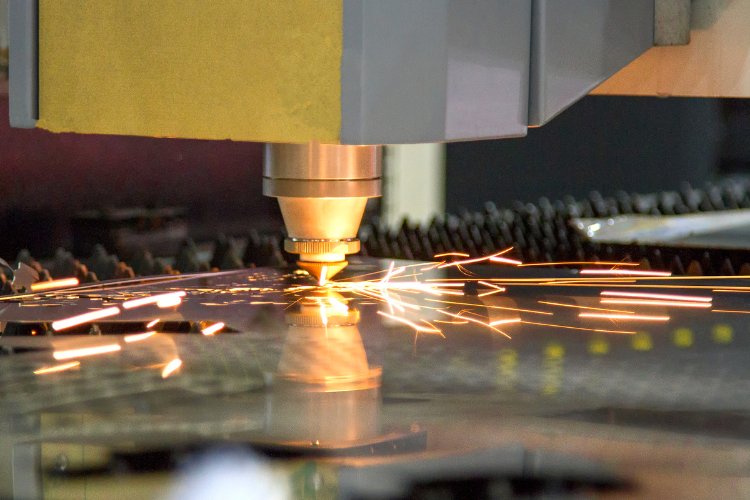

Laser Cutting Sheet Metal

Dive into our selection of top-tier metal services, where unparalleled quality meets innovative design. Each item in our range is a testament to our commitment to excellence in metal fabrication.

Explore Our Premium Metal Fabrication Range

At Zemetal, we pride ourselves on being at the forefront of metal fabrication technology, and our laser cutting services for sheet metal stand as a testament to this commitment. Our approach is grounded in precision, efficiency, and versatility, ensuring that we meet the diverse needs of our clients in the metal fabrication industry, including businesses, wholesalers, distributors, and other users of metal fabrication services.

