Is your business harnessing the full potential of prototype laser cutting? This innovative technology is revolutionizing the way metal fabrication businesses approach their projects.

As an expert in the metal fabrication industry, I bring a wealth of knowledge and experience to the table, ensuring you get the most insightful and practical advice.

Prototype laser cutting stands for its ability to swiftly turn designs into high-quality prototypes, making it an indispensable asset for businesses looking to stay competitive and innovative.

In this article, you’ll learn about the fundamentals of prototype laser cutting, its benefits, applications, and how it can significantly impact your business operations.

Keep reading to discover the cutting-edge world of prototype laser cutting.

1. Understanding the Basics of Laser Cutting

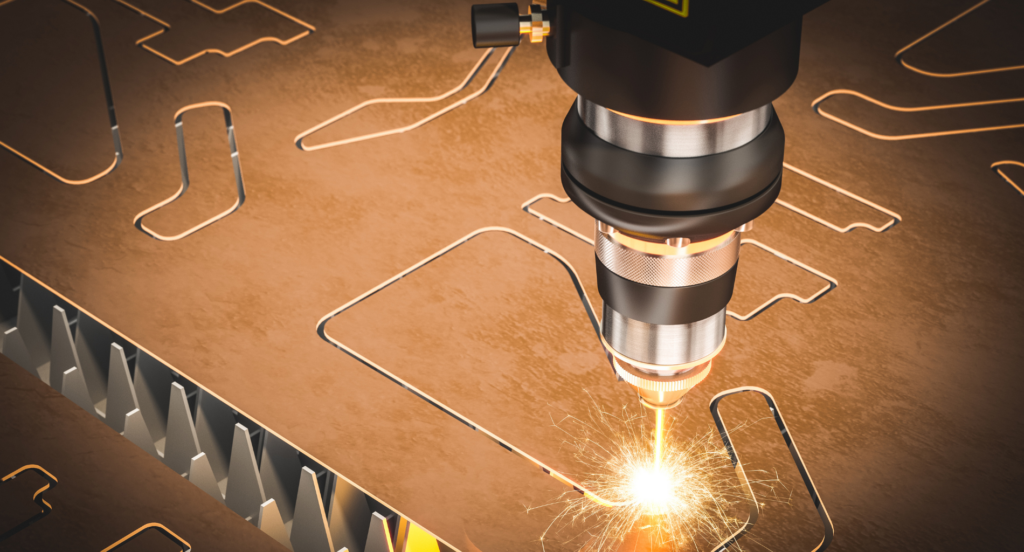

Laser cutting, a crucial technique in modern metal fabrication, achieves unmatched precision compared to traditional methods. It operates by directing a high-powered laser through a computer-controlled path to cut materials. This laser, focused on a small, intensely hot point, easily melts and vaporizes metal, ensuring clean, smooth cuts.

The process is largely automated, utilizing CNC programs for precise guidance along complex designs, making it perfect for projects needing intricate patterns and tight tolerances, ranging from delicate to industrial components. Reflecting its efficiency, the global laser cutting market, as reported by Grand View Research, is projected to expand at a compound annual growth rate (CAGR) of 5.5% from 2023 to 2030.

2. Benefits of Using Laser Cutting for Prototypes

Having explored the basic mechanics of laser cutting, it’s clear why this technology is a game-changer in the metal fabrication industry. Here are the specific advantages it provides, especially when it comes to creating prototypes:

Precision and Complexity

Laser cutting shines when precision is crucial. The technology allows for cuts with an incredibly fine level of detail, which is essential when creating prototypes that must be accurate representations of the final product. The laser’s pinpoint accuracy can produce complex geometries with ease. This means that even the most intricate designs can be prototyped, providing a true test of form and function.

Here’s a concise table highlighting the advantages of laser cutting for precision in prototyping:

| Advantage | Description |

| High Precision | Laser technology offers unparalleled accuracy, enabling intricate and precise cuts. |

| Complex Geometries | Capable of producing intricate and complex shapes or designs with exceptional accuracy. |

| Prototyping Efficiency | Enables the creation of accurate prototypes, validating both form and function effectively. |

| Fine Detailing Capability | Achieves incredibly fine details, crucial for prototypes to represent final product accuracy. |

| Versatile for Designs | Capable of handling a wide range of designs, ensuring even the most intricate can be prototyped. |

Speed and Efficiency

Time is a critical factor in product development, and laser cutting significantly accelerates the prototyping phase. For instance, since laser cutting is controlled by CNC machinery, the transition from a digital design to a physical prototype can be achieved remarkably quickly. This rapid turnaround not only speeds up the development cycle but also enables multiple iterations to be produced in a short span of time.

Cost-Effectiveness

Laser cutting is a cost-effective solution for prototyping due to its minimal setup requirements and the lack of need for hard tooling. The precision of laser cutting also reduces material waste, and its ability to produce accurate prototypes the first time around decreases the need for expensive reworks. By streamlining the prototyping process, businesses can allocate their resources more efficiently and get to market faster.

