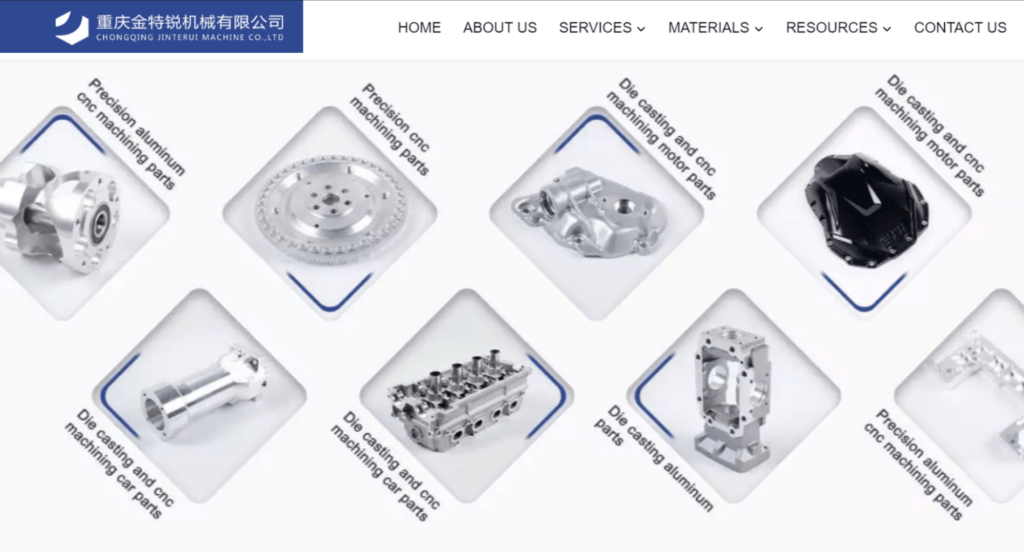

3. Chongqing Jin Te Rui Machine – Best in Integrated Manufacturing Solutions

City & Country: Chongqing, China

Established: 2012

Chongqing Jin Te Rui Machine stands out for its ability to seamlessly integrate product design with development, offering high-quality manufacturing solutions that efficiently bring designs to life. Their rich manufacturing experience and professional technical support have resulted in the successful delivery of over 20,000 projects, earning the trust of more than 3,500 buyers globally.

Key Services: Their main services include Sheet Metal Fabrication and Rapid Prototyping. Sheet Metal Fabrication transforms metal sheets into custom parts and structures. Rapid Prototyping quickly produces prototypes of these designs, allowing for efficient testing and refinement before mass production.

Takeaway Note:

Chongqing Jin Te Rui Machine excels in sheet metal fabrication and rapid prototyping. However, their specialization in rapid prototyping and manufacturing may not cater to clients requiring more traditional, long-term production strategies.

4. Jingxin Precision Machinery – Best in Custom Manufacturing Solutions

City & Country: Guangdong Province, China

Established: 2003

Jingxin Precision Machinery’s approach is deeply rooted in a comprehensive understanding of the nuances of custom manufacturing, yielding products that offer rapid returns on investment and reliability that is second to none. Their rich manufacturing experience and professional technical support have led to the successful delivery of more than 20,000 projects, solidifying their reputation among over 3,500 buyers worldwide.