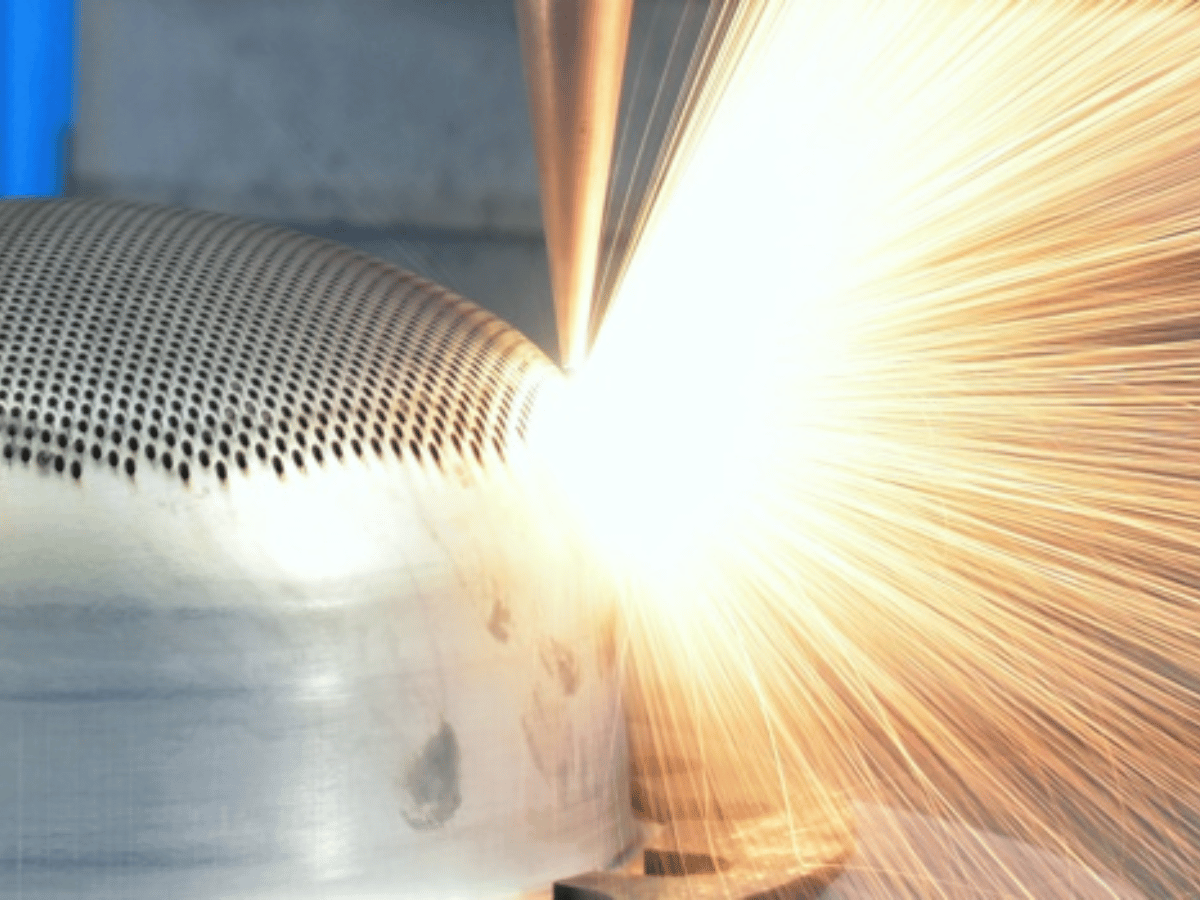

Laser cutting is more than just a process at Zemetal; it’s an art form. We harness advanced laser technology to deliver cuts that are not only precise but also clean and consistent. Our focus is not only on delivering quality results but also on optimizing production times and reducing costs, ensuring that our clients receive value that goes beyond the cut.

Zemetal: Who We Are

Our Founding Journey

Established with a vision to revolutionize the sheet metal processing industry, our journey reflects a blend of innovation, precision, and dedication. From our humble beginnings, we’ve evolved into a leader in sheet metal processing and batch production. Our success is built on a commitment to quality and relentless technological advancement, setting new standards in the industry.

