Is your business contemplating the choice between powder coating and paint for your metal finishes? This crucial decision impacts not just aesthetics, but also durability and cost-efficiency.

As a metal fabrication expert, I bring years of experience and a deep understanding of both techniques to guide you through this comparison.

Powder coating, known for its durability, stands out in industrial applications. Paint, on the other hand, provides versatility in color and finish, but may lack the robustness needed for certain environments.

This article will delve into the technicalities, benefits, and drawbacks of powder coating versus paint, helping you make an informed decision for your business needs.

Keep reading to uncover more about these metal finishes.

1. Brief Overview of Metal Finishing Techniques

Metal finishing techniques are diverse processes used to enhance the surface of metal products, impacting their appearance, durability, and resistance to corrosion. Common methods include electroplating, anodizing, and powder coating. Electroplating involves coating the metal with a thin layer of another metal through an electrochemical process.

Anodizing, typically used for aluminum, enhances corrosion resistance and surface hardness. Powder coating, on the other hand, applies a protective and decorative finish using dry powder, which is then cured under heat to form a skin. Zemetal recognizes that each method serves distinct purposes and is chosen based on the desired properties of the finished product.

2. Understanding Powder Coating

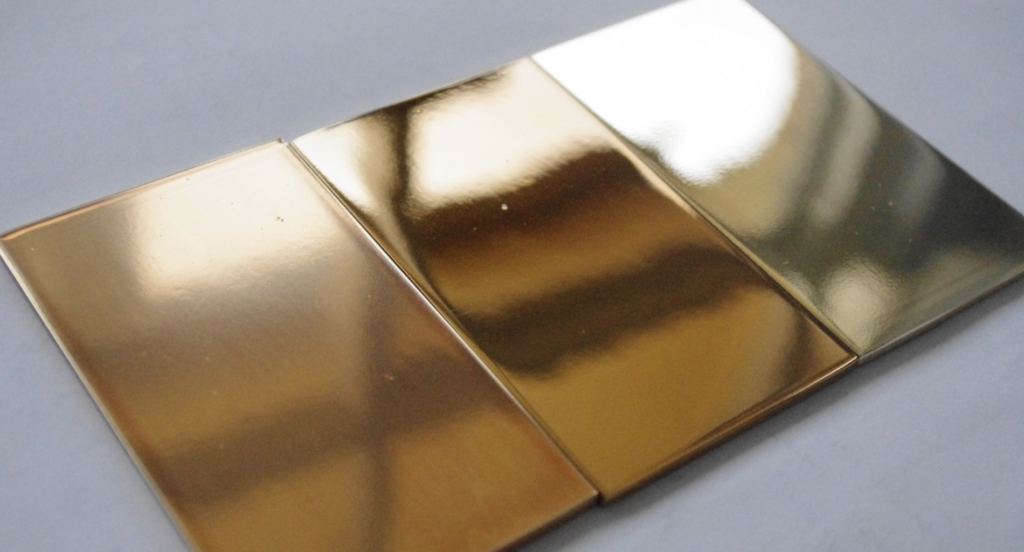

Powder coating is a distinguished metal finishing technique known for its durability and adaptability. Zemetal capitalizes on the extensive range of aesthetic choices powder coating offers, including a wide variety of colors and finishes. Market research by Research Nester predicts that the Powder Coatings Market will surpass USD 36 Billion by 2036, growing at a 7% CAGR, highlighting its increasing relevance and acceptance in the industry.

Benefits of Powder Coating

- Durability: Powder coatings provide a thick, hard finish that is more resistant to chipping, scratching, and wear than traditional paint coatings.

- Environmental Impact: This process emits fewer volatile organic compounds (VOCs), making it more environmentally friendly compared to conventional liquid coatings.

- Aesthetic Variety: Offers a vast array of colors and finishes, enabling customization and enhanced visual appeal for various applications.

Disadvantages of Powder Coating

- Cost: Initial setup and equipment costs for powder coating are typically higher than for conventional liquid painting.

- Limitations on Materials: Powder coating is mainly suitable for metal surfaces and may not be applicable to other materials like plastic or wood.

- Complexity in Color Changes: Changing colors during the powder coating process can be more time-consuming and complex compared to liquid painting.

3. Exploring Paint as a Metal Finish

Painting is a traditional and widely used method, known for its versatility and range of options in colors and textures, according to Just Paint. It involves applying liquid paint, which is a mixture of pigment, binder, and solvent, to a metal surface. This method is particularly favored for its ability to provide a vast spectrum of colors, allowing for more customization and design flexibility compared to other finishing techniques.

Benefits of Painting Metal

- Aesthetic Flexibility: Allows for an extensive variety of colors and textures, offering more customization options.

- Ease of Application: Liquid paint can be easily applied to various surfaces and requires simpler equipment and processes.

- Cost-Effectiveness: Generally, painting is more cost-effective in terms of initial investment compared to methods like powder coating.

