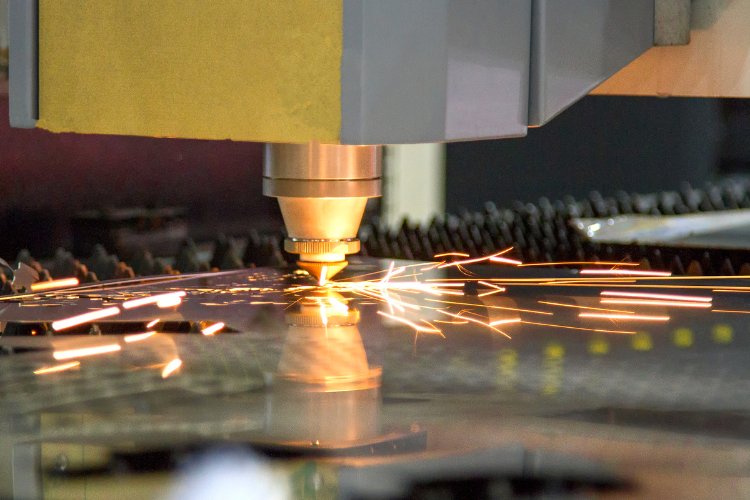

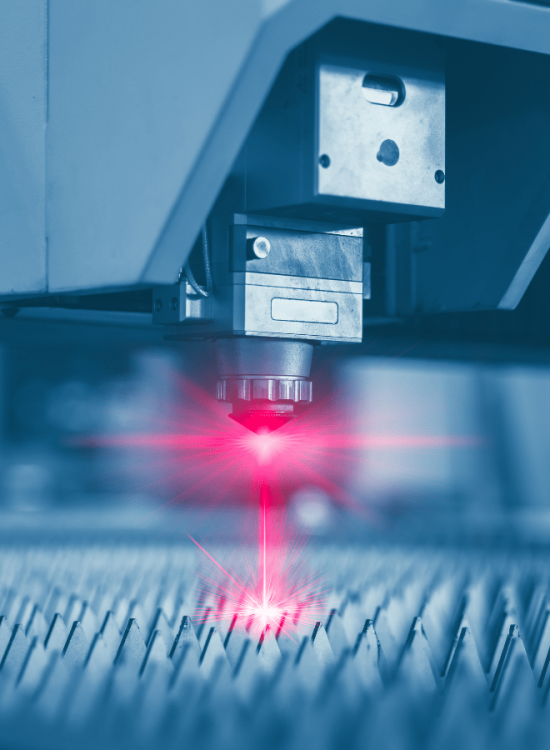

Laser Edging

Dive into our selection of top-tier metal services, where unparalleled quality meets innovative design. Each item in our range is a testament to our commitment to excellence in metal fabrication.

Explore Our Premium Metal Fabrication Range

Zemetal stands at the forefront of innovation in laser edging technology, offering unparalleled precision and quality in metal fabrication. Our team, equipped with state-of-the-art laser edging machines, excels in delivering custom solutions that meet the diverse needs of our clients. We specialize in crafting intricate designs and complex shapes, ensuring each product meets rigorous standards of excellence.

Our commitment to using advanced laser technology allows us to produce components with exceptional accuracy and speed, making us a trusted partner in various industries. We understand the importance of reliability and efficiency in today’s fast-paced market and are dedicated to providing services that not only meet but exceed expectations.

With our focus on continuous improvement and client satisfaction, we are your ideal choice for top-quality laser edging solutions.

Zemetal: Who We Are

Our Founding Journey

Established with a vision to revolutionize the sheet metal processing industry, our journey reflects a blend of innovation, precision, and dedication. From our humble beginnings, we’ve evolved into a leader in sheet metal processing and batch production. Our success is built on a commitment to quality and relentless technological advancement, setting new standards in the industry.