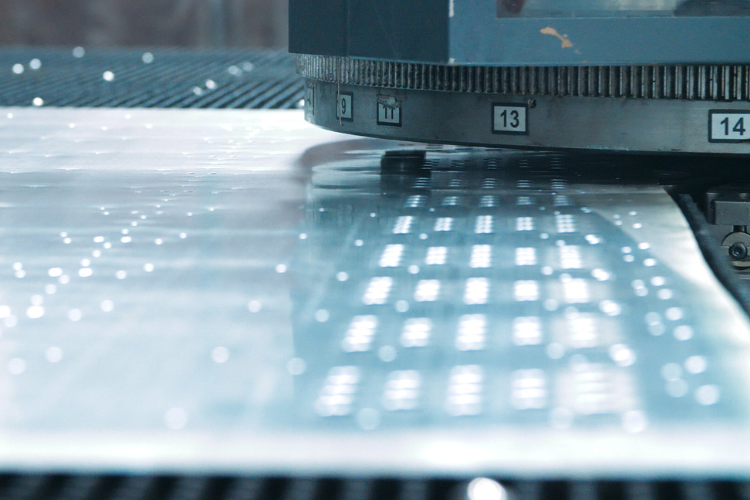

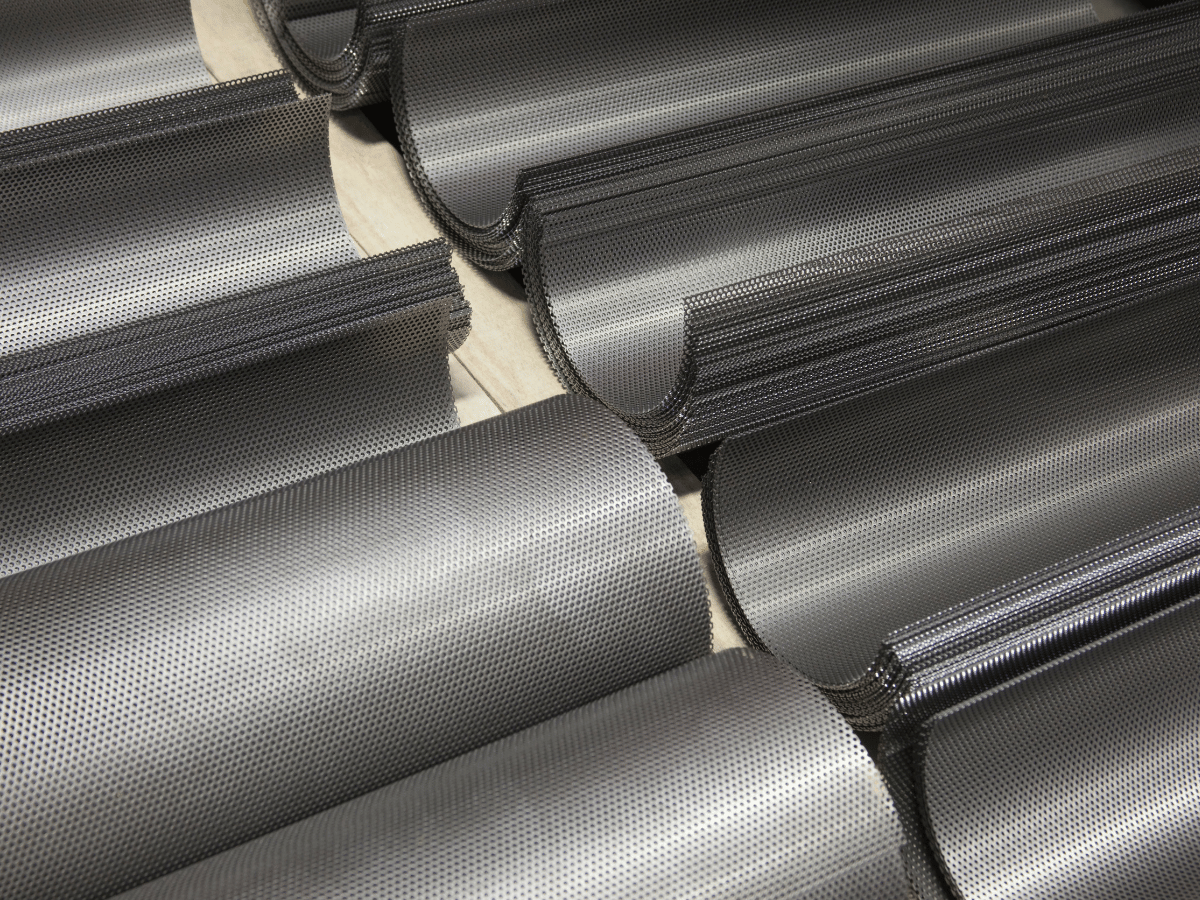

Inside Our Facility

Step into our state-of-the-art factory, where advanced technology meets skilled craftsmanship. Optimally designed for efficiency, our facility is the heart of our sheet metal production. We handle intricate designs and large-scale outputs with precision, ensuring every product meets the highest quality benchmarks. Our factory is a testament to our capability to handle diverse, high-volume demands with precision.

Innovation & Development

At the core of our operation is a robust Research & Development wing, pushing the frontiers of sheet metal processing. Our R&D team, equipped with cutting-edge tools and driven by innovation, continually develops new methods to enhance efficiency and product quality. This relentless pursuit of improvement sets us apart and ensures we stay ahead in a rapidly evolving industry.

Certification Excellence

Our commitment to excellence is affirmed by our comprehensive range of industry certifications. Each certificate represents our adherence to stringent quality standards, environmental practices, and safety protocols. These certifications are a promise to our clients that every sheet metal product we deliver is crafted to perfection, adhering to the highest industry benchmarks. Trust and quality are the pillars of our service.

Meet the Experts Behind Zemetal

01

Media Team

For content collaborations or to join our blog contributors, please contact [email protected]. We welcome fresh perspectives and are committed to enriching our metal sheet fabrication industry platform with diverse insights. Let’s innovate together.

02

Quality Assurance Team

In our Quality Assurance Team, we meticulously ensure a 99.8% precision rate in every project, embodying our dedication to superior quality and a zero-error approach in metal sheet fabrication.

03

Research & Development Team

Leading with over 30 innovative techniques, our R&D Team enhances fabrication efficiency and precision by 25%, constantly redefining creativity and scientific accuracy in metal sheet fabrication.

04

Engineering & Design Team

Our Engineering & Design Team, with over 500 bespoke projects, expertly fuses creative design with engineering precision, ensuring each fabrication project excels in functionality and aesthetics.

Empowering Goals With Us

At Zemetal, our partnership with a pioneering electric vehicle firm is a testament to our dedication to precision, sustainability, and efficiency. Utilizing our cutting-edge fabrication skills and eco-friendly practices, we played a pivotal role in addressing critical challenges faced by Mr. Frazier's company. This collaboration resulted in a staggering 30% enhancement in vehicle performance, marking a significant milestone in our journey towards innovative excellence.

Our collaboration with Mr. Virden's HVAC company is a shining example of Zemetal's commitment to delivering bespoke metal fabrication solutions that are both innovative and efficient. By embracing and solving unique architectural challenges, we not only improved the functionality of their HVAC systems but also seamlessly integrated them into the desired aesthetics. This strategic partnership led to substantial growth for our client, showcasing the transformative impact of our tailored solutions.