Disadvantages of Painting Metal

- Reduced Durability: Painted surfaces are less resistant to physical damage like chipping and scratching.

- Environmental Impact: The use of solvents in paint contributes to the emission of VOCs, posing environmental concerns.

- Fading and Weathering: Paint is more susceptible to fading and deterioration under harsh weather conditions and prolonged use.

4. Comparative Analysis: Powder Coating vs. Paint

After understanding the basic principles of both powder coating and paint as metal finishes, it’s essential to delve into a more detailed comparative analysis. Here are some key aspects to consider when deciding between these two methods for your metal fabrication needs:

Durability and Longevity

- Powder Coating: Renowned for its exceptional durability, powder coating creates a hard finish that is far more resistant to chipping, scratching, and fading compared to other finishes. It’s particularly well-suited for items exposed to extreme conditions or heavy usage, providing long-lasting protection.

- Paint: While paint can offer a protective layer, it generally lacks the robustness of powder coating. Painted surfaces are more vulnerable to damage from environmental factors, mechanical wear, and can deteriorate faster, necessitating more frequent maintenance and recoating.

Environmental Impact

- Powder Coating: Stands out as the more eco-friendly option. For example, powder coating produces negligible amounts of VOCs, making it safer for the environment and workers. Additionally, its overspray can be collected and reused, minimizing waste.

- Paint: Traditional liquid paints release higher levels of VOCs during application and drying, contributing to environmental and health concerns. The process is also less efficient in terms of solvent and material usage, leading to more waste and potential pollution.

Aesthetic Flexibility

- Powder Coating: Offers a commendable variety of colors and finishes, including matte, glossy, and textured options. While it provides aesthetic versatility, matching specific colors can be more challenging due to the nature of the powder mixing process.

- Paint: Excels in providing a more extensive color palette and allows for easier and more precise color matching. This flexibility makes paint ideal for projects requiring specific shades, intricate designs, or frequent color changes.

Cost Considerations

- Powder Coating: Tends to be more cost-effective in the long term. Its durability means less frequent reapplication, saving on labor and material costs over time. The initial investment in equipment and setup can be higher, but the reduced maintenance offsets these costs.

- Paint: Generally has a lower upfront cost, making it an attractive option for smaller projects or those with budget constraints. However, its susceptibility to wear and environmental damage can lead to increased costs over time due to the need for regular maintenance and recoating.

5. 4 Tips for Choosing the Right Option for Your Business

Following the comparative analysis of powder coating and paint, it’s clear that both options have distinct benefits and limitations. To help businesses make a well-informed decision, here are some focused tips on selecting the appropriate metal finishing technique:

#1 Assess Your Durability Requirements

For businesses that require high-durability finishes due to exposure to harsh environments or the need for long-lasting products, powder coating is often the better choice. For instance, its resistance to wear, and chemicals makes it ideal for heavy-duty applications. On the other hand, if aesthetic appeal and the flexibility to update appearances are more critical, paint can be an appropriate option.

#2 Consider Environmental and Health Impacts

Businesses prioritizing environmental sustainability should lean towards powder coating, which offers lower volatile organic compound (VOC) emissions. This choice aligns with green initiatives and can enhance a company’s environmental profile. For paint options, selecting high-quality, low-VOC paints becomes important to meet regulatory compliance and minimize health risks.

#3 Evaluate Color and Finish Requirements

When specific color matching is vital for branding or detailed design work, paint provides a wider range of colors and easier customization. Conversely, powder coating is preferred for specialized finishes, including textures and unique effects. While it may offer fewer options in precise color matching, the quality and durability of the finishes are often superior.

This table compares paint and powder coating in terms of color and finish options, helping to understand their applications based on specific requirements.

| Criteria | Paint | Powder Coating |

| Color Matching | Offers a wider range for precise matching | Limited options in precise color matching |

| Customization Possibilities | Easier to customize for specific designs | Offers specialized finishes and textures |

| Quality of Finish | Good for detailed work | Superior in terms of durability |

| Application Variety | Ideal for branding and detailed designs | Preferred for industrial and outdoor use |

| Environmental Impact | Higher VOC emissions | More environmentally friendly |

#4 Analyze Cost-Efficiency and Budget

Powder coating generally emerges as the more economical choice in the long run. Its durability reduces the need for frequent reapplications, thereby saving money over time. For businesses facing immediate budget constraints, paint might be a more viable option due to its lower upfront costs. It’s important to factor in the potential for higher long-term maintenance and recoating expenses associated with paint finishes.

Conclusion

The choice between powder coating and paint is more than a technical decision—it’s a strategic business move. Powder coating is renowned for its robustness, whereas paint offers versatility in color and is more economical for smaller projects.

For businesses in the metal fabrication sector, Zemetal is dedicated to providing exceptional metal fabrication services Contact us today to explore how we can help elevate your metal fabrication projects.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.