Inside Our Facility

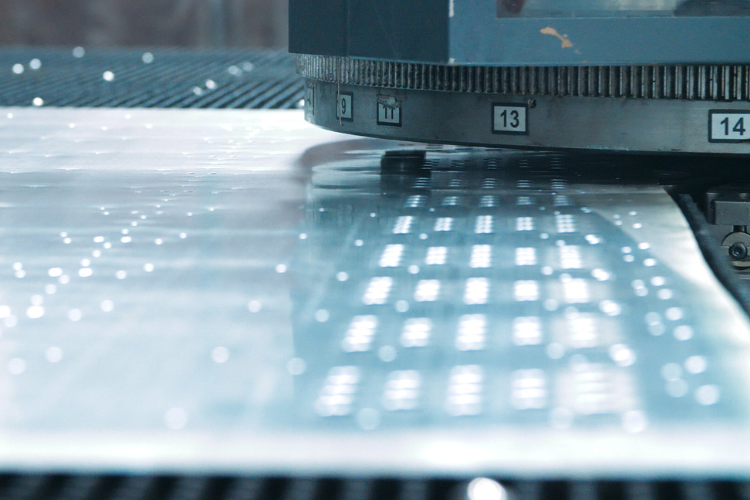

Step into our state-of-the-art factory, where advanced technology meets skilled craftsmanship. Optimally designed for efficiency, our facility is the heart of our sheet metal production. We handle intricate designs and large-scale outputs with precision, ensuring every product meets the highest quality benchmarks. Our factory is a testament to our capability to handle diverse, high-volume demands with precision.

Innovation & Development

At the core of our operation is a robust Research & Development wing, pushing the frontiers of sheet metal processing. Our R&D team, equipped with cutting-edge tools and driven by innovation, continually develops new methods to enhance efficiency and product quality. This relentless pursuit of improvement sets us apart and ensures we stay ahead in a rapidly evolving industry.

Certification Excellence

Our commitment to excellence is affirmed by our comprehensive range of industry certifications. Each certificate represents our adherence to stringent quality standards, environmental practices, and safety protocols. These certifications are a promise to our clients that every sheet metal product we deliver is crafted to perfection, adhering to the highest industry benchmarks. Trust and quality are the pillars of our service.

Meet the Experts Behind Zemetal

01

Media Team

For content collaborations or to join our blog contributors, please contact [email protected]. We welcome fresh perspectives and are committed to enriching our metal sheet fabrication industry platform with diverse insights. Let’s innovate together.

02

Quality Assurance Team

In our Quality Assurance Team, we meticulously ensure a 99.8% precision rate in every project, embodying our dedication to superior quality and a zero-error approach in metal sheet fabrication.

03

Research & Development Team

Leading with over 30 innovative techniques, our R&D Team enhances fabrication efficiency and precision by 25%, constantly redefining creativity and scientific accuracy in metal sheet fabrication.

04

Engineering & Design Team

Our Engineering & Design Team, with over 500 bespoke projects, expertly fuses creative design with engineering precision, ensuring each fabrication project excels in functionality and aesthetics.

Empowering Goals With Us

At Zemetal, our partnership with a pioneering electric vehicle firm is a testament to our dedication to precision, sustainability, and efficiency. Utilizing our cutting-edge fabrication skills and eco-friendly practices, we played a pivotal role in addressing critical challenges faced by Mr. Frazier's company. This collaboration resulted in a staggering 30% enhancement in vehicle performance, marking a significant milestone in our journey towards innovative excellence.

Our collaboration with Mr. Virden's HVAC company is a shining example of Zemetal's commitment to delivering bespoke metal fabrication solutions that are both innovative and efficient. By embracing and solving unique architectural challenges, we not only improved the functionality of their HVAC systems but also seamlessly integrated them into the desired aesthetics. This strategic partnership led to substantial growth for our client, showcasing the transformative impact of our tailored solutions.

Working with Mr. Park and his team at the automotive company highlighted Zemetal's unwavering commitment to precision, innovation, and efficiency. By confronting their complex challenges with our advanced manufacturing techniques, we didn't just meet their high standards; we played a crucial role in significantly boosting their vehicle performance. This collaboration underscores our dedication to pushing the boundaries of what's possible in automotive excellence.