Working with Mr. Park and his team at the automotive company highlighted Zemetal's unwavering commitment to precision, innovation, and efficiency. By confronting their complex challenges with our advanced manufacturing techniques, we didn't just meet their high standards; we played a crucial role in significantly boosting their vehicle performance. This collaboration underscores our dedication to pushing the boundaries of what's possible in automotive excellence.

Previous

Next

Your Manufacturing Demands, Our Expert Solutions

Comprehensive Fabrication Services

Offering a wide range of metal fabrication services, from cutting and bending to welding and assembling, tailored

to your specific requirements.

Advanced Technology & Equipment

Utilizing state-of-the-art machinery and technology to ensure high precision and quality in every project, meeting the

most demanding manufacturing standards.

Expert Team & Quality Assurance

Our skilled professionals are committed to delivering excellence. We adhere to strict quality control protocols to

ensure top-notch results.

Flexible Production Capacity

Whether you need a single prototype or large-scale production, our flexible manufacturing processes can adapt to your project’s scale and complexity.

Timely Delivery & Customer Support

We understand the importance of deadlines. Our efficient processes and dedicated support team ensure timely delivery and ongoing communication throughout your project.

Sustainable Practices & Material Options

Committed to environmental responsibility, we offer sustainable manufacturing practices and a variety of material choices, including eco-friendly and recycled options, to meet both

your project needs and environmental goals.

Applicable Materials for Laser Cutting Sheet Metal

Stainless Steel

Stainless steel is the most popular choices for laser cutting machining due to its durability and resistance to corrosion. This material is ideal for applications that require longevity and strength, such as in the construction and automotive industries. At Zemetal, laser cutting technology is finely tuned to handle various grades and thicknesses of stainless steel sheet, ensuring precise cuts without compromising the material’s integrity.

Aluminum

Aluminum is known for being both lightweight and strong, characteristics that are particularly valued in the aerospace, transportation, and consumer electronics sectors. The main challenges when laser printing and cutting aluminum are its high reflectivity and thermal conductivity. However, advanced laser cutting techniques have been developed to overcome these challenges, enabling clean, precise cuts.

Mild Steel

Mild steel is a versatile and economical choice for laser engraving and cutting, especially suitable for industrial and architectural uses due to its strength and weldability. Modern laser cutting techniques are employed to improve the quality of cuts in mild steel, reducing burrs and minimizing thermal distortion. This adaptability in handling various thicknesses ensures high precision in each project.

