Has anyone pondered the importance of stainless steel sheet metal fabrication in today’s industries? It’s not just prevalent; it’s fundamental for its strength and adaptability.

With years of hands-on experience and a deep understanding of the metal industry, I’m here to guide you through the details of stainless steel sheet metal fabrication.

Stainless steel sheet metal fabrication stands at the forefront of manufacturing, offering a remarkable blend of durability and precision. Its ability to withstand harsh environments and retain shine makes it essential for numerous applications.

In this guide, you’ll discover the techniques, types and applications that make stainless steel sheet metal fabrication a preferred choice for businesses.

Read on to unlock the potential of stainless steel in your projects.

1. Overview of Stainless Steel Sheet Metal Fabrication

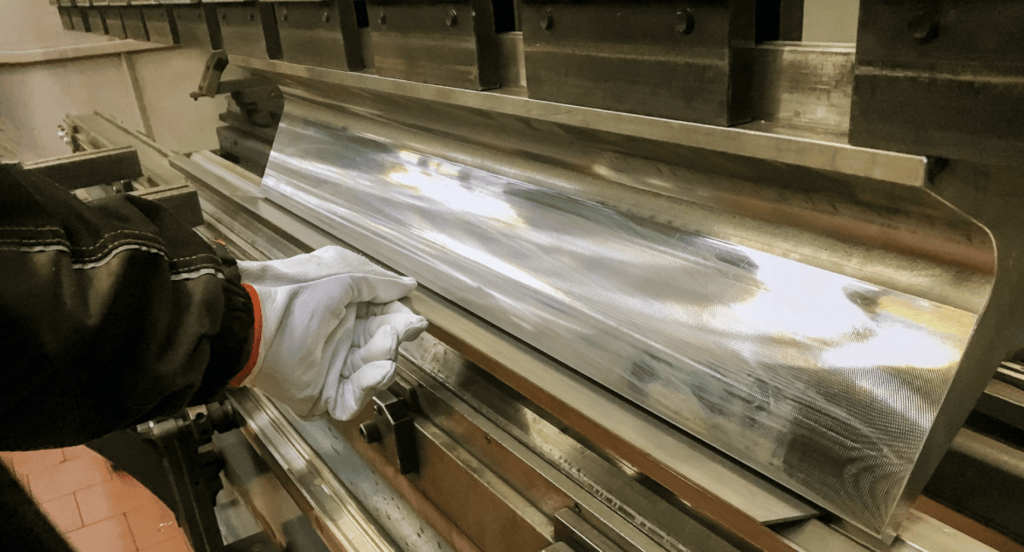

Stainless steel sheet metal fabrication is a meticulous process, transforming flat sheets into items of varied shapes and sizes. This method is highly regarded for producing products that are as durable as they are elegant. From raw material to finished product, the journey involves cutting, shaping, and assembling, ensuring each piece precisely meets the demands of industries like aerospace and construction.

The precision in this art is remarkable, turning simple sheets into critical components for daily life and advanced technology. According to Fortune Business Insights, the global stainless steel sheet market is expected to reach $167.48 billion by 2030. This growth highlights stainless steel’s growing importance, ensuring its key role in producing dependable and efficient products.

2. Types of Stainless Steel Used in Fabrication

After exploring the fascinating world of stainless steel sheet metal fabrication and its precision, it’s time to delve into the types of stainless steel that bring these projects to life. Here are some of the most commonly used varieties:

Austenitic Stainless Steel

Austenitic stainless steel is highly popular due to its superior corrosion resistance and excellent formability. This type contains higher levels of chromium and nickel, making it an ideal choice for a wide range of environments. It’s fascinating to see how this type reshapes without losing strength, often used in kitchen equipment and architectural structures.

Ferritic Stainless Steel

Ferritic stainless steel is known for its good corrosion resistance and magnetic properties. With lower carbon and nickel content, it’s more cost-effective while still offering decent durability and performance. This type is often found in automotive parts and appliances, showcasing its versatility in everyday applications.

