Are you curious about how laser engraving aluminum can transform your product’s appeal? This technology is transforming how details and precision are achieved in metal fabrication.

With extensive industry knowledge and a commitment to providing reliable, cutting-edge information, we offer valuable insights into laser engraving aluminum, essential for businesses seeking to navigate the evolving landscape of this advanced technology.

Laser engraving on aluminum showcases the remarkable progress of technology, blending artistry with functionality. Its application signifies a step towards innovation and quality in fabrication processes.

In this guide, we dive into the technicalities, advantages, and creative possibilities unlocked by laser engraving on aluminum, providing insights crucial for industry leaders.

Read on to explore this transformative technology.

1. The Basics of Laser Engraving on Aluminum

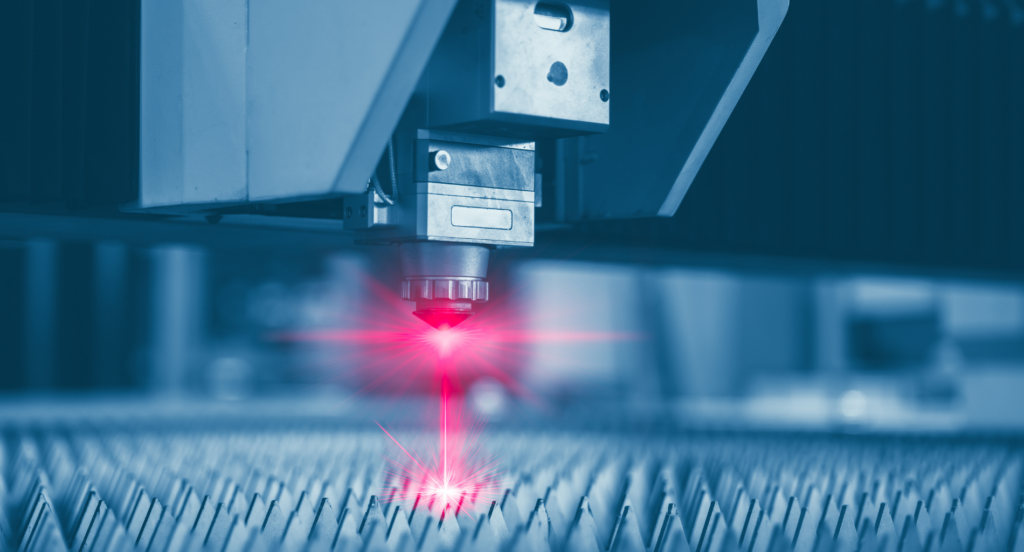

Laser engraving on aluminum utilizes high-powered lasers to etch detailed designs onto aluminum surfaces, offering a blend of precision and aesthetic appeal. This method is particularly effective due to aluminum’s properties, which respond well to the laser, allowing for detailed patterns and markings. The process involves directing a focused laser beam to accurately shape and remove material from a surface.

Aluminum’s suitability for laser engraving is due to its durability and the exceptional finish that can be achieved. Unlike other engraving methods, laser engraving offers a non-contact solution, which means there is minimal wear and tear on the tools and the material itself. This aspect ensures a high-quality finish, and contributes to the longevity and reliability of the engraved product.

2. Advantages of Laser Engraving for Businesses

Building on the basics of laser engraving on aluminum, it’s important to understand how this technique directly benefit businesses, making it a valuable asset. Here are the key advantages:

- Cost-Effectiveness: Laser engraving stands out for its cost efficiency. It minimizes material waste and eliminates the need for expensive tooling, making it a cost-effective choice for both small and large-scale productions.

- Precision and Quality: The precision of laser engraving ensures unmatched quality, crucial for businesses that strive for excellence. This method allows for detailed and accurate reproductions, essential for high-quality product outputs.

- Efficiency and Speed: Laser engraving is known for its efficiency and speed, making it a preferred choice for businesses with tight production schedules. The quick turnaround times enable companies to meet demanding deadlines without compromising on quality.

- Branding and Customization: Laser engraving serves as a powerful tool for branding and customization, enabling businesses to etch logos, taglines, and other distinctive designs onto their products. This enhances brand identity and adds value to the customer experience.