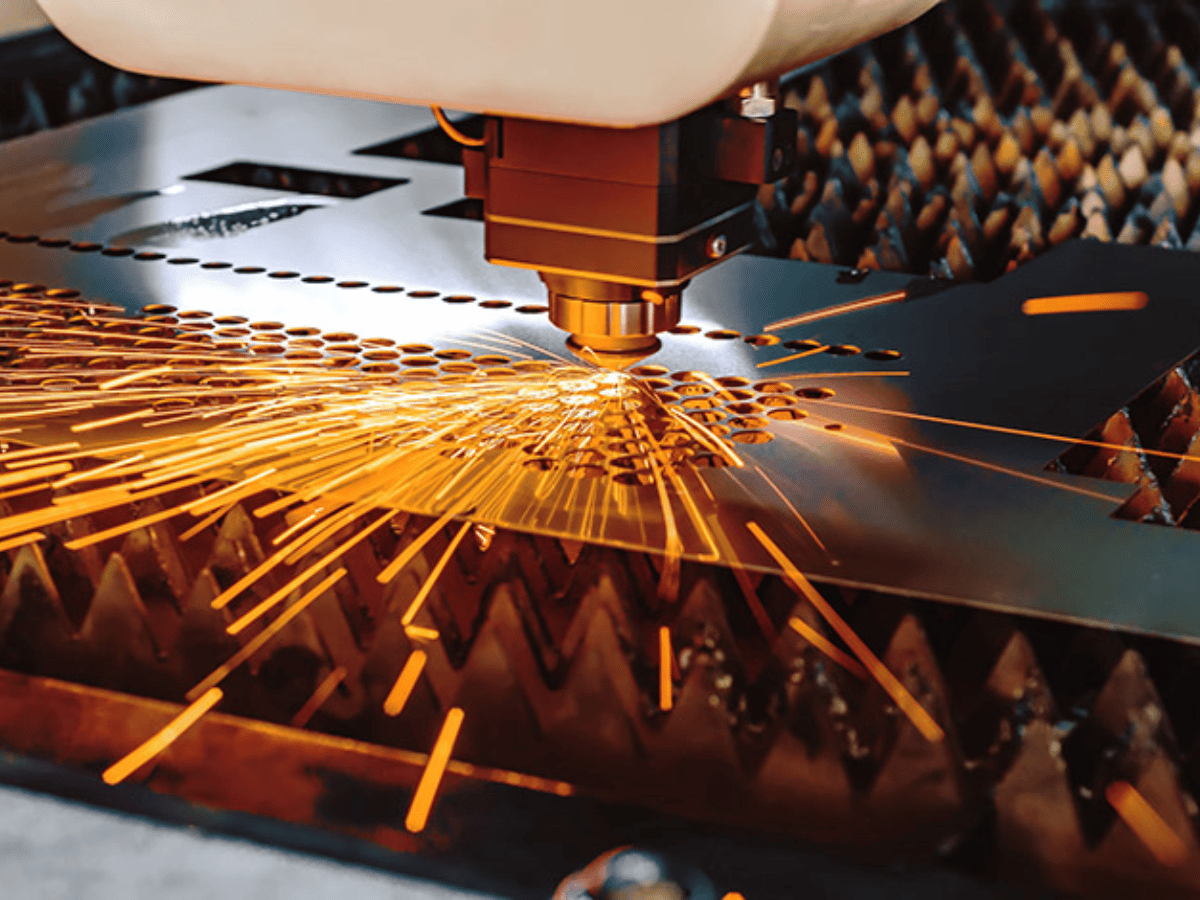

Features of Laser Cutting Sheet Metal

High Accuracy in Cutting

Laser cutting stands out for its exceptional accuracy, a feature crucial in metal fabrication. This precision allows for complex shapes and fine details to be cut with minimal tolerances, making it ideal for intricate designs and thin metals. At Zemetal, our advanced laser cutting technology ensures that every cut is made with the utmost precision, resulting in components that consistently meet or exceed client specifications.

Adapting to Various Metals with Ease

Versatility is a key advantage of laser cutting and fabrication, as it efficiently handles a wide range of materials. From stainless steel to aluminum and mild steel, laser cutting technology can adapt to different thicknesses and material properties, making it a versatile tool for various industrial applications.

Benefits of Laser Cutting Sheet Metal

Enhanced Production Speed with Minimal Waste

Efficiency in laser cutting is characterized by its rapid production capabilities. For instance, this speed significantly shortens production times, ideal for large-scale or urgent projects. Moreover, the accuracy of laser cutting leads to reduced material waste, contributing to cost-effectiveness and environmental sustainability.

Consistent Quality and Enhanced Aesthetic Appeal

Laser cutting is renowned for producing consistently high-quality outputs with aesthetically pleasing results. For instance, the technology ensures that each cut piece has clean edges and uniform dimensions, essential for projects requiring consistent quality. The aesthetic appeal of laser-cut items, characterized by their clean lines and smooth finishes, adds significant value to the final product.