Martensitic Stainless Steel

Martensitic stainless steel is recognized for its high strength and moderate corrosion resistance. It’s the go-to for fabrication that demands both durability and a bit of flexibility. It includes surgical instruments and cutlery, where precision and longevity are key. The ability to harden through heat treatment makes it adaptable to various needs, ensuring a balance between toughness and workability.

3. Modern Techniques in Sheet Metal Fabrication

As the industry evolves, so do the techniques used in stainless steel sheet metal fabrication. Each method brings its unique advantages and applications, ensuring that businesses can find the perfect fit for their needs. Let’s explore some of the most advanced and efficient techniques currently in use:

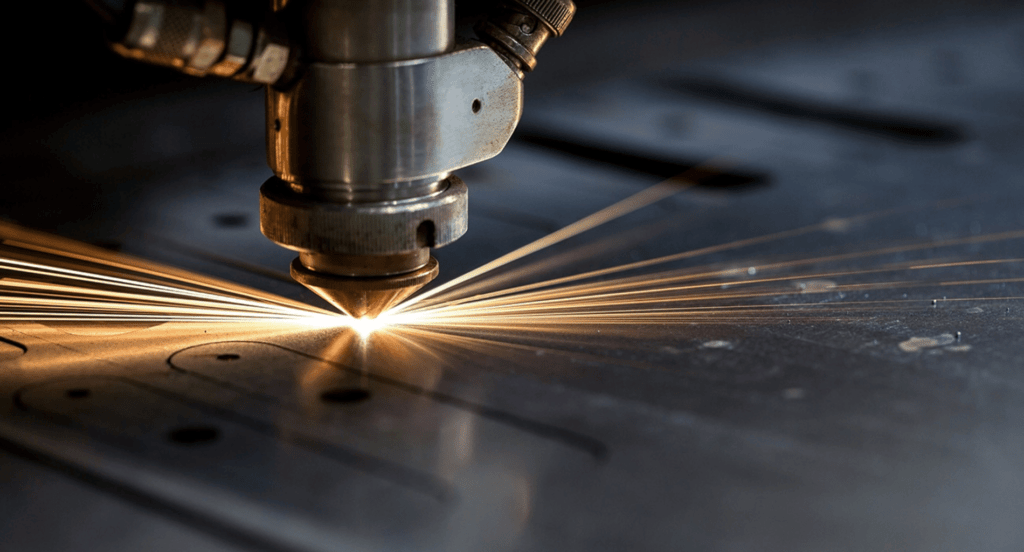

Laser Cutting

Laser cutting stands out for its precision and speed. By focusing a high-powered laser beam onto the material, intricate cuts and shapes are achieved with immaculate edges and minimal waste. The accuracy it provides is truly a game-changer, making it ideal for detailed and complex designs, particularly in electronics and automotive sectors.

