Are you curious about the impact that Powder Coating Colors can have on the functionality and style of your metal fabrication projects?

As experts in metal fabrication, we understand the significance of aesthetics and longevity in your projects. Trust us to guide you through the vibrant world of Powder Coating Colors.

Powder Coating Colors are not just about looks; they’re a statement of quality and commitment. These coatings blend beauty with durability, making your metal products both striking and long-lasting.

In this article, we’ll explore how Powder Coating Colors can elevate your business, from enhancing visual appeal to improving resistance against wear and tear.

Stay tuned to discover how the right color choice can make all the difference.

1. Basics of Powder Coating Colors

Powder coating, a dry finishing process favored in the metal fabrication industry, is gaining traction, as seen in the market’s growth projections. According to IndustryArc, the Powder Coatings Market will hit US$18.2 billion by 2027, growing at a 6.1% CAGR. This method, distinct from traditional liquid paint, involves applying a dry powder, usually via an electrostatic process, and then curing it under heat.

Not only does it offer a superior finish, but it’s also environmentally friendly, emitting fewer volatile organic compounds (VOCs). I’m particularly impressed with how this method balances eco-consciousness with top-notch quality. The powder, a blend of finely ground pigment and resin, ensures a dense, uniform finish, essential for both the aesthetic and fu`nctional aspects of metal fabrication.

2. Benefits of Using Powder Coating Colors

After exploring the basics of powder coating colors, it’s important to understand the significant advantages they offer. Below are the benefits of using powder coating colors:

Custom Color Matching

Tailor colors to specific client preferences or corporate branding, ensuring a unique and personalized look for each project. This feature is particularly beneficial for businesses looking to establish a strong brand identity through their products. Furthermore, custom color matching allows for greater flexibility in design, enabling creativity and innovation.

Texture Varieties

Choose from smooth, matte, gloss, or textured finishes, allowing for a diverse range of tactile experiences and visual effects. These textures not only add to the aesthetic value but also can influence the functionality of the coated item. For instance, a textured finish can provide additional grip on certain surfaces, making it a practical choice for specific applications.

Durability and Consistency

Powder coatings provide a consistent and durable finish, ensuring that products maintain their aesthetic appeal over time. This durability is especially important in industries where products are exposed to harsh conditions. Consistent quality across batches also means that customers can rely on the same high standards for all their orders.

Environmentally Friendly Options

With lower VOC emissions, powder coatings are an eco-friendlier choice, contributing to sustainability goals. This aspect is increasingly important as businesses and consumers alike are becoming more environmentally conscious. Additionally, the reduced environmental impact of powder coatings can be a significant selling point for businesses marketing to eco-aware customers.

3. Color Selection and Design Implications

Following the benefits of using powder coating colors, it’s essential to know the implications of color selection and its impact on design. Consider these crucial aspects in color selection and their impact on your product:

Reflecting Brand Identity

The color chosen should mirror the brand’s values and message. It’s a powerful tool for creating a visual connection with the brand, making it critical to select colors that embody the brand’s essence. Consistency in color across products can strengthen brand recognition and customer loyalty. Zemetal prioritizes aligning color choices with these principles to enhance the brand’s distinctiveness and appeal to our customers.

Target Audience Preferences

Colors should be chosen with the target demographic in mind. Different age groups, cultures, and markets have varying preferences. By understanding these preferences, businesses can select colors that resonate with their target audience, increasing the product’s appeal and market success. Adapting to the cultural significance of colors in different regions can enhance global marketability and relevance.

Psychological Impact of Colors

Colors evoke certain emotions and associations. Choosing the right color can create the desired emotional response in customers, whether it’s trust, excitement, or calm. This psychological aspect should be a key consideration in design, as it can significantly affect customer perception and interaction with the product. Strategic use of color psychology can uniquely distinguish a product in the market.

Environmental Suitability

The intended use environment of the product should guide color selection. For outdoor applications, colors that withstand UV rays and weather conditions are ideal. In contrast, for indoor products, one might choose colors that complement interior design trends and lighting conditions. Considering how lighting affects color perception is key to ensuring the product looks optimal in its intended environment.

Keeping Up with Trends

Staying informed about current color trends is vital. While it’s important to choose colors that are trendy and appealing, it’s equally crucial to consider their longevity and how they might age over time. Personally, I’ve found that blending current trends with timeless classics can create a lasting impact on a product’s appeal. Balancing trendiness with classic appeal ensures the product remains relevant and attractive in the long run.