Types of Laser Cutting Sheet Metal

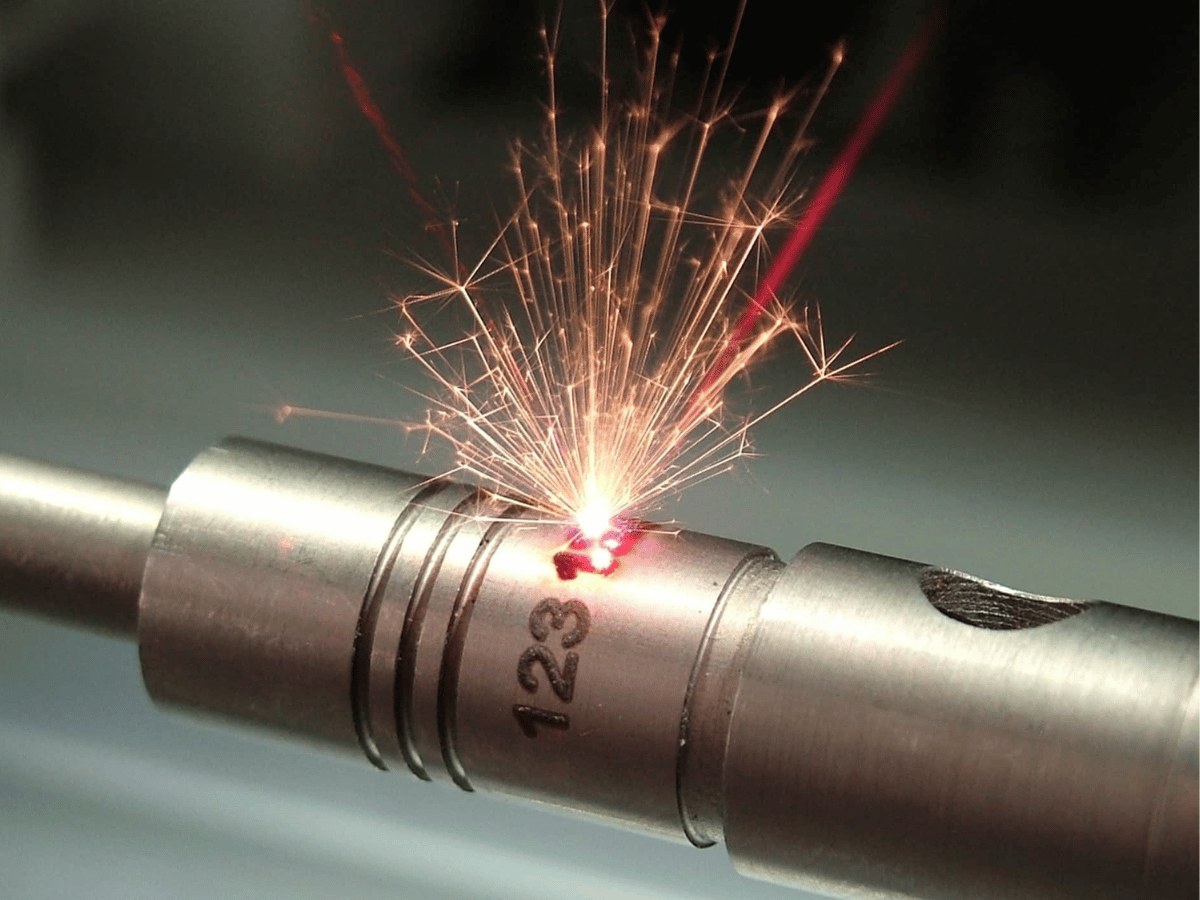

Laser Marking

According to Science Direct, laser marking is a precise process used to leave permanent marks on metal surfaces without cutting through the material. This technique is ideal for serial numbers, logos, and detailed graphics. It involves altering the metal surface to create high-contrast marks, ensuring legibility and durability. The process is highly efficient for identification and branding purposes on various metal products.

Laser Etching

Laser etching is a subset of laser marking, but it involves removing a portion of the metal surface to create a visible etch. At Zemetal, this technique is used for creating detailed designs, text, or images on metal surfaces. Laser etching is slightly deeper than laser marking and is particularly effective for creating long-lasting, visible patterns or designs on a variety of metal types, making it popular for decorative and functional applications.