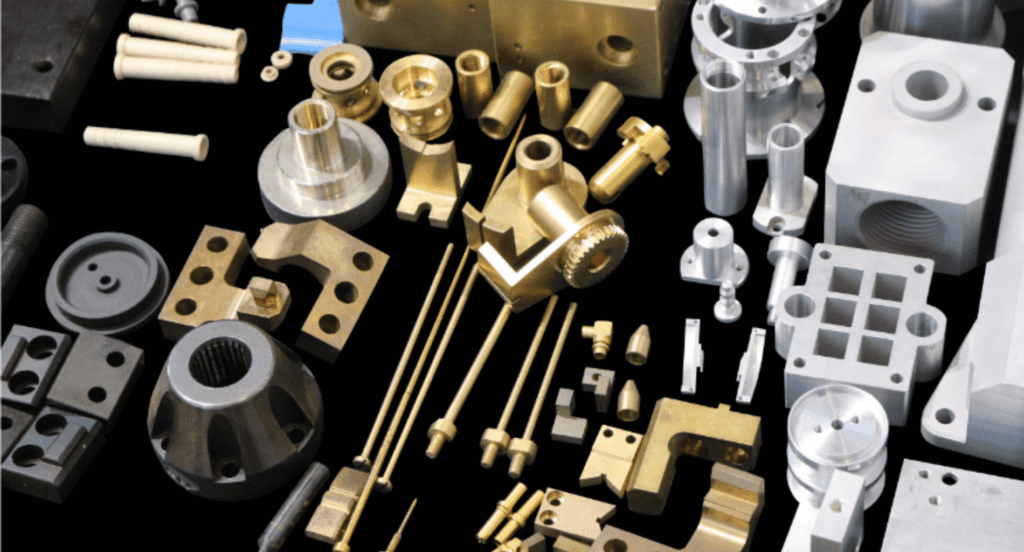

Key Services: Their main services include Metal Stamping and Vacuum Casting. Metal Stamping uses dies to cut and form metal sheets into precise shapes. Vacuum Casting creates detailed parts by pouring liquid material into a mold under vacuum, ensuring high-quality reproduction of intricate designs.

Takeaway Note:

Jingxin Precision Machinery’s services reflect a perfect blend of quality and efficiency. However, their specialized focus on custom manufacturing might not suit clients looking for more standardized or mass-produced items.

5. IN3DTEC – Best in Advanced Production Solutions

City & Country: Shanghai, China

Established: 2014

IN3DTEC leads the field in advanced prototyping and production solutions. The company offers a comprehensive array of technologies, including 3D scanning, industrial 3D printing, reverse engineering, vacuum casting, injection molding, and die casting. This diverse range of services establishes them as a one-stop station for both prototyping and on-demand production needs.

Key Services: Their main services include Vacuum Casting and Metal Printing Services. Vacuum Casting produces highly detailed and accurate parts by using molds under vacuum pressure. Metal Printing Services, often using 3D printing technology, create complex metal components layer by layer for innovative designs and solutions.

Takeaway Note:

IN3DTEC’s wide range of services makes them an invaluable asset for businesses seeking comprehensive prototyping and production solutions. However, the breadth of their services might not cater to clients who require more focused or traditional manufacturing approaches.

