How does laser engraving work? It’s a process that uses high-powered lasers to etch designs or text onto materials with remarkable precision, making it perfect for detailed work.

As an interior designer, I often get asked about how laser engraving can create custom patterns on metals, wood, and other surfaces for unique design projects.

Don’t worry, the process is easy to understand and highly effective for creating intricate and long-lasting designs.

In this guide, you will learn how laser engraving works, its various applications, and why it has become a go-to method for precision detailing in many industries. By understanding the process, you’ll see how it can elevate the quality and creativity of your projects.

So, here we go!

1. Understanding the Basics of Laser Technology

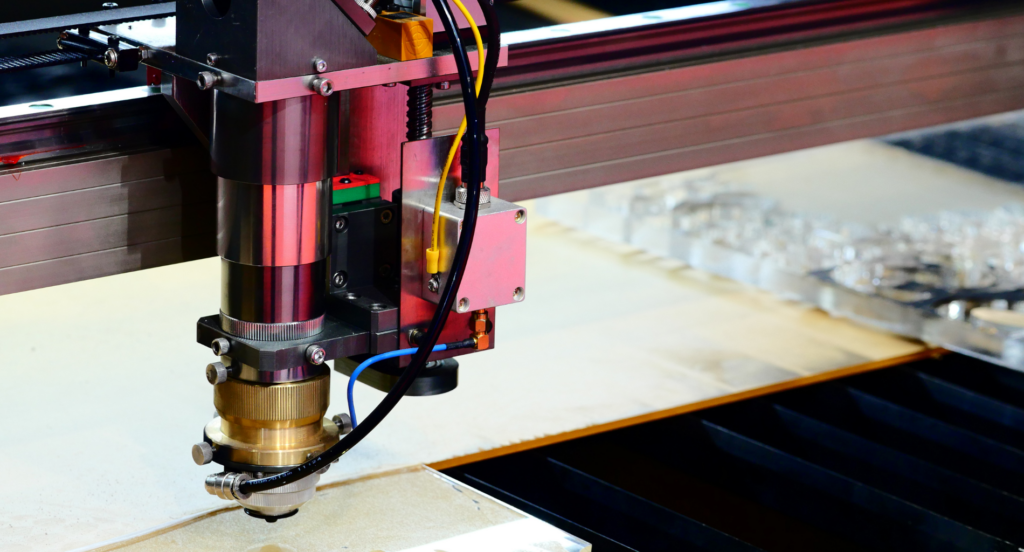

Laser technology, at its core, is centered around the generation and manipulation of highly focused beams of light. In laser engraving, this technology is finely tuned to interact with material surfaces. The laser beam, generated from a source, is directed onto the material through a series of mirrors and a focusing lens, concentrating the light into a precise, high-energy point.

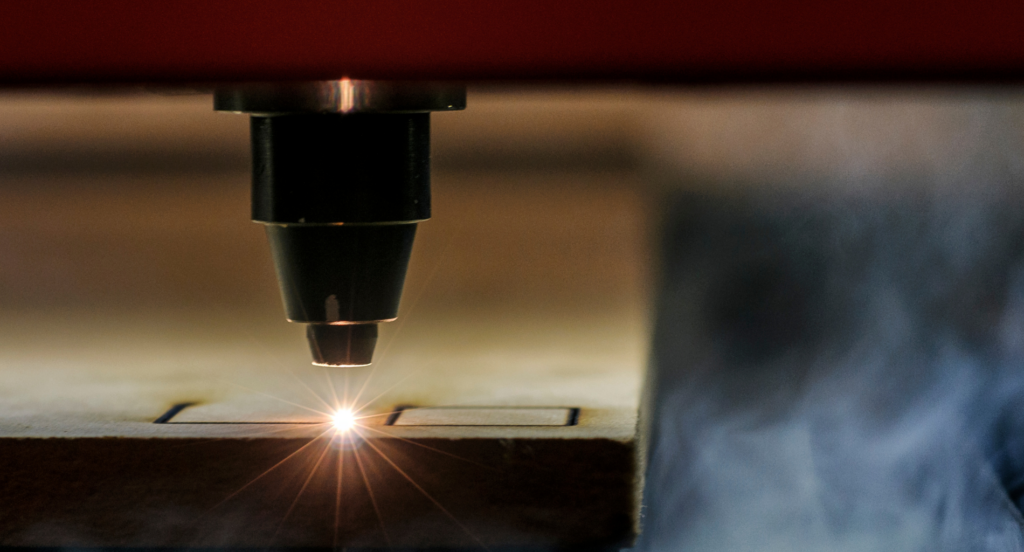

This concentrated beam, when applied to a material surface, induces a controlled form of physical or chemical change. In the context of metal fabrication, the laser effectively vaporizes the surface layer of the material, creating an engraved pattern or design. From intricate artistic designs to precise industrial markings, the adaptability of laser technology makes it an invaluable tool in the realm of metal fabrication.

2. The Science Behind Laser Engraving

Building upon our understanding of laser technology’s basics, let’s delve deeper into the scientific principles powering laser engraving. Here are the intricate scientific details that make laser engraving a standout technique in metal fabrication:

Laser Generation and Properties

This process typically uses a medium like CO2, fiber, or crystal, energized by electricity or another light source. The energized medium then emits photons, creating a focused beam of light with unique properties – coherence, collimation, and high intensity. These are crucial as they allow the laser to concentrate large amounts of energy onto a very small area, making precise and clean cuts or engravings on various materials.