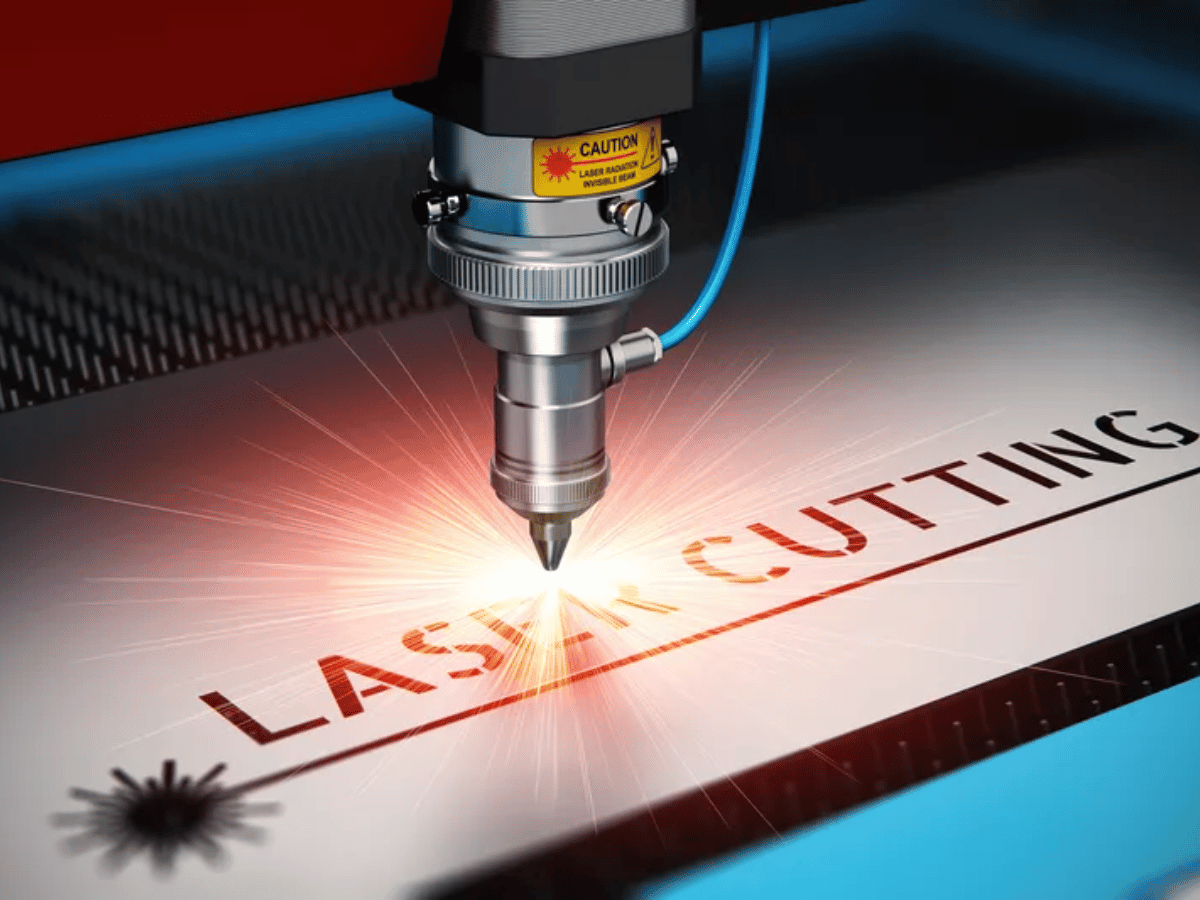

Laser CNC

According to Instructables, laser CNC refers to the use of computer-controlled laser cutting machines for precise cutting of sheet metal. This technology allows for intricate cutting, shaping, and drilling with high precision. The CNC aspect means that the process is automated and controlled by computer software, which translates digital designs into precise movements of the laser cutter.

Sheet Metal Laser Cutting Design

Step#1 Design and Planning

The first step in the sheet metal laser cutting process involves designing and planning. This stage requires creating a detailed design using CAD (Computer-Aided Design) software. The design is meticulously planned to ensure it meets the specific requirements of the project, considering factors like the type of metal, thickness, and end-use of the product.

Step#2 Material Selection and Preparation

Once the design is finalized, the next step is selecting and preparing the appropriate sheet metal. This involves choosing the right type of metal based on its properties, such as thickness, strength, and heat resistance. The metal sheet is then cleaned and prepared for cutting. Any surface treatments or coatings that may interfere with the laser cutting process are removed to ensure a clean, precise cut.