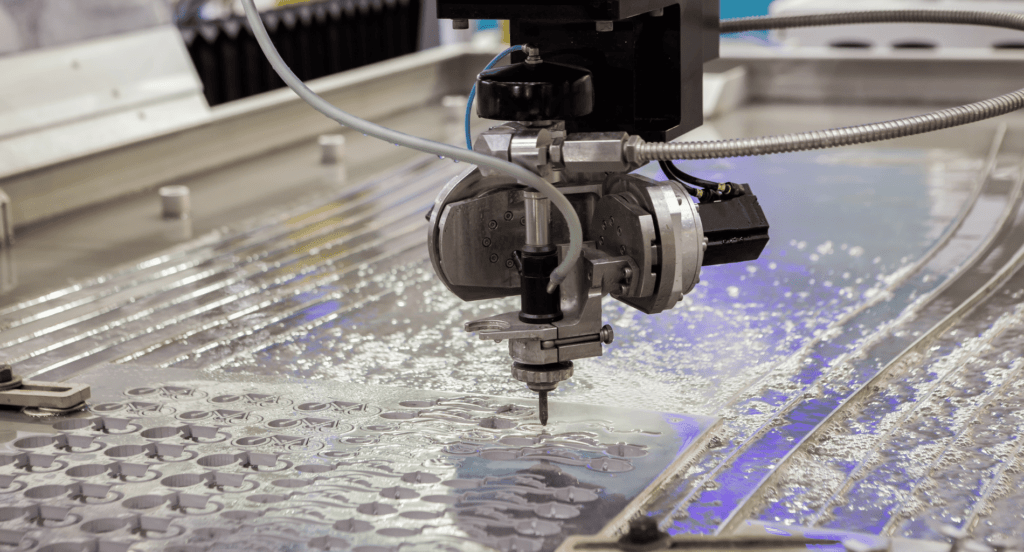

Water Jet Cutting

Water jet cutting is a versatile technique that uses a high-pressure stream of water, often mixed with an abrasive substance, to cut through materials. It’s celebrated for its ability to cut without introducing heat, preserving the properties of the metal. Zemetal utilizes this technique for projects requiring meticulous attention to detail and a clean cut, ensuring the integrity of stainless steel.

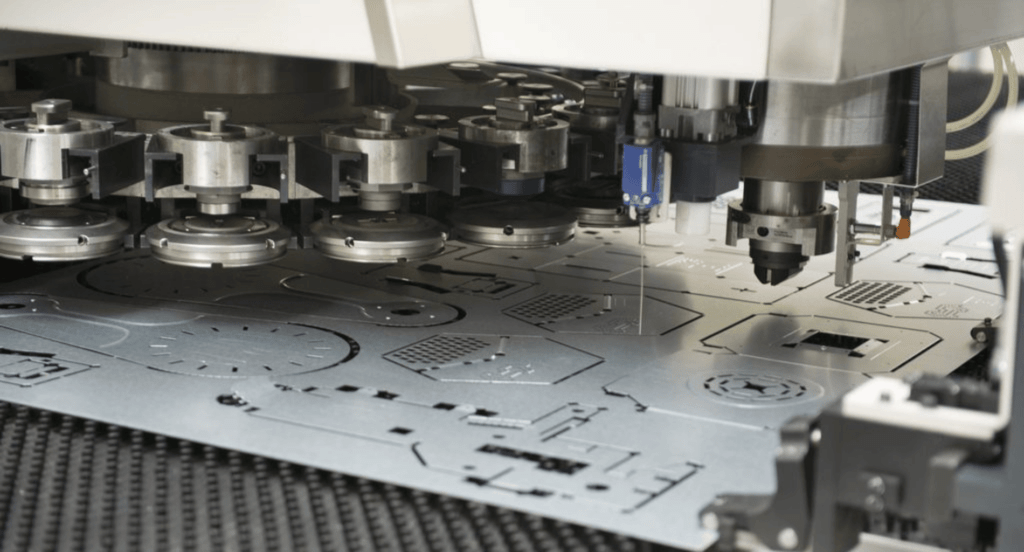

CNC Punching

CNC punching is a cost-effective and efficient process for creating holes and shapes in sheet metal. Controlled by computer programming, it ensures uniformity and precision across every piece. This technique is indispensable for large-scale production runs where consistency and speed are paramount. The ability to rapidly produce uniform components is nothing short of impressive, making it a staple in the industry.

4. Common Applications of Stainless Steel Fabrication

The adaptability and resilience of stainless steel have led to its widespread use across diverse sectors. Its unique properties provide solutions that are both practical and innovative. Let’s explore some specific industries that benefit significantly from stainless steel fabrication:

Construction and Architecture

In construction and architecture, stainless steel is used for its sleek appearance and structural integrity. It’s a popular choice for facades, roofing, and support beams, offering both aesthetic and functional benefits. Its ability to endure the elements and retain its shine makes it a favorite for innovative and lasting architectural designs.

Food and Beverage Industry

In the food and beverage industry, stainless steel is the material of choice for equipment, storage tanks, and utensils due to its resistance to corrosion and easy cleaning. The non-reactive nature of stainless steel ensures that it doesn’t impart any flavors or contaminants, maintaining the purity and safety of consumables. This industry’s reliance on stainless steel helps maintain high hygiene standards and product quality.