4. Application Techniques for Vibrant and Consistent Colors

Building on the color selection and design implications, mastering application techniques is key to achieving vibrant and consistent colors in powder coating. Below are some essential techniques for optimal color application:

Proper Surface Preparation

The key to vibrant colors starts with surface preparation. Ensuring the metal is clean, free of oil, and properly sanded or blasted can significantly affect the final color appearance. This step is crucial for adhesion and color consistency. In my experience, meticulous surface preparation has been the cornerstone of achieving flawless and lasting color results.

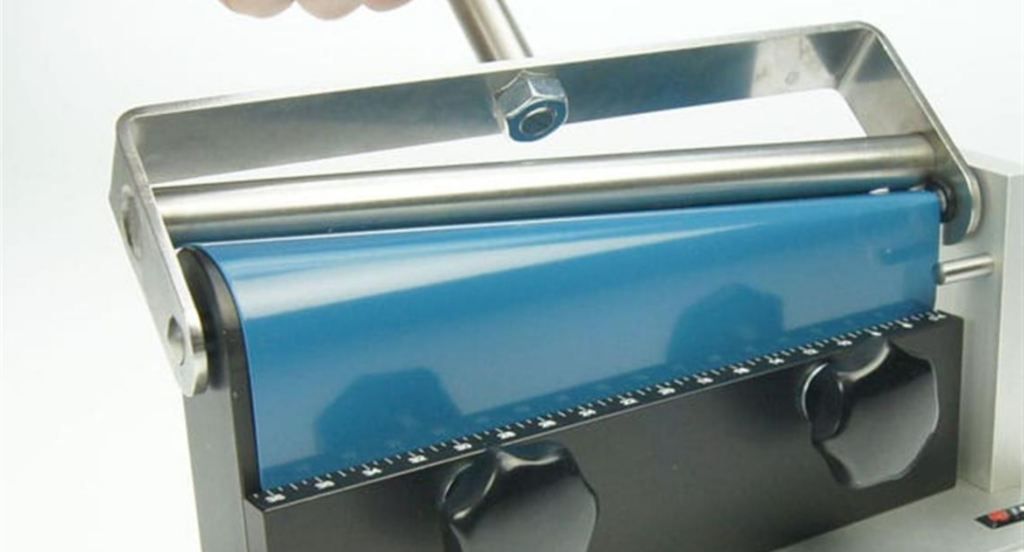

Electrostatic Spray

This is the most common method for applying powder coating. It involves electrically charging the powder particles so they adhere to the grounded metal surface. This technique ensures even coverage and vibrant colors. Additionally, it allows for more efficient use of powder, as excess material can be collected and reused, reducing waste.

Fluidized Bed Application

Ideal for thicker coatings, this method involves dipping the heated metal part into a fluidized bed of powder. It provides a thicker, more uniform coating, perfect for parts requiring enhanced durability. For instance, this technique is often used for heavy-duty machinery parts or outdoor furniture, where extra protection and robustness are crucial.

Curing Process Control

Proper curing is vital for color vibrancy and durability. The metal must be heated to the right temperature for the correct amount of time. This ensures the powder melts and cross-links properly, resulting in a strong, vibrant finish. Accurate control of the curing process also helps prevent defects such as bubbling or discoloration.

Quality Control Checks

Consistent quality control throughout the application process ensures vibrant and uniform colors. Regular checks help identify any issues early, allowing for adjustments to maintain color consistency. These checks are not only crucial for color quality but also for ensuring the overall durability and finish of the coated product. Zemetal prioritizes these controls to guarantee excellence in every project they undertake.

5. Trends and Popular Color Choices in Powder Coating

Following the discussion on application techniques, it’s important to examine the current trends and popular color choices in powder coating. Below are the trending hues and preferences shaping the industry today:

Sustainability-Inspired Colors

Eco-friendly themes are influencing color choices, with natural and earthy tones becoming increasingly popular. These colors not only reflect environmental consciousness but also resonate with customers who prefer sustainable and eco-friendly products. Shades like forest green, earthy brown, and sky blue are examples of this trend.

Metallic and Textured Finishes

There’s a growing preference for metallic and textured finishes in powder coatings. These finishes add a touch of luxury and sophistication, making them ideal for high-end products. Metallic shades like silver, gold, and bronze, along with textures that mimic natural materials, are in demand. Moreover, these finishes offer a modern twist to classic designs, appealing to a market looking for innovation in traditional products.