3. Types of Lasers Used in Engraving Aluminum

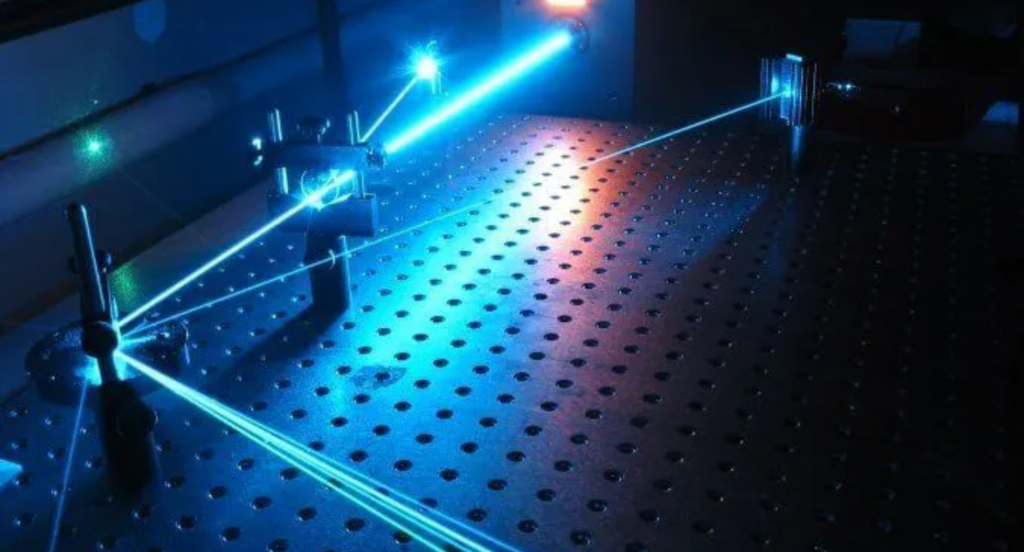

Building on the advantages laser engraving offers businesses, it’s crucial to understand the types of lasers that make these benefits possible. Here are the key laser types used in aluminum engraving:

CO2 Lasers

CO2 lasers, renowned for their versatility and precision, are widely used in engraving, including aluminum. They’re efficient and ideal for detailed designs in both creative and industrial settings. Precision Business Insights reports that the CO2 laser market is set to grow at a 4.7% CAGR from 2023 to 2029, driven by the demand for high-output power lasers in steel processing.

Fiber Lasers

Fiber lasers stand out for their precision and speed, making them highly suitable for industrial engraving tasks. These lasers are particularly effective on metals like aluminum, offering a combination of fine detailing and rapid processing. Their strength and low maintenance requirements make them a practical choice for continuous, high-volume operations.

Nd:YAG Lasers

Nd:YAG lasers are valued for their adaptability to a wide range of materials and engraving depths. They are especially effective for deep engraving tasks on aluminum, providing sharp and clear outcomes. Their high-intensity beam is ideal for applications requiring strong contrast and durability.

UV Lasers

UV lasers excel in high-precision, low-impact engraving, making them ideal for delicate or thin aluminum materials. They provide fine detailing with minimal thermal effects, preserving the integrity of the material. UV lasers are perfect for applications that require detailed designs and a high-quality finish without changing the material’s properties.

4. Techniques for Effective Laser Engraving on Aluminum

Following the exploration of various laser types, understanding the effective techniques for laser engraving on aluminum is crucial for achieving the best results. Here are key techniques to employ:

Surface Preparation

The foundation of a successful laser engraving process on aluminum begins with thorough surface preparation. This involves meticulously cleaning the aluminum to remove any dirt, oils, or contaminants that might interfere with the laser’s ability to produce a clean, sharp image. Additionally, smoothing out the surface minimizes engraving irregularities for higher-quality laser outcomes.

Parameter Optimization

Optimizing the laser’s parameters is delicate yet crucial in the laser engraving on aluminum. It involves carefully adjusting the laser’s settings such as power, speed, and focus to suit the specific type of aluminum being used, which can vary in thickness and reflectivity. This fine-tuning is essential for achieving precise engraving depth and clarity without causing material damage like burning or heat marks.

Cooling Techniques

Cooling techniques are an integral part of laser engraving on aluminum, essential for preserving the material’s integrity and quality. For example, effective cooling methods, such as air-assisted cooling or coolant fluids, are utilized to prevent heat-related issues, such as warping or changes in metal properties caused by laser heat, especially crucial when working with thin or delicate aluminum pieces to maintain engraving precision.

5. Design Possibilities with Laser Engraved Aluminum

Transitioning from the techniques, the shift focuses on design possibilities with laser engraved aluminum revealing a wide range of creative and functional applications. Here are design concepts that can be achieved:

Geometric Patterns

Laser engraving allows for the creation of precise and detailed geometric patterns on aluminum. These designs can range from simple grids to complex fractal patterns, offering a modern and sophisticated appearance. Such patterns are perfect for adding a contemporary touch to both functional and decorative items.

Nature-Inspired Motifs

Incorporating nature-inspired motifs, such as floral designs or animal patterns, is a popular trend in laser engraved aluminum. These motifs can be delicately etched to create a sense of elegance and organic beauty. This approach is especially appealing for decorative pieces and lifestyle products that seek to bring an element of nature into their design.

Textured Finishes

Laser engraving can create varied textured finishes on aluminum, giving a tactile dimension to the designs. From smooth, subtle etchings to more pronounced, rough textures, these finishes can significantly change the look and feel of a product. Textured finishes are ideal for enhancing grip on tools or adding a unique visual appeal to consumer goods.