This table summarizes the key types of laser generation mediums and their properties:

| Laser Type | Medium | Properties | Applications |

| CO2 Laser | Carbon Dioxide | High power, good for thick material cutting | Ideal for wood, acrylic, and fabric |

| Fiber Laser | Doped Fiber | High precision, excellent for metals | Perfect for metal cutting and engraving |

| Crystal Laser | Nd:YAG or Yb:YAG | High intensity, versatile applications | Used in medical and manufacturing fields |

| Diode Laser | Semiconductor | Compact, lower power | Suitable for hobbyist and light engraving |

| Green Laser | Frequency-Doubled | Visible light, high precision | Ideal for high-contrast marking on metals |

Material Interaction and Engraving Process

When the laser beam contacts a material, it induces a localized increase in temperature. For instance, in metal fabrication, the intense heat usually causes the metal to vaporize or undergo a color change, creating the desired engraving. The process’s precision is governed by factors like laser power, speed, and focus, which can be finely tuned to achieve different depths, textures, and detailing in the engraving.

Control and Manipulation of Laser Beams

Controlling the laser beam is crucial for precise engravings. At Zemetal, this is typically achieved through a combination of mirrors and lenses, which direct and focus the laser onto the material’s surface. Modern laser engraving machines often incorporate computer-controlled systems, allowing for intricate designs and patterns to be engraved with high accuracy.

3. The Laser Engraving Process Explained

After exploring the scientific foundations of laser engraving, we now turn to the practical aspects of how this process unfolds step by step. Here are the essential stages of the laser engraving process:

#1 Design Creation and Transfer

The first step in the laser engraving process is the creation of the design to be engraved. At Zemetal, this design is usually created or modified using computer-aided design software, allowing for intricate details and precision. The design is transferred to the laser engraving machine’s control system. This system interprets the design as a set of instructions, dictating the laser’s path, intensity, and speed during the engraving process.

#2 Material Preparation and Positioning

Before the engraving begins, the material to be engraved needs to be properly prepared and positioned. This involves cleaning the surface to ensure it’s free from any contaminants that could affect the engraving quality. The material is then placed into the laser engraver, secured firmly to prevent any movement during the engraving process.

#3 Laser Engraving Execution

With the design loaded and the material in place, the laser engraving process can commence. The laser engraver directs the laser beam onto the material’s surface, following the pattern set out in the design instructions. As the laser moves across the material, it vaporizes or alters the surface to create the desired engraving.

#4 Post-Engraving Processes and Quality Control

After the engraving is complete, there are often post-processing steps to enhance the finished product. This may include cleaning to remove any residue or debris from the engraving process. Quality control checks are also essential, ensuring that the engraving meets the required specifications and quality standards. Any necessary adjustments are made during this stage to ensure the final product is of the highest quality.

4. Applications of Laser Engraving in Different Industries

Transitioning from the detailed laser engraving process, we now examine how this technology is applied across various industries. Here are some key areas where laser engraving is making a significant impact:

Manufacturing and Industrial Applications

In the manufacturing industry, laser engraving plays a crucial role by providing durable and precise markings on industrial components. The significance lies in its ability to produce markings that remain legible in harsh environments, ensuring traceability and quality control. Reflecting this importance, the global laser engraving market is on the rise. According to Research Reports World, it is projected to grow with a CAGR of 6.93%.

Art and Design Industry

The art and design industry reaps significant benefits from laser engraving, using it to produce intricate artworks and decorative items. Artists and designers utilize laser engraving to work on a variety of materials, including wood, glass, acrylic, and even leather, creating detailed patterns, texts, and imagery. This technology offers a high degree of precision and consistency, enabling artists to replicate complex designs with ease.

Medical and Healthcare Industry

In the medical and healthcare industry, laser engraving plays a critical role in enhancing patient safety and equipment traceability. For instance, surgical tools, implants, and medical devices are often engraved with crucial information like serial numbers, manufacturer details, and patient identification data. This permanent marking method ensures that information remains readable even after repeated sterilization processes.

5. Future Trends and Innovations in Laser Engraving

With the diverse applications of laser engraving in mind, let’s look forward to the emerging trends and innovations shaping its future. Here are the anticipated advancements in laser engraving technology:

Enhanced Precision and Speed

According to Engineering Manufacturing, one of the most exciting trends in laser engraving is the continuous improvement in precision and speed. Future laser engravers are expected to harness advanced optics and more refined control systems, allowing for even finer detail in engravings. This will not only enhance the quality of the finished product but also significantly reduce the time taken for each engraving.

Integration with Artificial Intelligence and Automation

Artificial Intelligence and automation are set to play a significant role in the evolution of laser engraving. AI-driven algorithms could optimize engraving patterns for better quality and efficiency, while automated systems could handle material loading, positioning, and even post-processing tasks. This integration will likely lead to smarter, more autonomous laser engraving systems capable of adapting to different materials and designs.

Expanded Material Compatibility and Applications

Innovations in laser technology could enable engraving on materials previously considered challenging. Additionally, we might see laser engraving being applied in new industries, such as renewable energy (for solar panel marking) or environmental conservation (for eco-friendly branding and labeling solutions). These advances will open up new markets and opportunities for laser engraving technology.

Conclusion

If you’re struggling with creating detailed, permanent markings on metal or other materials, laser engraving might be the perfect solution. Its precision and ability to work with various surfaces make it an invaluable tool. At Zemetal, we specialize in using advanced laser technology to provide the accuracy and quality you need.

In conclusion, this guide has walked you through how laser engraving works and why it’s a highly effective process for detailed engraving. With this understanding, you can see how it can benefit your projects. Contact us today to learn how Zemetal can help you achieve the results you’re looking for with laser engraving.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.