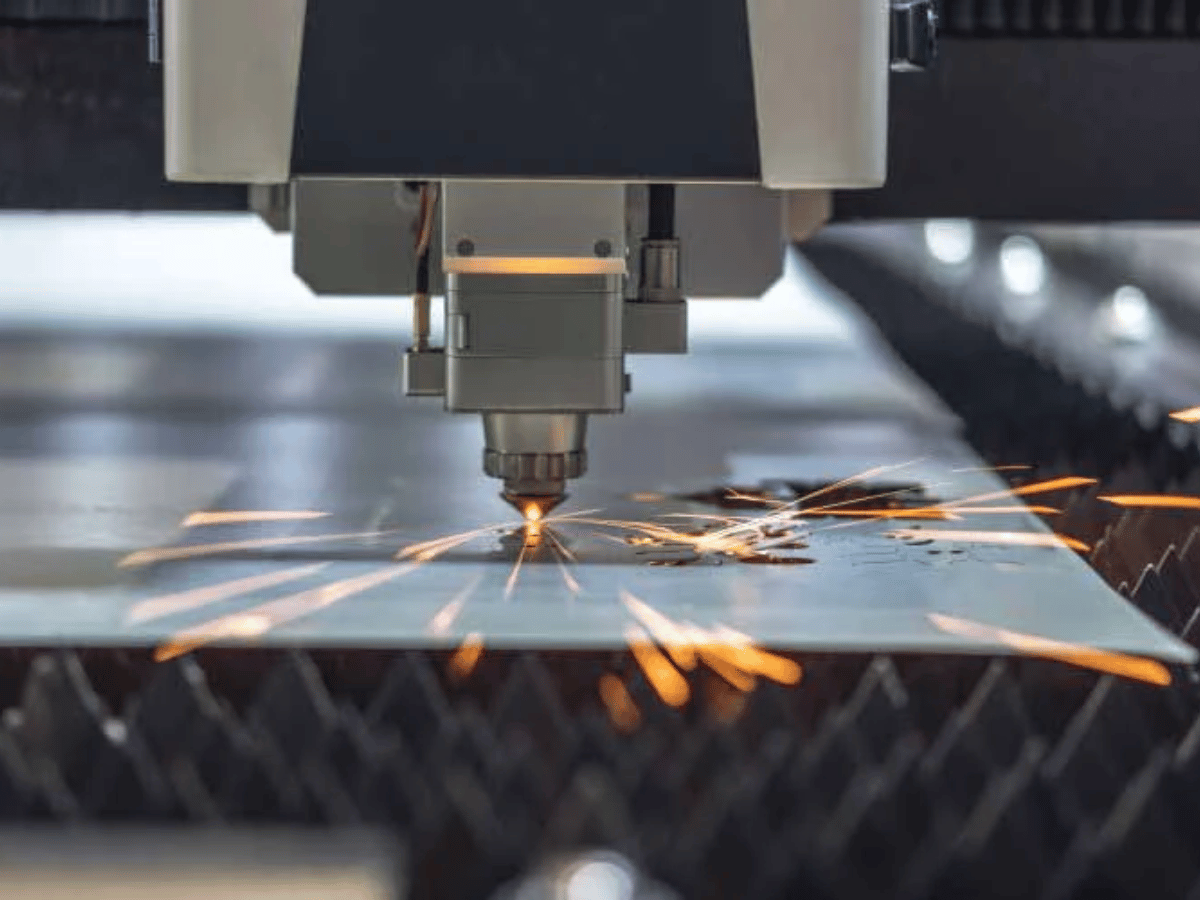

Step#3 Laser Cutting Execution

The third step is the actual laser cutting. The prepared metal sheet is placed in the laser cutting machine, and the previously designed CAD file is uploaded to the machine’s computer. The laser cutter then precisely follows the design, cutting the metal sheet with high accuracy. The laser beam melts, burns, or vaporizes the metal along the designated path, creating the desired shape or design.

Step#4 Quality Inspection and Finishing

After the cutting process is complete, the final step is quality inspection and finishing. At Zemetal, the cut pieces are inspected for accuracy, dimensions, and any potential defects. Any necessary post-processing, such as deburring or additional surface finishing, is carried out to ensure the final product meets quality standards.

Applications of Laser Cutting Sheet Metal

Automotive Industry

The automotive industry extensively employs laser cutting for manufacturing precise metal parts like exhaust systems and engine components. This technology’s accuracy is crucial for ensuring high-quality production.

Construction and Architecture

Laser cutting is used to create both structural and decorative elements. This allows for the production of intricate designs in laser cutting metal sheets, which are often used in building facades, decorative panels, and custom fittings. Zemetal’s expertise in laser cutting enables architects and builders to realize their creative visions, providing them with the flexibility to incorporate complex and unique metal designs in their projects.

Aerospace and Defense

The aerospace and defense industries require components that meet extremely high standards of precision and quality. Laser cutting is instrumental in producing parts that adhere to these stringent requirements. Components such as airframe structures, engine components, and intricate brackets are all made using laser cutting.

3 Things to Consider When Choosing Laser Cutting Sheet Metal Services

#1 Laser Cutting Technology and Cutting Accuracy

A critical factor in choosing a laser cutting service is the technology they employ and their ability to achieve high levels of cutting accuracy. This encompasses evaluating the sophistication of their laser cutting equipment, their proficiency in executing intricate designs with minimal error margins, and their history of delivering high-precision cuts.

#2 Compatibility with Different Metals

Different metals, such as stainless steel, aluminum, and mild steel, each react differently to laser cutting and require specialized handling. Selecting a provider like Zemetal, that have experience and knowledge in cutting your chosen material will guarantee optimal outcomes, maintaining the metal’s inherent qualities and meeting specific project requirements.

#3 Cost-Effectiveness of Laser Cutting Services

Consider the service provider’s efficiency in terms of production speed and cost-effectiveness. This involves assessing their ability to meet project deadlines, their capacity for handling large-scale or complex orders, and the overall value they offer. Cost-effectiveness doesn’t only refer to the price but also to the quality of work, material utilization, and any additional services they provide.

Dive Deeper Into Our Resources

Looking for more diverse service options? Browse through our handpicked selections:

Laser Engraving and Etching

For some insightful reads, we’ve curated a list of recommended articles just for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Meet Our Best Sheet Metal Fabrication Laser Cutting Blanking Stamping Weilding Bending Services

Connect with Us

Zemetal is committed to ensuring your privacy and promises prompt, secure responses to all your inquiries.