3. Innovations and Trends in Prototype Laser Cutting

The benefits of using laser cutting for prototypes are undeniable, and the technology continues to evolve. Here are some of the latest innovations and trends:

Automation and Software Advancements

The intersection of laser cutting technology with advanced software and automation has led to remarkable increases in precision and efficiency. Modern laser cutters are increasingly equipped with sophisticated sensors and adaptive control systems that can make real-time adjustments during the cutting process. This not only improves the quality of prototypes but also reduces the likelihood of errors.

Fiber Laser Technology

Fiber lasers are known for their exceptional beam quality, high energy efficiency, and ability to cut reflective metals that traditional CO2 lasers struggle with. This technology is particularly beneficial for prototyping applications where a wide range of materials is used, ensuring that businesses can prototype with the exact materials they intend to use in final production.

Eco-Friendly Cutting Solutions

Laser cutting technology is adapting to this trend with new, more eco-friendly options that consume less power and produce fewer emissions. At Zemetal, innovations such as improved cutting gases and refined beam delivery systems are helping to minimize the environmental impact of prototype laser cutting, making it a more sustainable choice for businesses conscious about their ecological footprint.

4. The Workflow of Laser Cutting in Prototype Development

Following the exploration of the latest trends in laser cutting technology, it becomes evident how these advancements refine the prototyping workflow. Here are the critical stages:

Step#1 Design and CAD Modelling

The first step in the laser cutting workflow involves translating ideas into precise digital models using computer-aided design (CAD) software. This step is foundational, as the CAD model serves as the blueprint for the laser cutter’s path. Designers must ensure that the model is accurate and optimized for laser cutting, taking into consideration factors like kerf (the width of the cut) and the properties of the material to be used.

Step#2 Programming the Laser Cutter

Once the design is finalized, the next step is programming the laser cutter. This involves setting up the correct parameters in the CNC machine that controls the laser, such as cutting speed, power, frequency, and gas flow. The precise programming ensures that the laser cutter follows the CAD design to the letter, which is essential for producing an accurate prototype.

Step#3 Material Selection and Preparation

Selecting the right material for the prototype is crucial, as it needs to mimic the characteristics of the final product as closely as possible. At Zemetal, once chosen, the material is prepared for cutting, which may include cleaning, drying, and securing it to the cutting bed. Proper material preparation ensures the highest quality cut and helps to avoid any potential issues during the cutting process.

Step#4 Laser Cutting and Quality Control

With the design modeled, the cutter programmed, and the material prepared, the laser cutting can commence. As the laser moves along the programmed path, it slices through the material with precision, creating the prototype component. Each piece undergoes a thorough quality control check. This step ensures that every prototype meets the strict tolerances and quality standards required before it moves on to assembly or testing.

5. Applications of Laser Cutting in Prototyping

Understanding the workflow of laser cutting in prototype development can significantly enhance our appreciation of its vast applications across different sectors. Here are the industries where laser cutting is playing a transformative role:

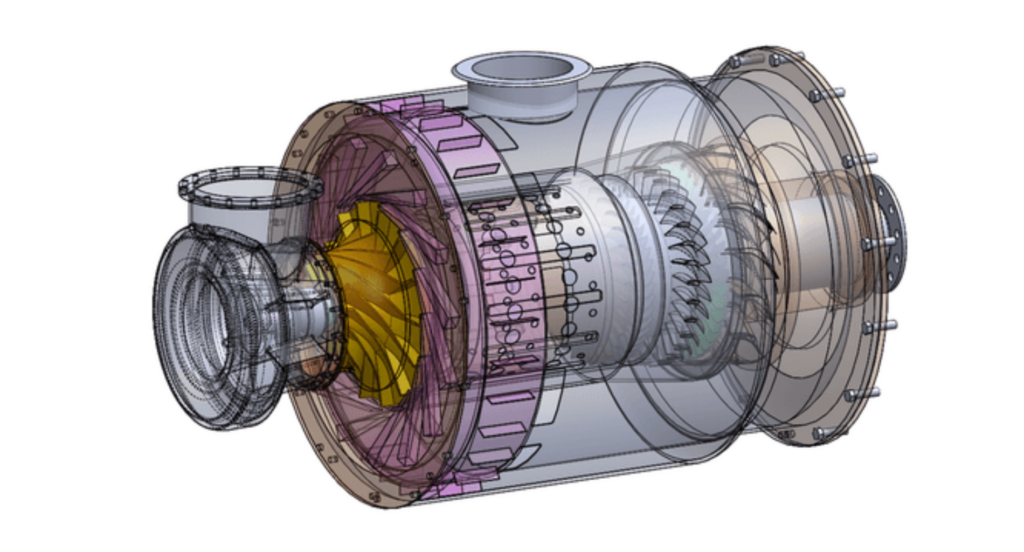

Aerospace and Automotive

In industries like aerospace and automotive, laser cutting is invaluable. Prototyping components for vehicles and aircraft requires exact tolerances and the ability to work with a wide range of materials. Laser cutting meets these needs by providing the accuracy necessary for safety-critical parts and the versatility to handle different materials, from lightweight aluminum alloys to high-strength steels.