Medical Industry

Stainless steel is critical in the medical field for instruments, implants, and equipment. Its hygienic properties, coupled with strength and precision, make it indispensable. The material is used in everything from surgical tools to hospital trolleys, ensuring safety and reliability where it matters most. The trust placed in stainless steel within the medical field underscores its unparalleled quality and performance.

5. Cost Considerations in Stainless Steel Fabrication

While stainless steel fabrication is crucial across industries for its durability and versatility, understanding the cost implications is vital for effective budgeting and decision-making. Here, we’ll break down some of the key factors that influence the cost of stainless steel fabrication:

Material Costs

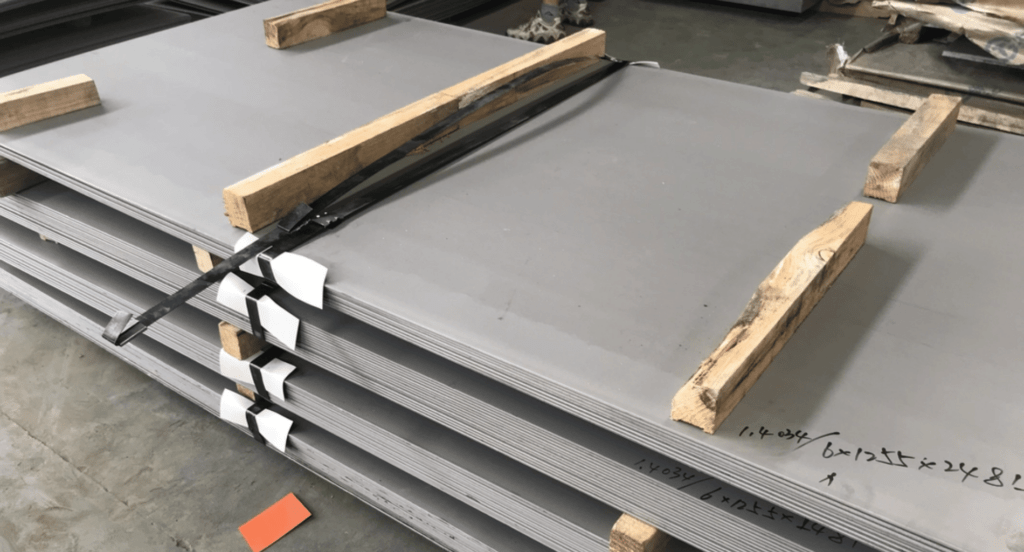

The price of stainless steel varies widely based on grade, market conditions, and quantity. For example, a sheet of 304-grade stainless steel, commonly used for its good corrosion resistance and formability, might cost around $1080 to $1270 per ton. Specialized grades like 316, with enhanced properties, can cost up to 30% more. Bulk buying typically offers discounts, yet the initial outlay remains a substantial project cost.

Labor Costs

Skilled labor is essential for quality stainless steel fabrication, and the cost of hiring experienced professionals can be considerable. For example, specialized welders or CNC machine operators typically command higher wages due to their expertise. A project requiring 10 hours of work at an average rate of $20-25 per hour would result in $200-250 just in labor costs.

6. Safety Practices in Stainless Steel Fabrication

Safety is paramount in the world of stainless steel fabrication, where the combination of heavy materials and high-powered machinery presents a significant risk. Here, we’ll discuss essential safety measures that are crucial for protecting workers and ensuring a smooth operation:

Personal Protective Equipment (PPE)

Wearing the right Personal Protective Equipment is fundamental in any fabrication environment. This includes items like safety goggles, gloves, and ear protection to guard against common hazards such as flying sparks, sharp edges, and excessive noise. Ensuring each team member is properly equipped is a responsibility taken seriously at Zemetal, recognizing that safety is the foundation of quality craftsmanship in every project.

Hazard Communication and Training

Effective communication and regular training are vital in minimizing workplace hazards. This involves clear instruction on handling equipment and materials, as well as educating staff on potential risks. Regular safety drills and updates on best practices keep the workforce alert and prepared, to ensure everyone’s safety and well-being.

