Has anyone ever wondered how the most complex metal parts maintain such precise dimensions in high-volume production? The secret lies in the blanking process, a critical step in sheet metal fabrication.

With years of expertise in the sheet metal industry, our insights into the blanking process are derived from hands-on experience and deep technical knowledge.

Blanking is a metalworking process involving cutting a metal workpiece into a predetermined shape, a foundational step in creating high-quality metal components.

In this ultimate guide, you will discover the 6 key steps in the blanking process that are essential for achieving high precision in sheet metal products.

Read on to unlock more!

Step#1 Material Selection for Blanking

To begin the blanking process, selecting the right material is crucial for ensuring the desired quality and efficiency. Here are the essential steps in material selection:

- Assessing Material Thickness: The thickness of the material directly impacts the blanking process. Thicker materials require more force for cutting but offer greater durability. It’s important to balance material strength with the required force to achieve efficient and precise cuts.

- Considering Material Type: Different metals, such as steel, aluminum, or brass, have unique properties that affect the blanking process. For instance, softer metals like aluminum are easier to cut but may deform more easily, while harder metals like steel require more force but offer higher precision and durability.

- Evaluating Smooth and Clean Finish: The surface finish of the material plays a significant role in the final product quality. Materials with a smooth, clean finish reduce the risk of imperfections in the blanked parts and ensure a higher quality outcome.

- Analyzing Material Grain Direction: The grain direction of the metal can influence the blanking process. Aligning the blanking direction with the grain can reduce wear on the tooling and improve the longevity and quality of the blanked parts.

The table below provides insights into how the grain direction of materials influences the blanking process, impacting aspects from tooling wear to cost efficiency:

| Aspect | Description |

| Grain Direction Influence | The direction of the grain in the metal significantly affects the blanking process. |

| Tooling Wear | Proper alignment with grain direction can reduce wear on the tooling. |

| Part Quality | Alignment with grain direction improves the overall quality of the blanked parts. |

| Longevity of Blanked Parts | Matching the blanking direction with the grain extends the longevity of blanked parts. |

| Cost Efficiency | Cost efficiency is enhanced due to reduced tool wear and improved part quality. |

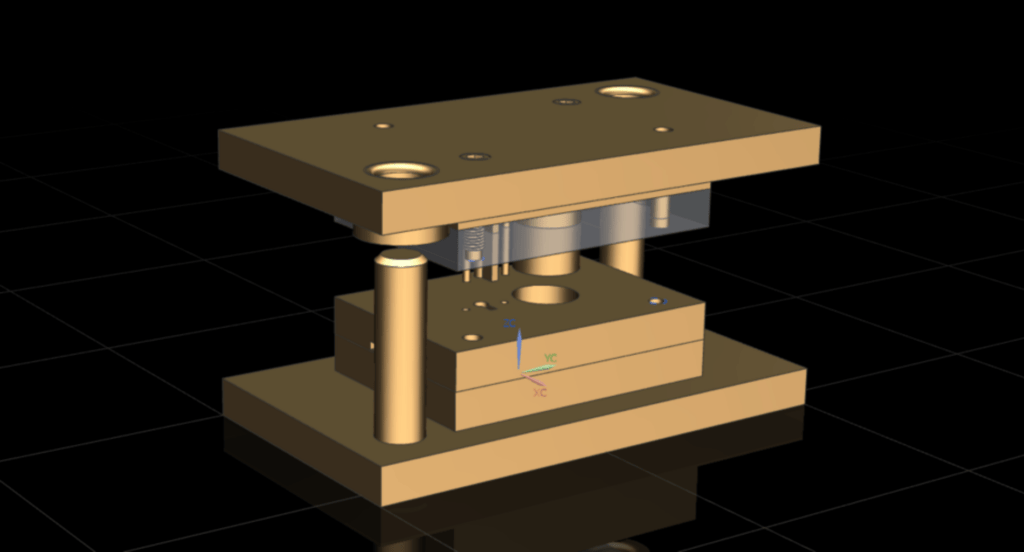

Step#2 Designing the Blanking Die

Following the careful selection of materials, the next pivotal step is designing the blanking die. Let’s break down the key considerations in this process:

- Determining Die Shape and Size: The shape and size of the die must precisely match the desired dimensions of the final product. Accurate measurements and design specifications are essential to ensure that the die produces components that meet exacting standards.

- Incorporating Clearances: Appropriate clearance between the punch and die is critical. This gap must be carefully calculated based on the thickness and type of material being used to prevent wear and tear on the die and ensure a clean cut.

- Incorporating Die Components: The design should include all necessary components such as punches, die blocks, and strippers. These elements should work harmoniously to facilitate easy ejection of the blanked part and maintain the integrity of the material during the process.

Step#3 Preparing the Sheet Metal

With the blanking die carefully designed, the focus shifts to preparing the sheet metal for the blanking process. Let’s see the essential steps involved in this preparation:

- Cleaning the Metal Surface: Before blanking, it’s crucial to clean the metal surface to remove any dirt, grease, or contaminants. This cleaning ensures a clean cut and prevents damage to the die, leading to a higher quality finished product.

- Applying Lubrication: Lubrication is key to reducing friction and wear during the blanking process. As per studies, over 50% of bearing failures are the result of improper lubrication. Zemetal’s services use specialized lubricants that not only protect the die but also help in achieving a smoother cut.