6. Junying Metal Manufacturing – Best in Precision Engineering

City & Country: Guangdong, China

Established: 2005

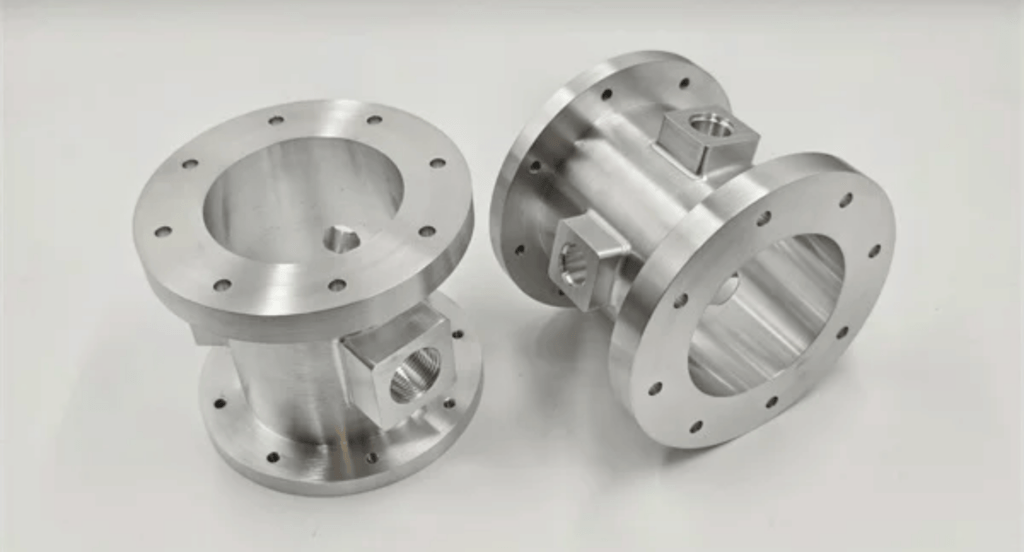

Junying Metal Manufacturing’s unwavering commitment to quality is evident in their ISO9001:2015 certification, ensuring clients receive machining parts that strike a balance between top-quality and affordability. Their dedication to maintaining high standards in machining techniques positions them as a reliable name in the field of precision engineering.

Key Services: Their main services include Sheet Metal Fabrication and Precision Machining. Sheet Metal Fabrication forms metal sheets into specific shapes and structures. Precision Machining ensures high accuracy and exact dimensions, providing finely detailed metal components for various industries.

Takeaway Note:

Junying Metal Manufacturing offers services that embody their commitment to quality and precision. However, their emphasis on specialized precision machining and mold craftsmanship might not cater to clients requiring more general fabrication services.

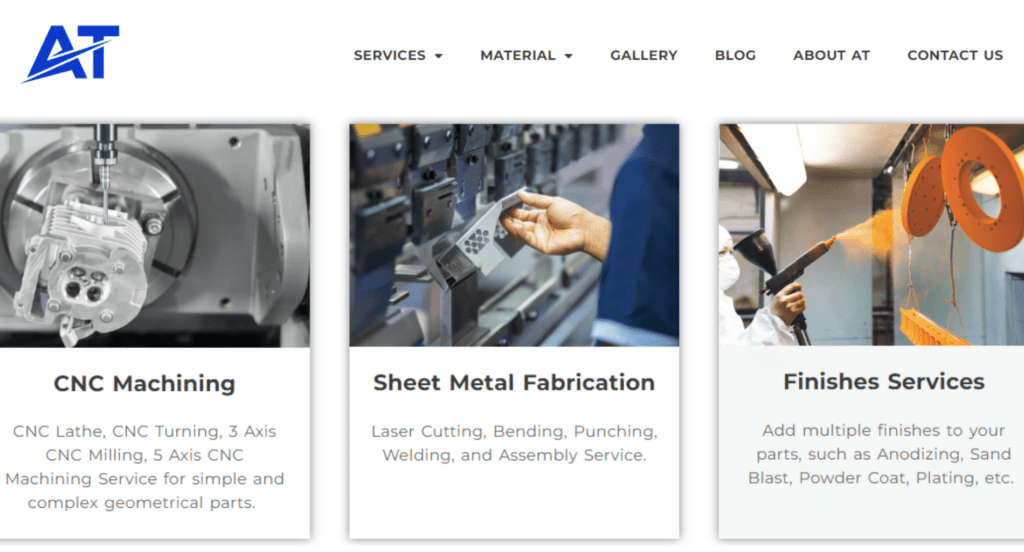

7. AT – Best in Precision Machining Expertise

City & Country: Shenzhen, China

Established: 2007

AT specializes in professional precision machining. They excel in rapid prototyping and offer short to medium run production machining services, attracting a global customer base. Positioning themselves as a one-stop machine shop, they enable businesses to focus on their core operations while handling complex machining needs.