This table highlights the key aspects of metallic and textured finishes in powder coatings, which are increasingly popular for their luxurious and sophisticated appearance. They are especially sought after in high-end products for their ability to provide a modern twist to classic designs.

| Aspect | Description | Market Appeal |

| Metallic Shades | Shades like silver, gold, and bronze offer a shiny, reflective quality. | These shades attract customers seeking a blend of classic elegance and modern aesthetics. |

| Textured Finishes | Finishes that mimic natural materials like wood or stone. | Textured coatings are popular for their ability to add depth and a natural feel to products. |

| Application in Traditional Products | Using these finishes in classic product designs. | This approach meets the demand for innovation in traditional items, appealing to a market that values both heritage and modernity. |

Bold and Vibrant Hues

Bold and vibrant colors are making a statement in the powder coating industry. These colors are perfect for products that aim to stand out and attract attention. Bright shades like neon green, electric blue, and fiery red are part of this trend. They cater especially to a younger demographic or sectors that favor high-energy designs and striking visual impact.

Pastel and Soft Tones

On the other end of the spectrum, pastel and soft tones are gaining popularity for their subtle and soothing effect. These colors are ideal for products that aim for a gentle, calming aesthetic. Soft pinks, light blues, and pale yellows are popular choices in this category. These tones work well in environments that seek to evoke tranquility and understated elegance, such as healthcare and wellness centers.

Classic and Timeless Colors

Despite the fluctuation in trends, classic colors like black, white, and gray remain consistently popular. These colors offer a timeless appeal and versatility, making them suitable for a wide range of products and applications. In my view, the enduring popularity of these classics underscores their ability to seamlessly adapt to various styles and settings.

6. Maintenance and Care of Powder-Coated Surfaces

Moving on from trends and popular color choices, let’s focus on the essential aspects of maintenance and care for powder-coated surfaces. Here are essential maintenance and care tips for powder-coated surfaces:

Routine Cleaning

Regular cleaning is crucial for maintaining the aesthetic of powder-coated surfaces. Use mild soap and water for cleaning, avoiding harsh chemicals that can damage the coating. Gentle wiping rather than abrasive scrubbing is recommended to preserve the finish. Additionally, regular cleaning helps in identifying any minor issues before they escalate, ensuring the longevity of the coating.

Inspecting and Touching Up

Periodic inspections can help catch any chips, scratches, or wear before they worsen. For minor damage, touch-up paints specifically designed for powder-coated surfaces can be used to maintain the coating’s integrity and appearance. From my experience, timely touch-ups not only keep surfaces looking new but also extend their lifespan significantly.

Preventing Chemical Damage

Be mindful of exposure to harsh chemicals, including industrial solvents and acidic cleaners. These substances can corrode or discolor the powder coating. Always opt for gentle, pH-neutral cleaning agents for safe maintenance. It’s also advisable to rinse the surface immediately if it comes into contact with any potentially harmful substances.

Professional Assessment for Major Repairs

In cases of significant damage or wear, it’s advisable to consult with a professional for proper repair or re-coating. This ensures that the integrity of the powder coating is restored effectively, maintaining its protective and aesthetic qualities. Professional assessment is especially important for complex or large-scale projects, where expert knowledge can make a significant difference in the outcome.

7. 4 Tips for Choosing the Right Colors for Your Business

Following the insights on maintenance and care, it’s important to focus on selecting the most suitable colors for your business. Here are some of the key tips for selecting the best colors for your business:

#1 Understand Your Brand Personality

Choose colors that reflect your brand’s character and values. If your brand is vibrant and energetic, opt for bright and bold colors. For a more sophisticated and professional look, consider muted or neutral tones. This alignment helps reinforce your brand identity in the eyes of your customers. Remember, the colors you choose will often be the first impression of your brand, so make it count.

#2 Research Your Target Market

Different demographics and customer segments have varying color preferences. Conduct market research to understand what appeals to your target audience. This can involve surveys, focus groups, or studying industry trends to get a sense of which colors resonate most with your customers. Tailoring your color choices to your audience can significantly increase the attractiveness and relevance of your products

#3 Consider Industry Trends

Stay informed about the latest color trends in your industry. While it’s important to maintain a unique identity, aligning with industry trends can make your products more appealing to a wider audience. However, ensure that these trends align with your brand values and don’t just follow them for the sake of being trendy. Balancing trendiness with brand authenticity can help you stay relevant without losing your unique identity.

#4 Test and Get Feedback

Before finalizing a color scheme, test it with a small group of your target market. Getting feedback can help you refine your choices and ensure that they have the desired impact. This could involve creating prototypes or digital mockups to gauge reactions. This direct customer feedback has been invaluable in fine-tuning color choices to better meet market expectations and preferences.

Conclusion

In conclusion, this guide has provided valuable insights and tips to help businesses thrive in today’s competitive market. By following the strategies outlined here, you can improve your operations, boost efficiency, and achieve long-term success.

If you’re looking for expert guidance and solutions to enhance your business further, consider partnering with Zemetal. Feel free to reach out to us for more information; we’re here to help! Contact us today.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.