- Flattening and Leveling the Sheet: Ensuring the metal sheet is flat and level is important for uniform blanking. Any bends or distortions in the sheet can lead to inaccuracies in the final product. This step is crucial for maintaining consistent quality in the blanking process.

- Marking for Alignment: Accurate marking on the sheet metal for alignment with the die ensures precision in the blanking process. This step is critical for achieving the desired shape and dimensions in the final product.

Step#4 The Blanking Operation

After diligently preparing the sheet metal, we now arrive at the heart of the process: the blanking operation itself. We will explore the critical steps involved in executing this operation:

- Aligning the Sheet Metal: Proper alignment of the sheet metal with the die is crucial. The sheet must be positioned accurately to ensure that the cuts are made precisely according to the design. Misalignment, even by a small margin, can lead to defects in the final product.

- Executing the Cutting Stroke: The blanking press then delivers a cutting stroke. The die and punch work in tandem to exert a force sufficient to shear the metal, creating the desired shape. For example, when creating a circular blank, the die and punch must align perfectly to produce a clean and precise circle.

- Monitoring the Pressure and Speed: The pressure and speed of the blanking press need to be carefully monitored and adjusted according to the thickness and type of metal being used. Zemetal’s services always ensure a clean cut and prevent damage to the metal or the tooling.

Step#5 Inspection and Quality Control

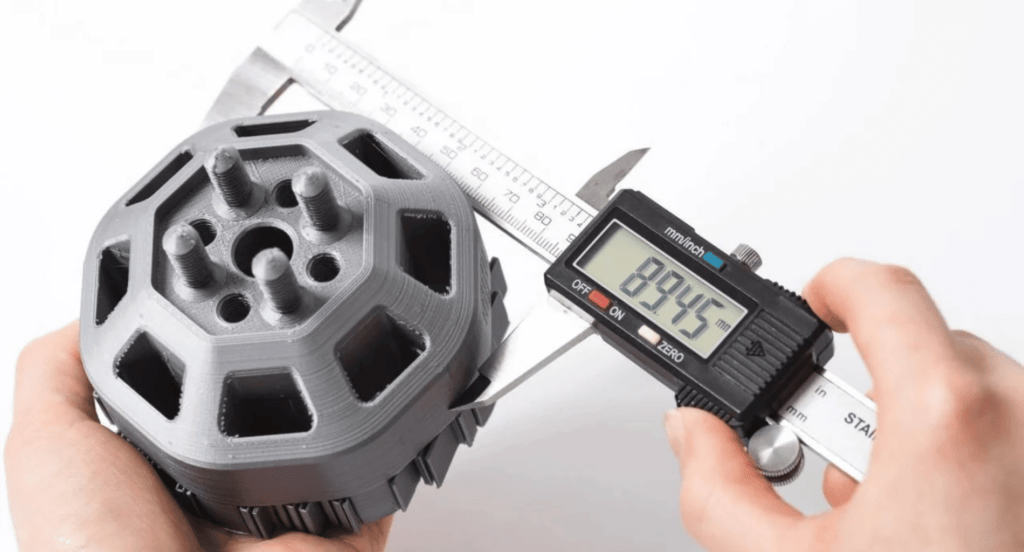

Following the completion of the blanking operation, the next critical phase is inspection and quality control. See the following key steps to ensure that every blank part meets the highest standards:

- Visual Inspection: The first step is a thorough visual inspection of each blanked part. Inspectors look for any signs of irregularities, such as burrs, deformations, or inaccuracies in shape. This step is crucial in identifying any immediate quality issues.

- Dimensional Accuracy Check: Using precision measuring tools, the dimensions of the blanked parts are checked against the specifications. For example, if a part is supposed to be 50mm in diameter, inspectors will use calipers to ensure this measurement is precise to the specified tolerance.

- Testing Material Properties: Depending on the application, various tests may be conducted to check the material properties such as hardness, strength, and grain structure. This ensures the part will perform as expected in its intended use.

- Documentation and Traceability: Maintaining detailed records of each batch of parts is crucial for traceability. This includes recording inspection results, machine settings, and material batches, allowing for accountability and quality assurance throughout the process.

Step#6 Post-Blanking Processes

After ensuring the quality and precision of the blanked parts, it’s time to focus on the post-blanking processes. Here are the essential steps that follow blanking:

- Deburring: The edges of the blanked parts often require deburring to remove any sharp or irregular remnants. This process is crucial for safety and for ensuring the parts fit well in their final assembly. For instance, an automated deburring machine can smooth out the edges of a circular blank.

- Secondary Machining: In some cases, additional machining processes like drilling or tapping are required to add features to the blanked parts. These processes are performed with precision to meet the exact design specifications of the final product.

- Surface Finishing: Surface treatments such as painting, powder coating, or anodizing may be applied to enhance the appearance and corrosion resistance of the parts. This step not only improves the aesthetic appeal but also extends the lifespan of the components.

- Final Inspection and Packaging: A final inspection is conducted to ensure that the post-blanking processes have been completed correctly. After passing this inspection, the parts are carefully packaged for shipping, with attention to preventing damage during transit.

Conclusion

In summary, understanding the 6 key steps in the electro-galvanizing process is essential for businesses aiming to ensure the highest quality and durability of their metal products. This guide serves as a valuable resource for achieving those standards.

For expert assistance in electro-galvanizing and other specialized metal services, consider Zemetal as your go-to partner. To explore our range of solutions and how they can benefit your business, contact us today.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.