Medical Device Manufacturing

According to Thunder Laser, the high precision of laser cutting is ideal for creating components of surgical instruments, implants, and other devices that must adhere to stringent regulatory standards. For instance, the ability to rapidly prototype these components accelerates the development process and ultimately speeds up the time-to-market for life-saving medical innovations.

Electronics and Semiconductor

Laser cutting is also instrumental in the prototyping stages of the electronics and semiconductor industries, where miniaturization continues to push the boundaries of how small and efficient devices can be. Prototyping with laser cutting allows for the precise fabrication of components like circuit boards, enclosures, and connectors.

6. Comparing Laser Cutting to Traditional Prototyping Techniques

In reflecting on the diverse applications of laser cutting technology, it’s beneficial to contrast it with traditional prototyping techniques to understand its advantages and potential limitations. Here are the key comparisons:

Laser Cutting vs. Milling

Milling has been a fundamental method in prototyping, known for its robustness and versatility. However, laser cutting surpasses milling in terms of precision and speed for certain applications. While milling can handle a wide range of materials, the mechanical nature of the process can lead to longer setup times and slower production speeds compared to the rapid, non-contact nature of laser cutting.

Laser Cutting vs. Waterjet Cutting

Waterjet cutting is praised for its ability to cut through very thick materials without introducing heat-induced distortions. However, laser cutting offers greater precision, especially for thin or medium-thickness materials. The speed of laser cutting is typically faster than waterjet for complex shapes or fine details due to the focused nature of the laser beam.

Laser Cutting vs. Die Cutting

Die cutting is a traditional prototyping method that is effective for high-volume production but less adaptable for prototyping due to the high costs and lead times. Laser cutting, in contrast, requires no hard tooling, allowing for modifications to be made quickly and inexpensively. It excels over die cutting with its ability to produce small batch sizes economically and to handle more complex designs without the need for multiple dies.

7. Challenges and Limitations of Laser Cutting in Prototyping

Following the comparison between laser cutting and traditional prototyping methods, it’s important to delve into the specific challenges that come with using laser cutting in the prototyping phase. Here are some of the primary challenges:

Challenges

- Complex 3D Shapes: Laser cutters excel at cutting flat materials, but they are not well-suited for creating complex 3D shapes that require multiple cutting angles or undercuts.

- Kerf Precision: While laser cutting is precise, the kerf width can vary slightly depending on the material and the condition of the laser, which may require adjustments in the design to ensure parts fit together properly.

- Limited Size: The size of the prototype that can be laser cut is limited by the size of the laser cutting bed; larger prototypes may require sectioning and assembly post-cutting.

Limitations

- Heat Sensitivity: Certain materials that are sensitive to heat can warp or become distorted during the laser cutting process.

- Material Diversity: Not all materials can be laser cut; for example, very thick metals or certain types of plastics may be unsuitable for laser processing.

- Toxic Fumes: Cutting some materials, particularly certain plastics, can produce toxic fumes that require adequate ventilation systems to ensure safety.

8. 4 Tips for Effective Laser Cutting in Prototyping

In light of the challenges and limitations that can arise with laser cutting in prototyping, it’s crucial to employ strategies that enhance the effectiveness of this technology. Here are some essential tips:

#1 Understand Material Properties

Research and select the appropriate materials for laser cutting, considering factors like thickness, reflectivity, and thermal properties to minimize issues such as warping or inefficient cuts.

#2 Optimize Design for Laser Cutting

Simplify designs to reduce unnecessary complexity while maintaining the integrity of the prototype, ensuring that cuts are clean and precise. Include kerf compensation in your design files to account for the material that will be vaporized by the laser.

#3 Utilize CAD and Nesting Software

Employ computer-aided design (CAD) software to create precise and detailed designs that can be directly translated into laser cutter instructions. Take advantage of nesting software to maximize material utilization and minimize waste.

#4 Regular Maintenance and Calibration

Keep the laser cutting equipment well-maintained and regularly calibrated to ensure consistent quality and precision in your prototypes. Schedule routine inspections and cleanings to prevent issues such as lens contamination or misalignment.

Conclusion

Prototype laser cutting is more than just a manufacturing technique; it’s a strategic tool that can propel businesses into new realms of efficiency and innovation. By embracing this technology, metal fabrication businesses can stay ahead in a competitive market, ensuring precision and quality in their products.

For those looking to integrate prototype laser cutting into their operations, Zemetal offers top-tier metal fabrication services. Contact us today and explore how we can transform your production processes.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.