Machine Guarding and Maintenance

Proper guarding of machinery and consistent maintenance are essential for accident prevention. This involves implementing safety shields on cutting and welding equipment and ensuring all machinery undergoes routine checks and servicing. A dedication to equipment maintenance not only safeguards the workforce but also ensures that each project adheres to the highest standards of safety and quality.

7. Troubleshooting Common Fabrication Challenges

In stainless steel fabrication, encountering challenges is part of the process. Understanding how to effectively address these issues is key to maintaining productivity and ensuring the quality of the final product. Let’s explore some common hurdles and the strategies to overcome them:

Warping and Distortion

Warping and distortion can occur during welding or heat treating due to uneven heat distribution. To mitigate this, it’s crucial to use proper clamping techniques and ensure even heating and cooling. Pre-planning the sequence of welding can also reduce the stress and distortion on the metal. Effective heat management is crucial, greatly affecting the finished product’s structure and appearance.

Material Reactivity and Corrosion

Stainless steel is chosen for its corrosion resistance, but certain environments or treatments can compromise this quality. Ensuring that the material is properly stored and handled to prevent contamination with corrosive substances is critical. Additionally, choosing the right grade of stainless steel for the specific environment it will be used in can prevent premature degradation.

Adhering to Specifications

Meeting the exact specifications of a project can be challenging, especially when working with complex designs or tight tolerances. It’s important to have a detailed and clear understanding of the project requirements from the start. Collaborating with designers and conducting thorough quality checks throughout fabrication ensures the final product meets all specifications and standards.

Below is a table highlighting key steps in ensuring a project meets its exact specifications, focusing on collaboration and quality assurance:

| Step | Description |

| Define Project Scope | Establish clear, detailed project requirements and objectives. |

| Collaborate with Designers | Work closely with designers to understand and integrate complex designs or tight tolerances. |

| Implement Quality Checks | Conduct quality checks at every stage of fabrication to identify and correct deviations. |

| Use Precise Tools and Techniques | Employ tools and techniques that enhance accuracy and adherence to specifications. |

| Continuous Communication | Maintain open lines of communication among all stakeholders for adjustments and feedback. |

8. Innovations and Future Trends in Stainless Steel Fabrication

Overcoming fabrication challenges is just the beginning. The industry is constantly evolving with new innovations and trends that promise to redefine the standards of stainless steel fabrication. Here’s a glimpse into the future, showcasing what’s next for this dynamic field;

3D Printing and Additive Manufacturing

3D printing and additive manufacturing are set to transform stainless steel fabrication. This technology allows for complex shapes and structures to be created with less waste and in shorter timeframes. The ability to print components layer by layer offers unparalleled design freedom and efficiency. The potential for customization and rapid prototyping is truly exciting, paving the way for new applications and innovations.

Smart Manufacturing and Internet of Things (IoT)

The integration of smart manufacturing and the Internet of Things (IoT) in the fabrication process is a game-changer. Real-time monitoring and data analysis can optimize operations, predict maintenance needs, and increase overall productivity. Sensors and connected devices can ensure that each step of the fabrication process is as efficient and precise as possible, leading to higher quality products and reduced costs.

Advanced Material Composites

Advanced material composites are poised to significantly reshape stainless steel fabrication. By combining stainless steel with materials like carbon fiber or advanced polymers, the resulting products can offer improved strength, reduced weight, and enhanced resistance to environmental factors. This blend of materials opens up new possibilities, allowing for more innovative and efficient designs in various applications.

Conclusion

This guide has journeyed through the detailed world of stainless steel sheet metal fabrication, providing insights and understanding to navigate its complexities with confidence. The knowledge shared here is designed to enhance decision-making and innovation in your projects.

Consider Zemetal for your next fabrication venture for unparalleled quality and service. For further information or to discuss your specific requirements, please don’t hesitate to contact us.

Dive Deeper Into Our Resources

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.