Navigating Industry Trends

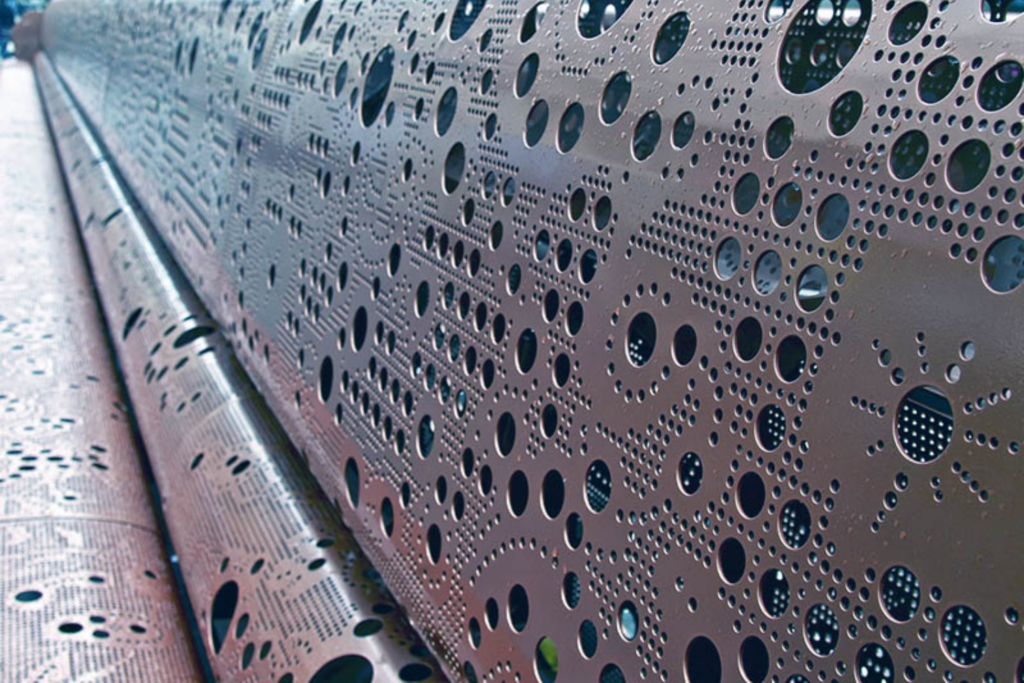

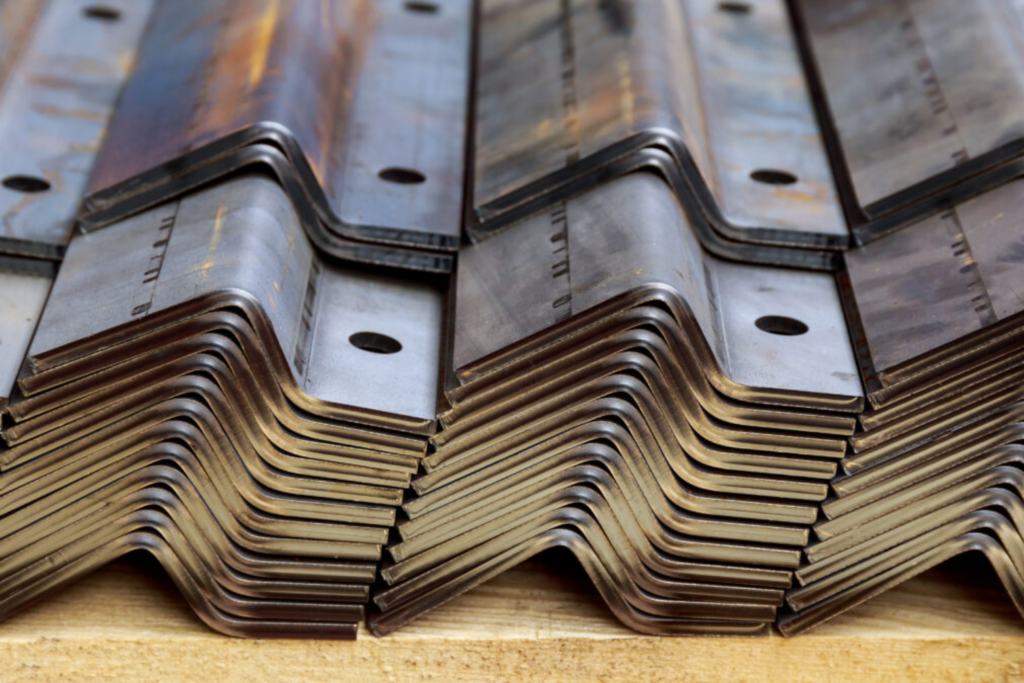

Explore our industry-related pages for a comprehensive look at the current trends and future directions in sheet metal fabrication. Each page offers detailed insights into how these evolving trends impact various sectors, equipping you with knowledge to stay ahead in the dynamic world of metal processing.