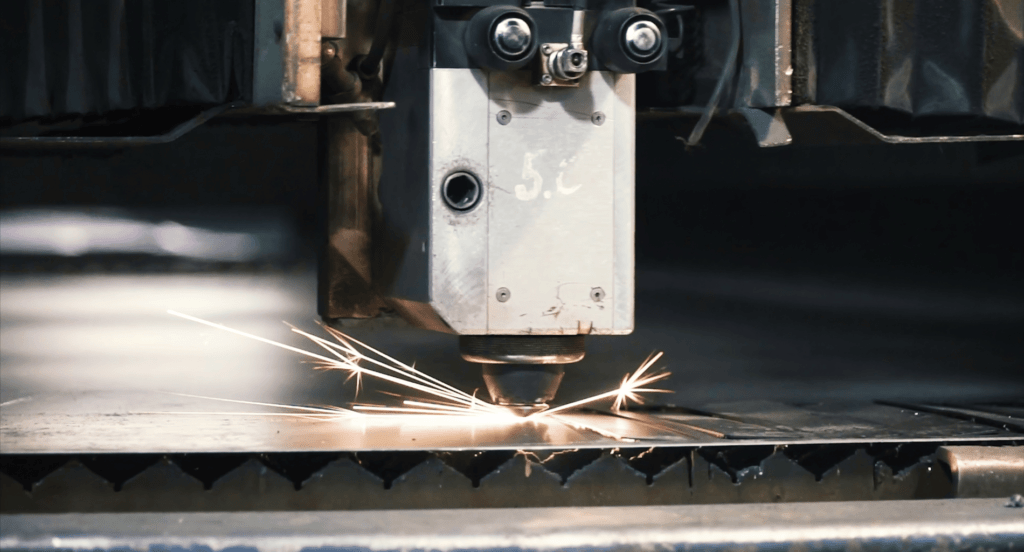

Key Services: Their main services include Sheet Metal Fabrication and Laser Cutting Services. Sheet Metal Fabrication shapes and assembles metal sheets into custom products. Laser Cutting Services offer precision cutting with high-speed lasers, ensuring clean, accurate edges and intricate designs.

Takeaway Note:

AT’s ability to handle diverse project requirements makes them a preferred partner in the industry. However, the focus on rapid prototyping and short to medium runs may not fully cater to clients needing large-scale production capabilities.

4 Tips to Consider When Choosing Sheet Metal Forming Manufacturer in China

According to Business Sector Briefings, the sheet metal forming market is anticipated to grow at a CAGR of 1.4% during the forecast period of 2023-2029. This growth underlines the importance of choosing a manufacturer that is capable of adapting to the evolving industry landscape. Here are key considerations to help guide your decision:

- Precision and Quality of +/- 0.005 Inches Tolerance:Check the precision levels the manufacturer can achieve in sheet metal forming. For instance, look for a manufacturer that consistently delivers high-quality, precise sheet metal parts. This is essential for ensuring the parts you receive meet your specifications and quality standards.

- Capacity to Handle 10,000+ Units: Evaluate the manufacturer’s ability to handle high-volume production. It’s important to choose a manufacturer that can comfortably meet your volume requirements without a drop in quality, especially if you need large quantities of sheet metal parts.

- Advanced Technology with Biennial Updates: Consider the technology and equipment the manufacturer uses. Manufacturers who invest in the latest metal forming trends and regularly update their equipment are more likely to produce high-quality parts and adapt to evolving manufacturing demands.

The table below showcases the significance of adopting the latest technology and equipment in metal forming:

| Technology/Equipment | Benefit | Impact on Quality and Adaptability |

| 3D Printing for Prototyping | Rapid prototyping, design flexibility | Enhances part accuracy, reduces lead time |

| Laser Cutting Machines | Precision cutting, reduced material waste | Improves part precision, material efficiency |

| High-Speed Presses | Increased production speed | Boosts throughput, meets market demand quickly |

| Automated Quality Control | Consistent, precise quality inspection | Ensures high-quality parts, reduces errors |

| Robotics and Automation | Improved efficiency, reduced labor costs | Increases adaptability, supports complex tasks |

- Turnaround Times with 2-4 Weeks Standard: Assess the typical turnaround times for sheet metal forming projects. For example, choose a manufacturer that offers reasonable and reliable turnaround times, ensuring that you receive your orders within a timeframe that supports your business operations and project timelines.

Conclusion

It can be challenging to find a sheet metal forming manufacturer that truly meets your business needs. Zemetal stands out by offering high-quality, reliable solutions that can help resolve any production issues you might face.

In conclusion, this guide has introduced you to the top 7 sheet metal forming manufacturers, helping you compare their strengths and specialties. By choosing the right partner, you can improve your operations and save time. Contact us today to learn how we can take your projects to the next level.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.