Previous

Next

Your Manufacturing Demands, Our Expert Solutions

Comprehensive Fabrication Services

Offering a wide range of metal fabrication services, from cutting and bending to welding and assembling, tailored

to your specific requirements.

Advanced Technology & Equipment

Utilizing state-of-the-art machinery and technology to ensure high precision and quality in every project, meeting the

most demanding manufacturing standards.

Expert Team & Quality Assurance

Our skilled professionals are committed to delivering excellence. We adhere to strict quality control protocols to

ensure top-notch results.

Flexible Production Capacity

Whether you need a single prototype or large-scale production, our flexible manufacturing processes can adapt to your project’s scale and complexity.

Timely Delivery & Customer Support

We understand the importance of deadlines. Our efficient processes and dedicated support team ensure timely delivery and ongoing communication throughout your project.

Sustainable Practices & Material Options

Committed to environmental responsibility, we offer sustainable manufacturing practices and a variety of material choices, including eco-friendly and recycled options, to meet both

your project needs and environmental goals.

Applicable Materials for Laser Edging

Aluminum

Aluminum stands out for its lightweight yet strong properties, making it perfect for laser edging. It’s highly malleable, allowing for detailed and complex designs. Zemetal understands that aluminum’s ability to blend strength with weightlessness opens up a world of possibilities for innovative designs. Its excellent conductivity makes it a preferred choice for electronic components.

Copper

Copper is renowned for its thermal and electrical conductivity, making it a top pick for laser edging in electrical applications. Its malleability allows for precise and intricate designs, a key factor in electronic components. I have found that copper’s unique color and finish offer an unmatched aesthetic value, adding a touch of elegance to any project.

Brass

Brass is a composite material made from copper and zinc, known for its machinability and durability. It’s often chosen for laser edging when a balance of strength, corrosion resistance, and aesthetic appeal is needed. Brass is frequently used in decorative items, musical instruments, and fittings, benefiting from laser edging’s precision to create detailed patterns and shapes.

Mild Steel

Mild steel is a popular choice for laser edging due to its excellent machinability and cost-effectiveness. It’s well-suited for a wide range of applications, from industrial machinery to everyday consumer products. Mild steel can be easily welded and modified after laser edging, offering flexibility in design and use. Its versatility and affordability make it a staple in the laser edging industry, serving as the backbone for many standard projects.

Aluminum

Copper

Brass

Mild Steel

Features of Laser Edging

High Precision Cutting

Laser edging offers exceptionally high precision, allowing for intricate and complex designs that other methods cannot achieve. This feature is particularly crucial in industries where even the slightest deviation can affect the functionality of a component. The laser’s ability to cut with pinpoint accuracy ensures consistency across multiple productions.

Rapid Processing Speed

One of the standout features of laser edging is its rapid processing speed. Some have seen firsthand how this accelerates project timelines, enhancing productivity and efficiency. The speed of laser edging doesn’t compromise the quality of the cut, ensuring a high-quality finish in a fraction of the time required by traditional methods.

Minimal Material Distortion

The non-contact nature of laser edging results in minimal material distortion. In this aspect, it ensures the integrity of the material is maintained throughout the edging process. This is particularly important for delicate materials or applications where maintaining the material’s structural integrity is crucial. The focused laser beam produces a narrow cut with little heat affectation preserving the properties of the material.

Automated and Repeatable Process

Laser edging is highly automated, allowing for consistent and repeatable results. The use of advanced software and precise control systems ensures that every cut is uniform. This automation reduces the potential for human error and enhances the overall efficiency of the production process. It’s ideal for mass production where consistency is key.

Benefits of Laser Edging

Enhanced Design Flexibility

Laser edging allows for enhanced design flexibility, enabling designers and engineers to push the boundaries of creativity. Complex shapes and patterns that were once impossible to achieve are now feasible with laser technology. This flexibility opens up new possibilities in product design, allowing for the creation of unique and innovative products that stand out in the market.