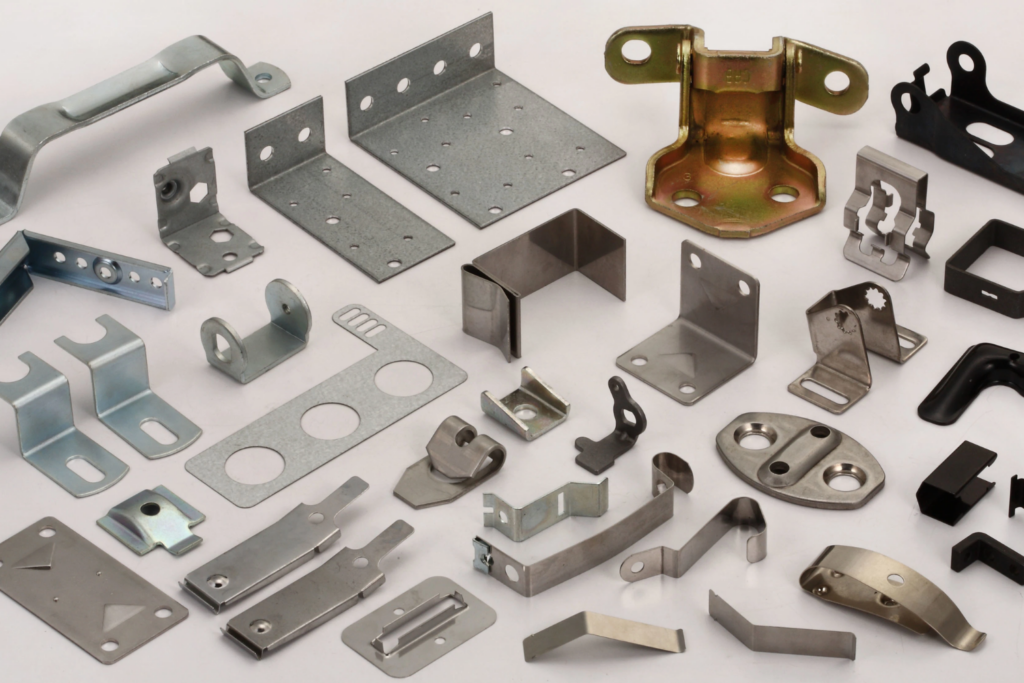

Exploring the Multifaceted Applications of Sheet Metal Fabrication

- Automotive: Essential for the structural elements of cars, buses, and recreational vehicles.

- Electronics & Hardware: Provides durable enclosures and heat sinks for devices.

- Appliances: Forms the robust, reliable frames and components within consumer appliances.

- Architecture & Construction: Offers versatile, strong materials for construction needs.

- Defense: Delivers high-grade metal parts critical for defense equipment.

- Medical Equipment: Ensures sterile, precision-crafted components for medical devices.

- Agriculture: Creates sturdy, weather-resistant components for agricultural machinery.

Meet the Experts Behind Zemetal

01

Media Team

For content collaborations or to join our blog contributors, please contact [email protected]. We welcome fresh perspectives and are committed to enriching our metal sheet fabrication industry platform with diverse insights. Let’s innovate together.

02

Quality Assurance Team

In our Quality Assurance Team, we meticulously ensure a 99.8% precision rate in every project, embodying our dedication to superior quality and a zero-error approach in metal sheet fabrication.

03

Research & Development Team

Leading with over 30 innovative techniques, our R&D Team enhances fabrication efficiency and precision by 25%, constantly redefining creativity and scientific accuracy in metal sheet fabrication.

04

Engineering & Design Team

Our Engineering & Design Team, with over 500 bespoke projects, expertly fuses creative design with engineering precision, ensuring each fabrication project excels in functionality and aesthetics.

Empowering Goals With Us

At Zemetal, our partnership with a pioneering electric vehicle firm is a testament to our dedication to precision, sustainability, and efficiency. Utilizing our cutting-edge fabrication skills and eco-friendly practices, we played a pivotal role in addressing critical challenges faced by Mr. Frazier's company. This collaboration resulted in a staggering 30% enhancement in vehicle performance, marking a significant milestone in our journey towards innovative excellence.

Our collaboration with Mr. Virden's HVAC company is a shining example of Zemetal's commitment to delivering bespoke metal fabrication solutions that are both innovative and efficient. By embracing and solving unique architectural challenges, we not only improved the functionality of their HVAC systems but also seamlessly integrated them into the desired aesthetics. This strategic partnership led to substantial growth for our client, showcasing the transformative impact of our tailored solutions.

Working with Mr. Park and his team at the automotive company highlighted Zemetal's unwavering commitment to precision, innovation, and efficiency. By confronting their complex challenges with our advanced manufacturing techniques, we didn't just meet their high standards; we played a crucial role in significantly boosting their vehicle performance. This collaboration underscores our dedication to pushing the boundaries of what's possible in automotive excellence.

Previous

Next

Meet Our Best Sheet Metal Fabrication Laser Cutting Blanking Stamping Weilding Bending Services

Connect with Us

Zemetal is committed to ensuring your privacy and promises prompt, secure responses to all your inquiries.