This table details the various types of textured finishes achievable through laser engraving on aluminum, highlighting their specific applications and effects on product aesthetics and functionality.

| Texture Type | Description | Application |

| Smooth Etching | Light, subtle texture for a refined appearance | Suitable for decorative consumer goods |

| Rough Texture | More pronounced, tactile finish | Ideal for enhanced grip on tools |

| Matte Finishing | Non-reflective, understated surface | Perfect for a sleek, modern look |

| 3D Texturing | Creates a three-dimensional effect on surfaces | Adds depth and visual interest |

| Patterned Design | Custom patterns for unique visual appeal | Used for branding or artistic elements |

Abstract Art

Abstract art designs lend a creative and avant-garde edge to aluminum items. Laser engraving can be used to etch abstract patterns, shapes, and lines, offering an artistic touch that appeals to modern aesthetics. This style is particularly suited for products targeting a niche market or seeking to stand out with a unique design language.

6. Applications of Laser Engraved Aluminum

Beyond design possibilities, exploring the practical applications of laser engraved aluminum reveals its versatility. Here are some of the key areas where this technology is making a significant impact:

Industrial Applications

In the industrial sector, laser engraved aluminum is essential for creating durable, legible labels and identification tags on machinery and equipment. This method ensures long-lasting markings that withstand harsh conditions, making it ideal for safety signage and operational instructions in manufacturing environments.

Consumer Electronics

The consumer electronics industry utilizes laser engraved aluminum for branding and customization of devices like smartphones and laptops. This technique adds a touch of elegance and uniqueness to each product, enhancing both the aesthetic appeal and the perceived value in the eyes of consumers. Zemetal’s laser engraving capabilities play a vital role in elevating these products, setting a new standard in the market.

Architectural Elements

In architecture, laser engraved aluminum is known for its ability to add complex, detailed designs to both exterior and interior elements. For example, its durability and resistance to environmental factors make it ideal for creating striking building facades, elegant signage, and unique decorative accents. This technology combines appearance with usefulness, making architectural spaces look better and more functional.

7. Common Challenges and Solutions in Laser Engraving Aluminum

The exploration of laser engraved aluminum applications naturally leads to addressing the challenges encountered in its process. Here are the key challenges and their effective solutions:

Material Handling

During laser engraving, aluminum’s lightness can cause movement, affecting precision. The solution involves using custom-designed jigs and fixtures that firmly secure the aluminum during engraving. This approach maintains the material’s position, ensuring accurate and consistent engraving results.

Reflectivity Issues

Aluminum’s shiny surface can cause laser beams to bounce off, resulting in uneven engraving. To overcome this, specific laser types better suited for reflective surfaces should be utilized and apply a pre-engraving coating to reduce reflectivity. This preparation allows the laser to interact more effectively with the aluminum surface, resulting in clearer engravings.

Surface Irregularities

Irregularities on the aluminum surface can disrupt the uniformity of the engraving. Pre-processing techniques, such as applying a smooth anodizing layer or polishing the surface, can create a more consistent engraving area. These ensure that the laser engraves evenly across the entire surface, enhancing the quality of the final product.

Heat Management

The intense heat generated during laser engraving can cause distortion in aluminum. Implementing effective heat management strategies, such as using lower laser power settings and incorporating cooling systems, can prevent material warping. This ensures the structural and aesthetic integrity of engraved aluminum is maintained.

8. Evolving Trends and Future of Laser Engraving in Metal Fabrication

After addressing the common challenges, exploring the world of laser engraving on aluminum reveals a dynamic environment with emerging trends and exciting possibilities. Here are the key developments shaping this field:

Adoption of AI and Machine Learning

The integration of artificial intelligence (AI) and machine learning in laser engraving systems is a game-changer. This incorporation improves engraving accuracy, adapts to materials, and offers predictive maintenance for longer equipment lifespans with less downtime. Zemetal harnesses these technologies to enhance precision and efficiency in engraving processes.

Focus on Eco-Friendly Techniques

Sustainability is increasingly gaining significance in the metal fabrication sector, and laser engraving is no exception. Modern laser engraving methods are becoming more energy-efficient and minimizing waste, aligning with global sustainability goals. This shift is not only beneficial for the environment but also appeals to the increasing market segment that values eco-conscious manufacturing practices.

Collaborative Robotics in Engraving

The field is witnessing a surge in the use of collaborative robots (cobots) in laser engraving. These cobots are designed to work alongside human operators, enhancing the engraving process with their precision and repeatability. The collaboration between human skill and robotic efficiency is creating a more dynamic, flexible, and productive working environment.

Conclusion

Laser engraving on aluminum offers a transformative approach to metal fabrication, blending precision with creativity. This guide aims to equip you with comprehensive knowledge and practical techniques, enhancing your operations and product quality.

If you are looking to utilize the full potential of laser engraving, Zemetal is your go-to resource. Contact us for state-of-the-art solutions and expert guidance.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.