Improved Product Quality

The precision and accuracy of laser edging result in improved product quality. At Zemetal, I have observed how this leads to fewer defects and a higher standard of finished products. The quality of the cut ensures that components fit together perfectly, which is crucial in precision engineering. This results in products that not only look better but also perform better and have a longer lifespan.

Cost-Effective Production

Laser edging is a cost-effective production method, especially for high-volume manufacturing. The reduction in material waste, combined with the speed and efficiency of the process, results in significant cost savings. The automation of laser edging reduces labor costs and the potential for errors, further enhancing its cost-effectiveness.

Low Maintenance Requirements

The laser edging equipment is known for its low maintenance requirements. This is a relief for some brands as it minimizes downtime and keeps production running smoothly. The durability of laser machines and the lack of direct contact with materials reduce wear and tear. This longevity and reliability of the equipment make it a valuable long-term investment for any manufacturing operation.

Applications of Laser Edging

Electronics and Semiconductors

In the electronics and semiconductor industries, laser edging is critical for producing small, detailed components. For example, it’s used in creating intricate circuit boards and connectors. This technology allows for precise cuts and shapes that are essential in the miniaturization of electronic devices. The accuracy and ability to work with a variety of materials make laser edging ideal for the evolving demands of this sector.

Architecture and Construction

Laser edging finds extensive use in architecture and construction for creating decorative elements and structural components. The precision and versatility of laser edging are perfect for crafting intricate designs in metal for aesthetic applications. It’s also used for cutting structural steel with high accuracy, essential for ensuring the safety and integrity of buildings and structures.

Consumer Goods

In the consumer goods industry, laser edging is used for creating a wide range of products, from kitchen appliances to jewelry. The ability to work with different materials and create intricate designs is particularly valuable in this sector. Products that require a high level of detail and precision, such as metal cutlery or decorative items, benefit from the accuracy and versatility of laser edging.

Automotive Industry

The automotive industry heavily relies on laser edging for manufacturing precision parts. My experience at Zemetal has shown that the level of accuracy required in automotive components is exceptionally high, and laser edging meets these stringent standards. This process is used for creating everything from intricate engine parts to aesthetic elements in car interiors.

Electronics and Semiconductors

Architecture and Construction

Consumer Goods

Automotive Industry

4 Things to Consider When Choosing Laser Edging Services

According to Volza’s Global Import data, Laser edging import shipments in World stood at 4.2K, imported by 552 World Importers from 472 Suppliers. Here are some important things to consider:

#1 Technological Advancements

The technology used by the laser edging service is a critical aspect to consider. Providers utilizing the latest technology and equipment can offer superior precision, efficiency, and capabilities. It can also maximize the laser processing results. Advanced technology can handle a wider range of materials and complex designs, providing you with more options for your projects.

#2 Quality Assurance and Standards

Quality assurance is paramount when choosing a laser edging service. It’s essential to select a provider that adheres to stringent quality standards and possesses the necessary certifications. This ensures that the services provided meet industry regulations and deliver products that are of consistently high quality. Inquire about their quality control processes and certifications to ensure they align with your requirements.

#3 Finished Product Customization

Customization is key to the line of work at Zemetal, and it should be a top consideration when choosing a laser edging service. For example, a provider that offers custom-fit solutions can adapt to the unique requirements of your project, ensuring that the final product meets your specific needs. Look for services that are willing to work closely with you to understand your objectives and offer tailored solutions.

#4 Turnaround Time

Turnaround time is a critical factor, especially in fast-paced industries. A laser edging service that can guarantee quick delivery without compromising on quality is invaluable. Assess their ability to meet tight deadlines while maintaining high standards. Fast turnaround times can significantly enhance your operational efficiency and help you meet your project timelines.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Meet Our Best Sheet Metal Fabrication Laser Cutting Blanking Stamping Weilding Bending Services

Connect with Us

Zemetal is committed to ensuring your privacy and promises prompt, secure responses to all your inquiries.